Cost-Benefit Analysis of High Flow Pleated Filters

Pros and Cons of Using High Flow Pleated Filters

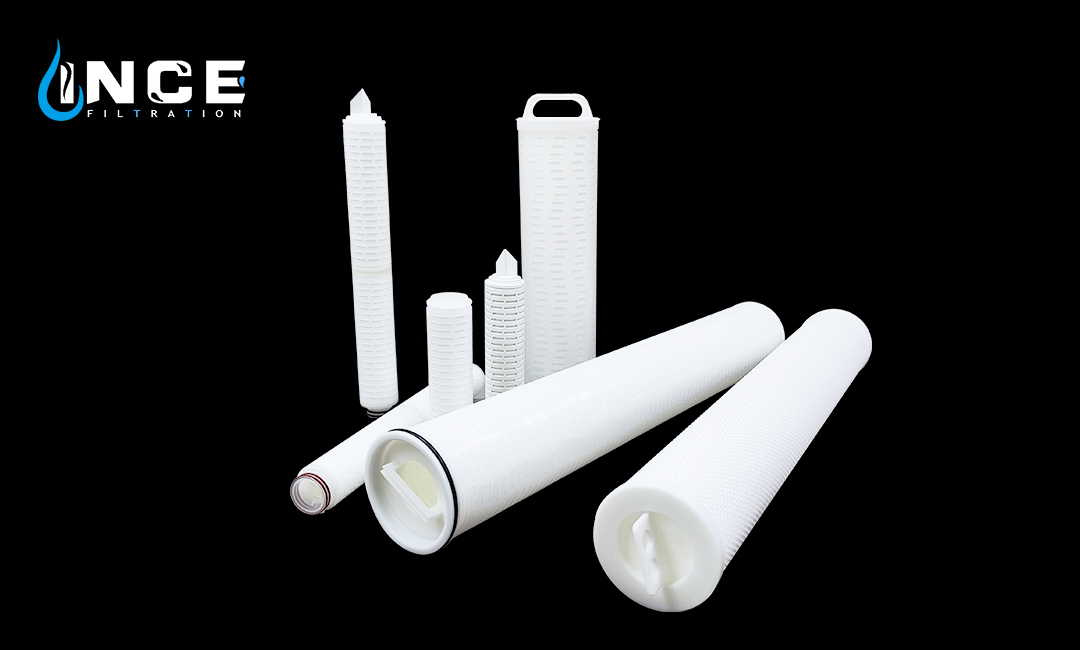

High flow pleated filters are a popular choice for many industries due to their efficiency in removing contaminants from liquids. These filters are designed to handle high flow rates while maintaining a high level of filtration, making them a cost-effective option for businesses looking to improve their filtration processes. In this article, we will explore the pros and cons of using high flow pleated filters in various applications.

