How Polyester Spiral Drying Fabric Improves Manufacturing Efficiency

Reduced Drying Time

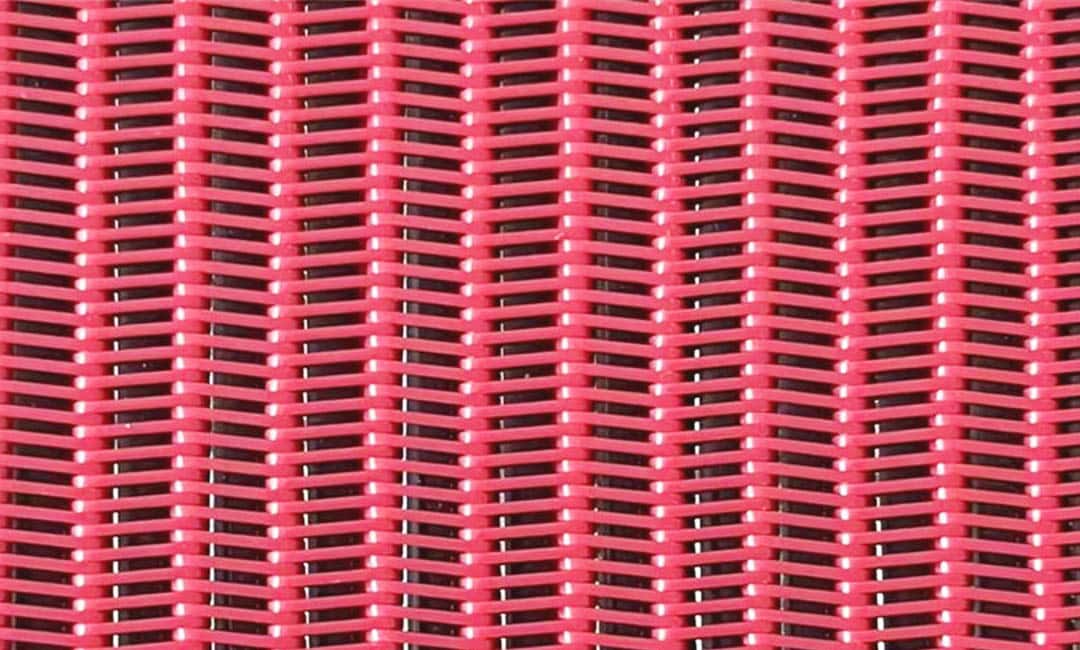

Polyester spiral drying fabric is a key component in the manufacturing process of various industries, particularly in the textile and paper industries. This specialized fabric is designed to efficiently remove moisture from materials during the drying process, ultimately improving manufacturing efficiency. One of the primary benefits of using polyester spiral drying fabric is its ability to reduce drying time significantly.

By utilizing polyester spiral drying fabric, manufacturers can expedite the drying process, allowing for faster production cycles and increased output. This is particularly advantageous in industries where time is of the essence, such as in the production of paper or textiles. The unique design of polyester spiral drying fabric allows for optimal air flow and heat distribution, ensuring that materials dry evenly and quickly.

In addition to reducing drying time, polyester spiral drying fabric also helps to improve the overall quality of the dried materials. By removing moisture efficiently and evenly, this specialized fabric helps to prevent over-drying or under-drying, which can lead to product defects or inconsistencies. This ultimately results in higher-quality finished products that meet or exceed industry standards.

Furthermore, the use of polyester spiral drying fabric can lead to cost savings for manufacturers. By reducing drying time and improving the quality of dried materials, manufacturers can increase their production output without compromising on product quality. This can result in lower production costs and higher profit margins, making polyester spiral drying fabric a valuable investment for businesses looking to improve their manufacturing efficiency.

Another key advantage of polyester spiral drying fabric is its durability and longevity. This specialized fabric is designed to withstand high temperatures and heavy use, making it ideal for continuous operation in industrial settings. Unlike traditional drying fabrics, polyester spiral drying fabric is resistant to wear and tear, ensuring long-lasting performance and reliability.

Overall, the use of polyester spiral drying fabric offers numerous benefits for manufacturers looking to improve their efficiency and productivity. By reducing drying time, improving product quality, and lowering production costs, this specialized fabric can help businesses stay competitive in today’s fast-paced manufacturing environment. With its durability and longevity, polyester spiral drying fabric is a smart investment for any industry looking to streamline their production processes and achieve greater success.

Increased Production Speed

Polyester spiral drying fabric is a key component in the manufacturing process of various industries, including paper, food, and pharmaceuticals. This specialized fabric is designed to withstand high temperatures and provide a smooth surface for materials to pass through during the drying process. By utilizing polyester spiral drying fabric, manufacturers can significantly improve their production efficiency and output.

