Exploring the Durability of Polyester Spiral Fabric in High-Temperature Environments

Polyester Spiral Fabric: Heat Resistance and Performance

Polyester spiral fabric has gained significant attention in various industrial applications due to its remarkable heat resistance and performance characteristics, particularly in high-temperature environments. This fabric, composed of polyester fibers, is engineered to withstand extreme thermal conditions while maintaining its structural integrity and functionality. The inherent properties of polyester, such as its high melting point and excellent dimensional stability, contribute to its suitability for applications where exposure to elevated temperatures is a concern.

One of the key advantages of polyester spiral fabric is its ability to resist degradation when subjected to heat. Unlike many other materials that may warp, shrink, or lose their mechanical properties under high temperatures, polyester maintains its strength and flexibility. This resilience is particularly important in industries such as aerospace, automotive, and manufacturing, where components are often exposed to fluctuating thermal conditions. The fabric’s ability to endure these stresses without compromising performance makes it an ideal choice for applications ranging from insulation to protective coverings.

Moreover, the manufacturing process of polyester spiral fabric enhances its heat resistance. The fibers are often treated with specialized coatings that further improve their thermal stability. These treatments not only bolster the fabric’s ability to withstand high temperatures but also provide additional benefits such as increased resistance to chemicals and moisture. As a result, polyester spiral fabric can be utilized in environments where exposure to harsh substances is prevalent, ensuring longevity and reliability.

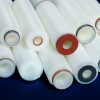

In addition to its heat resistance, polyester spiral fabric exhibits excellent performance characteristics that are essential in high-temperature applications. The fabric’s lightweight nature allows for easy handling and installation, which is a significant advantage in industries where efficiency is paramount. Furthermore, its flexibility enables it to conform to various shapes and surfaces, making it suitable for a wide range of applications, including conveyor belts, filtration systems, and protective barriers.

Another noteworthy aspect of polyester spiral fabric is its ability to maintain its performance over time. Unlike some materials that may degrade or lose their effectiveness after prolonged exposure to heat, polyester retains its properties, ensuring consistent performance throughout its lifespan. This durability translates to reduced maintenance costs and increased operational efficiency, as businesses can rely on polyester spiral fabric to perform reliably in demanding conditions.

The versatility of polyester spiral fabric extends beyond its heat resistance and performance. It can be engineered to meet specific requirements, such as varying thicknesses, weaves, and coatings, allowing for customization based on the unique needs of different applications. This adaptability makes it a preferred choice for engineers and designers seeking materials that can withstand the rigors of high-temperature environments while providing optimal performance.

In conclusion, the durability of polyester spiral fabric in high-temperature environments is a testament to its exceptional heat resistance and performance capabilities. Its ability to withstand extreme thermal conditions without compromising structural integrity, combined with its lightweight and flexible nature, makes it an invaluable material in various industrial applications. As industries continue to evolve and demand more resilient materials, polyester spiral fabric stands out as a reliable solution, ensuring that it remains a key player in the realm of high-temperature applications. The ongoing advancements in polyester technology further promise to enhance its properties, solidifying its position as a material of choice for future innovations.

Applications of Polyester Spiral Fabric in High-Temperature Settings

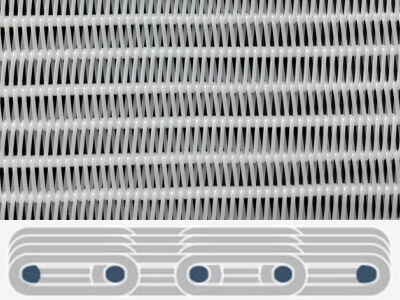

Polyester spiral fabric has emerged as a versatile material, particularly in high-temperature environments where durability and resilience are paramount. This fabric, characterized by its unique spiral construction, offers a range of applications that capitalize on its ability to withstand extreme conditions. One of the most notable applications of polyester spiral fabric is in the industrial sector, where it is frequently used in the manufacturing of filtration systems. These systems are essential for maintaining air quality and ensuring the efficient operation of machinery in environments that experience elevated temperatures. The fabric’s inherent resistance to heat and chemical degradation makes it an ideal choice for filters that must endure prolonged exposure to harsh conditions.

In addition to filtration, polyester spiral fabric is also utilized in the production of conveyor belts. These belts are critical in various industries, including food processing, mining, and manufacturing, where they transport materials through high-temperature processes. The strength and flexibility of polyester spiral fabric allow for the creation of conveyor belts that can handle heavy loads while maintaining their structural integrity. This capability is particularly important in settings where temperature fluctuations can lead to material expansion and contraction, potentially compromising the performance of less durable materials.