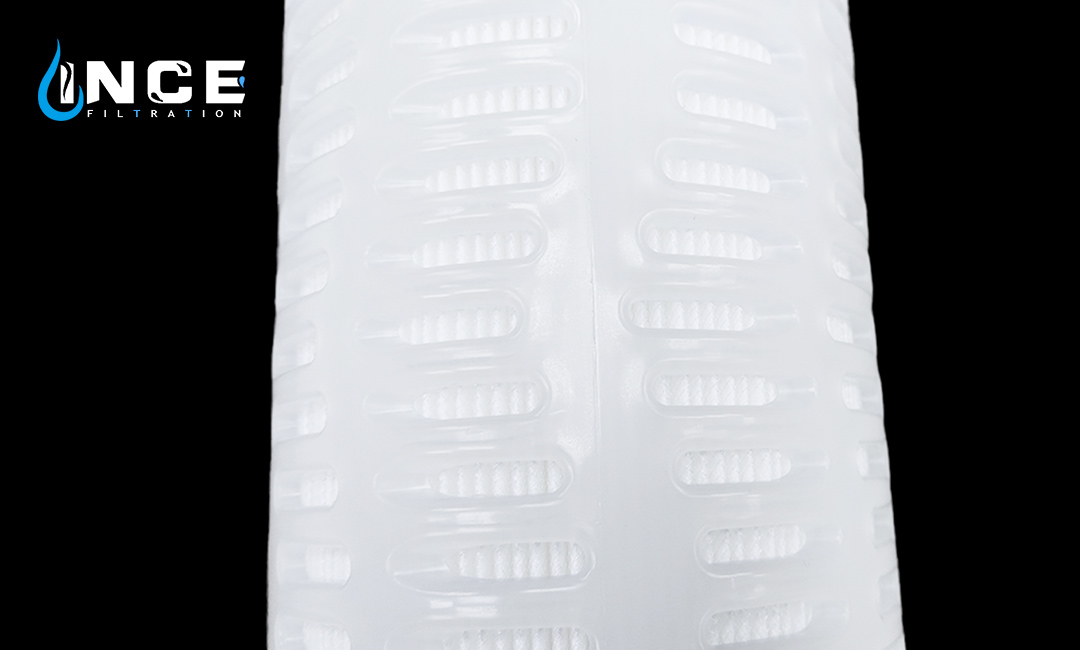

One of the main advantages of high flow pleated filters is their ability to handle a large volume of liquid flow. This makes them ideal for applications where a high flow rate is required, such as in industrial processes or water treatment plants. The pleated design of these filters allows for a larger surface area, which in turn increases the filtration capacity and efficiency. This means that fewer filters are needed to achieve the same level of filtration, resulting in cost savings for businesses.

Another benefit of high flow pleated filters is their long service life. These filters are designed to withstand high flow rates and are made from durable materials that can withstand harsh operating conditions. This means that they require less frequent replacement compared to other types of filters, reducing maintenance costs and downtime. Additionally, the pleated design of these filters allows for easy cleaning and maintenance, further extending their service life.

In terms of filtration efficiency, high flow pleated filters are highly effective at removing contaminants from liquids. The pleated design creates a large filtration area, allowing for the capture of particles of various sizes. This results in cleaner liquids and improved product quality, making these filters a valuable asset for businesses looking to maintain high standards of cleanliness and purity in their processes.

Despite their many advantages, high flow pleated filters also have some drawbacks that should be considered. One potential downside is their initial cost, which can be higher than other types of filters. However, it is important to consider the long-term cost savings that can be achieved through reduced maintenance and replacement costs when evaluating the overall cost-benefit of these filters.

Another potential drawback of high flow pleated filters is their size and weight. These filters are larger and heavier than other types of filters, which can make installation and handling more challenging. Businesses should consider the space and equipment requirements needed to accommodate these filters before making a decision to use them in their processes.

In conclusion, high flow pleated filters offer many benefits for businesses looking to improve their filtration processes. Their high flow rate, long service life, and efficient filtration make them a cost-effective option for a wide range of applications. While they may have some drawbacks, such as higher initial cost and size, the overall cost-benefit of using these filters is favorable for many businesses. By carefully evaluating their needs and considering the advantages and disadvantages of high flow pleated filters, businesses can make an informed decision on whether these filters are the right choice for their operations.

Cost Savings of Implementing High Flow Pleated Filters

High flow pleated filters are a critical component in many industrial processes, providing an effective means of removing contaminants from liquids and gases. While the initial cost of implementing high flow pleated filters may seem daunting, a cost-benefit analysis reveals that the long-term savings far outweigh the upfront investment.

One of the primary benefits of high flow pleated filters is their efficiency in removing contaminants from fluids. These filters are designed to have a larger surface area than traditional filters, allowing for greater filtration capacity and improved performance. As a result, high flow pleated filters can effectively capture particles of various sizes, ensuring that the fluid passing through them is clean and free of impurities.

In addition to their superior filtration capabilities, high flow pleated filters also offer significant cost savings over time. By effectively removing contaminants from fluids, these filters help to prolong the life of equipment and machinery, reducing the need for costly repairs and replacements. This not only saves money in the long run but also minimizes downtime and improves overall operational efficiency.

Furthermore, high flow pleated filters are designed to be durable and long-lasting, reducing the frequency of filter replacements and maintenance. This not only saves on the cost of purchasing new filters but also reduces labor costs associated with filter changes. In addition, the extended lifespan of high flow pleated filters means that they require less frequent monitoring and replacement, further reducing operational costs.

Another key advantage of high flow pleated filters is their energy efficiency. By improving the flow rate of fluids and reducing pressure drop, these filters help to optimize energy consumption and lower operating costs. This can result in significant savings over time, particularly for industries that rely heavily on fluid filtration for their processes.

When considering the cost-benefit analysis of high flow pleated filters, it is important to take into account the overall impact on operational efficiency and productivity. By ensuring that fluids are clean and free of contaminants, these filters help to maintain the quality of products and reduce the risk of equipment failure. This can lead to increased customer satisfaction, improved reputation, and ultimately, higher profits for the business.

In conclusion, the cost savings of implementing high flow pleated filters far outweigh the initial investment. By improving filtration efficiency, reducing maintenance costs, and optimizing energy consumption, these filters offer a cost-effective solution for industries looking to enhance their operational performance. With their superior performance and long-term benefits, high flow pleated filters are a wise investment for any business looking to improve their fluid filtration processes.