One of the primary benefits of using polyester spiral drying fabric is its ability to increase production speed. The smooth surface of the fabric allows materials to move through the drying process quickly and efficiently, reducing the overall time it takes to produce a finished product. This increased speed not only allows manufacturers to meet tight deadlines but also enables them to produce more goods in a shorter amount of time.

In addition to speeding up the production process, polyester spiral drying fabric also helps to improve the quality of the finished product. The even distribution of heat and airflow provided by the fabric ensures that materials are dried evenly and thoroughly, resulting in a higher-quality end product. This is particularly important in industries such as paper manufacturing, where the quality of the final product is crucial to its performance and durability.

Furthermore, polyester spiral drying fabric is highly durable and long-lasting, making it a cost-effective solution for manufacturers looking to improve their efficiency. Unlike other types of drying fabrics, polyester spiral drying fabric can withstand high temperatures and heavy use without deteriorating or losing its effectiveness. This durability not only reduces the need for frequent replacements but also minimizes downtime due to fabric maintenance or repairs.

Another key advantage of using polyester spiral drying fabric is its versatility. This fabric can be customized to meet the specific needs of different industries, allowing manufacturers to tailor their drying processes to achieve optimal results. Whether it’s adjusting the fabric’s width, length, or airflow properties, polyester spiral drying fabric can be modified to suit a wide range of manufacturing applications.

Moreover, polyester spiral drying fabric is easy to install and maintain, further enhancing its appeal to manufacturers. The fabric can be quickly and easily integrated into existing production lines, minimizing disruption to operations. Additionally, its smooth surface makes it easy to clean and maintain, reducing the time and effort required to keep the fabric in optimal working condition.

In conclusion, polyester spiral drying fabric is a valuable tool for manufacturers looking to improve their production efficiency. By increasing production speed, improving product quality, and offering durability and versatility, this specialized fabric can help companies streamline their manufacturing processes and boost their overall output. With its numerous benefits and cost-effective nature, polyester spiral drying fabric is a smart investment for any manufacturer looking to enhance their efficiency and competitiveness in today’s fast-paced market.

Energy Efficiency

Polyester spiral drying fabric is a key component in the manufacturing process of various industries, including paper, food, and pharmaceuticals. This innovative fabric is designed to improve manufacturing efficiency by enhancing the drying process, reducing energy consumption, and increasing productivity. In this article, we will explore how polyester spiral drying fabric can benefit manufacturers and contribute to a more sustainable production environment.

One of the primary advantages of polyester spiral drying fabric is its ability to enhance the drying process. This fabric is specifically engineered to allow for optimal air flow, which helps to remove moisture from the product being manufactured more efficiently. By facilitating faster drying times, polyester spiral drying fabric can significantly reduce production cycle times and increase overall productivity. This is particularly beneficial for industries that rely on quick turnaround times to meet customer demands and stay competitive in the market.

In addition to improving drying efficiency, polyester spiral drying fabric also plays a crucial role in reducing energy consumption. Traditional drying methods often require high temperatures and prolonged drying times, which can lead to excessive energy usage and increased operating costs. By using polyester spiral drying fabric, manufacturers can achieve the same level of drying effectiveness at lower temperatures, resulting in significant energy savings. This not only helps to reduce operational expenses but also contributes to a more sustainable manufacturing process by lowering carbon emissions and minimizing environmental impact.

Furthermore, polyester spiral drying fabric is highly durable and long-lasting, making it a cost-effective solution for manufacturers looking to improve their production efficiency. Unlike traditional drying fabrics that may wear out quickly and require frequent replacement, polyester spiral drying fabric is designed to withstand the rigors of continuous use and maintain its effectiveness over time. This durability not only reduces maintenance costs but also ensures consistent drying performance, allowing manufacturers to achieve reliable and high-quality results with minimal downtime.

Another key benefit of polyester spiral drying fabric is its versatility and adaptability to different manufacturing processes. This fabric can be customized to meet specific production requirements, such as varying product sizes, shapes, and moisture content levels. By tailoring the design of the fabric to suit the unique needs of each manufacturing operation, manufacturers can optimize their drying processes and achieve maximum efficiency. This flexibility allows for greater control over the production process and enables manufacturers to adapt quickly to changing market demands and customer preferences.

In conclusion, polyester spiral drying fabric is a valuable asset for manufacturers seeking to improve their production efficiency and reduce energy consumption. By enhancing the drying process, lowering operating costs, and increasing productivity, this innovative fabric offers a sustainable solution for optimizing manufacturing operations. With its durability, versatility, and cost-effectiveness, polyester spiral drying fabric is a smart investment for manufacturers looking to stay ahead in today’s competitive market. By incorporating this advanced fabric into their production processes, manufacturers can achieve significant improvements in efficiency, sustainability, and overall performance.