Another significant application of polyester spiral fabric is in the construction of protective covers and tarps. In industries such as construction and agriculture, equipment and materials often require protection from extreme temperatures and environmental factors. Polyester spiral fabric provides a robust solution, as it is not only heat-resistant but also lightweight and easy to handle. This combination of properties ensures that protective covers can be deployed quickly and effectively, safeguarding valuable assets from damage caused by high temperatures and UV exposure.

Moreover, the textile’s adaptability extends to the automotive sector, where it is used in the production of heat shields and insulation materials. These components are crucial for protecting sensitive parts of vehicles from the intense heat generated by engines and exhaust systems. The ability of polyester spiral fabric to maintain its structural integrity under high temperatures ensures that it can effectively serve as a barrier, enhancing the overall safety and performance of automotive systems.

In the realm of aerospace, polyester spiral fabric finds its place in the manufacturing of thermal protection systems. These systems are designed to shield spacecraft and aircraft from the extreme temperatures encountered during flight and re-entry. The lightweight nature of polyester spiral fabric, combined with its thermal resistance, makes it an ideal candidate for applications where weight savings are critical without compromising safety and performance.

Furthermore, the versatility of polyester spiral fabric is evident in its use in the production of industrial curtains and partitions. In manufacturing facilities, these curtains help to create controlled environments, separating areas that require different temperature settings. The durability of polyester spiral fabric ensures that these partitions can withstand the rigors of daily use while maintaining their effectiveness in high-temperature settings.

In conclusion, the applications of polyester spiral fabric in high-temperature environments are diverse and impactful. From filtration systems and conveyor belts to protective covers and automotive components, this fabric demonstrates remarkable durability and resilience. Its ability to withstand extreme conditions makes it an invaluable material across various industries, ensuring that operations can continue smoothly and safely even in the most challenging environments. As industries continue to evolve and face new challenges, the role of polyester spiral fabric is likely to expand, further solidifying its position as a critical material in high-temperature applications.

Comparing Durability: Polyester Spiral Fabric vs. Other Materials in Extreme Heat

Polyester spiral fabric has gained significant attention in various industries due to its remarkable durability, particularly in high-temperature environments. When comparing polyester spiral fabric to other materials, it becomes evident that its unique properties make it a superior choice for applications exposed to extreme heat. One of the primary advantages of polyester spiral fabric is its inherent resistance to thermal degradation. Unlike natural fibers, which can weaken and lose structural integrity when subjected to high temperatures, polyester maintains its strength and flexibility, ensuring longevity and reliability in demanding conditions.

In contrast, materials such as cotton or wool tend to absorb moisture, which can lead to a decrease in their performance when exposed to heat. The moisture retention in these natural fibers can cause them to become brittle and less effective in high-temperature applications. Polyester spiral fabric, on the other hand, exhibits low moisture absorption, allowing it to perform consistently without the risk of degradation due to humidity or heat. This characteristic is particularly beneficial in environments where temperature fluctuations are common, as it ensures that the fabric remains stable and functional.

Moreover, polyester spiral fabric is engineered to withstand not only high temperatures but also the mechanical stresses associated with extreme conditions. When compared to other synthetic materials, such as nylon, polyester demonstrates superior resistance to heat and UV radiation. While nylon can begin to lose its structural integrity at elevated temperatures, polyester remains stable, making it an ideal choice for applications such as industrial filtration, heat shields, and protective clothing. The ability of polyester spiral fabric to endure prolonged exposure to high temperatures without compromising its performance is a testament to its durability.

Another critical aspect to consider is the ease of maintenance associated with polyester spiral fabric. Unlike some other materials that may require special cleaning methods or treatments to maintain their integrity, polyester is relatively easy to clean and care for. This ease of maintenance not only extends the lifespan of the fabric but also reduces the overall cost of ownership, making it a practical choice for industries that rely on durable materials. In high-temperature environments, where equipment and materials are often subjected to harsh conditions, the ability to maintain the fabric’s performance with minimal effort is a significant advantage.

Furthermore, the versatility of polyester spiral fabric allows it to be used in a wide range of applications, from automotive to aerospace industries. Its adaptability to various manufacturing processes, such as weaving and knitting, enables the creation of specialized products tailored to specific high-temperature requirements. This flexibility is not always present in other materials, which may be limited in their applications due to their inherent properties. As industries continue to evolve and demand more from their materials, polyester spiral fabric stands out as a reliable option that meets the challenges posed by extreme heat.

In conclusion, the durability of polyester spiral fabric in high-temperature environments is unmatched when compared to other materials. Its resistance to thermal degradation, low moisture absorption, mechanical strength, ease of maintenance, and versatility make it an ideal choice for a variety of applications. As industries seek materials that can withstand the rigors of extreme conditions, polyester spiral fabric emerges as a frontrunner, offering a combination of performance and reliability that is essential for success in demanding environments. The ongoing advancements in polyester technology further enhance its capabilities, ensuring that it remains a vital component in the quest for durable materials in high-temperature applications.