Factors to Consider When Conducting Cost-Benefit Analysis for High Flow Pleated Filters

High flow pleated filters are an essential component in many industrial processes, providing efficient filtration of liquids and gases. When considering the use of high flow pleated filters, it is important to conduct a cost-benefit analysis to determine if the investment is worthwhile. There are several factors to consider when conducting a cost-benefit analysis for high flow pleated filters.

One of the key factors to consider is the initial cost of the filters. High flow pleated filters can vary in price depending on the size, material, and efficiency of the filter. It is important to compare the initial cost of the filters with the potential savings that can be achieved through improved filtration efficiency and reduced maintenance costs.

Another important factor to consider is the lifespan of the filters. High flow pleated filters are designed to have a longer lifespan than traditional filters, which can result in cost savings over time. It is important to consider the expected lifespan of the filters and calculate the total cost of ownership over the lifespan of the filters.

Efficiency is another important factor to consider when conducting a cost-benefit analysis for high flow pleated filters. High flow pleated filters are designed to provide superior filtration efficiency, which can result in improved product quality and reduced downtime. It is important to calculate the potential cost savings that can be achieved through improved efficiency when comparing high flow pleated filters to traditional filters.

Maintenance costs are also an important factor to consider when conducting a cost-benefit analysis for high flow pleated filters. High flow pleated filters require less frequent maintenance than traditional filters, which can result in cost savings over time. It is important to consider the potential maintenance costs associated with high flow pleated filters and compare them to the maintenance costs of traditional filters.

In addition to cost savings, it is important to consider the potential benefits of using high flow pleated filters. High flow pleated filters can improve product quality, reduce downtime, and increase overall efficiency. It is important to consider these potential benefits when conducting a cost-benefit analysis for high flow pleated filters.

In conclusion, there are several factors to consider when conducting a cost-benefit analysis for high flow pleated filters. It is important to consider the initial cost, lifespan, efficiency, maintenance costs, and potential benefits of using high flow pleated filters. By carefully evaluating these factors, businesses can determine if the investment in high flow pleated filters is worthwhile.

Case Studies Demonstrating the Effectiveness of High Flow Pleated Filters in Cost Reduction

High flow pleated filters have become increasingly popular in industrial applications due to their ability to provide efficient filtration at a high flow rate. These filters are designed to handle large volumes of liquid while maintaining a high level of filtration efficiency. In this article, we will explore the cost-benefit analysis of using high flow pleated filters in various industries and how they can help in cost reduction.

One of the key benefits of high flow pleated filters is their long service life. These filters are designed to withstand high flow rates and can last much longer than traditional filters. This means that companies can save money on filter replacements and maintenance costs in the long run. Additionally, the high filtration efficiency of these filters ensures that contaminants are effectively removed from the liquid, reducing the risk of equipment damage and downtime.

In a case study conducted in a manufacturing plant, the use of high flow pleated filters resulted in a significant reduction in maintenance costs. The plant had been experiencing frequent filter replacements due to the high flow rates of the liquid being processed. By switching to high flow pleated filters, the plant was able to extend the service life of the filters and reduce the frequency of replacements. This led to a substantial cost savings for the company over time.

Another benefit of high flow pleated filters is their ability to improve overall system efficiency. These filters can handle higher flow rates without compromising on filtration efficiency, allowing companies to increase their production output without sacrificing quality. In a case study conducted in a food processing plant, the use of high flow pleated filters resulted in a 20% increase in production output. This increase in efficiency not only helped the plant meet growing demand but also reduced operating costs per unit produced.

Furthermore, high flow pleated filters can help companies reduce their environmental impact. By effectively removing contaminants from the liquid, these filters help companies comply with environmental regulations and reduce the risk of pollution. In a case study conducted in a wastewater treatment plant, the use of high flow pleated filters resulted in a significant reduction in the amount of pollutants discharged into the environment. This not only helped the plant avoid costly fines but also improved its reputation as a responsible corporate citizen.

In conclusion, the cost-benefit analysis of high flow pleated filters demonstrates their effectiveness in cost reduction across various industries. These filters offer long service life, improved system efficiency, and environmental benefits, making them a valuable investment for companies looking to optimize their filtration processes. By incorporating high flow pleated filters into their operations, companies can save money on maintenance costs, increase production output, and reduce their environmental impact. Overall, high flow pleated filters are a cost-effective solution for companies looking to improve their filtration processes and achieve long-term cost savings.