How Spiral Filter Belts Optimize Wastewater Filtration

Enhanced Filtration Efficiency of Spiral Filter Belts

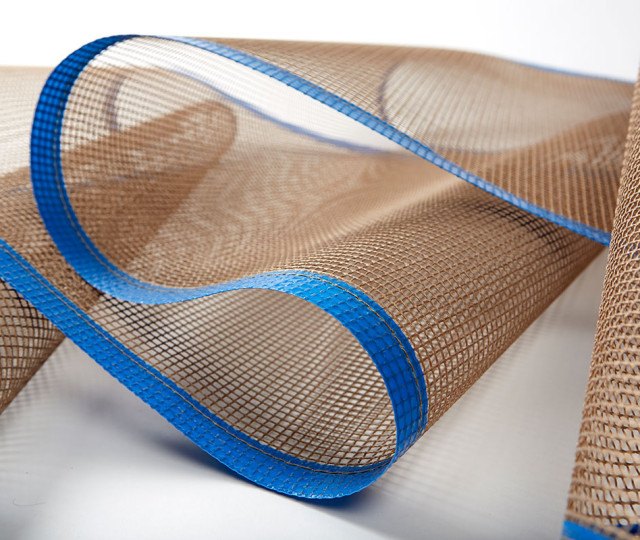

Spiral filter belts have emerged as a pivotal innovation in the realm of wastewater filtration, significantly enhancing the efficiency of the filtration process. These belts, characterized by their unique spiral design, facilitate a more effective separation of solids from liquids, thereby improving the overall quality of treated water. The design of spiral filter belts allows for a larger surface area compared to traditional filtration methods, which directly contributes to their enhanced filtration capabilities. This increased surface area enables the belts to capture more particulate matter, resulting in a higher retention rate of solids during the filtration process.

Moreover, the construction of spiral filter belts often incorporates advanced materials that are resistant to wear and tear, ensuring longevity and reliability in various wastewater treatment environments. This durability is crucial, as wastewater can contain abrasive particles that may degrade less robust filtration systems. By utilizing materials that withstand such conditions, spiral filter belts maintain their structural integrity over time, which is essential for consistent performance. As a result, facilities employing these belts can expect reduced maintenance costs and less frequent replacements, ultimately leading to more efficient operations.

In addition to their robust construction, spiral filter belts are designed to optimize flow dynamics within the filtration system. The spiral configuration promotes a uniform distribution of wastewater across the belt’s surface, minimizing the risk of clogging and ensuring that all areas of the belt are utilized effectively. This uniform flow not only enhances the filtration process but also reduces the energy consumption associated with pumping wastewater through the system. Consequently, facilities can achieve significant cost savings while simultaneously improving their environmental footprint.

Another critical aspect of spiral filter belts is their ability to facilitate the removal of a wide range of contaminants, including organic matter, suspended solids, and even certain pathogens. This versatility makes them suitable for various applications, from municipal wastewater treatment plants to industrial facilities dealing with complex effluents. The effectiveness of spiral filter belts in capturing diverse contaminants is further enhanced by their ability to operate in conjunction with other treatment technologies, such as biological treatment processes. By integrating spiral filter belts into a multi-barrier approach, facilities can achieve higher levels of purification, ensuring compliance with stringent regulatory standards.

Furthermore, the operational flexibility of spiral filter belts allows for adjustments in filtration parameters, such as flow rate and pressure, to accommodate varying influent characteristics. This adaptability is particularly beneficial in environments where wastewater composition can fluctuate significantly. By fine-tuning these parameters, operators can optimize the filtration process in real-time, ensuring that the system remains efficient and effective under changing conditions.

The implementation of spiral filter belts also contributes to the overall sustainability of wastewater treatment processes. By improving the efficiency of solid-liquid separation, these belts reduce the volume of sludge generated during treatment, which in turn decreases the costs associated with sludge handling and disposal. Additionally, the enhanced quality of treated water produced by spiral filter belts can lead to increased opportunities for water reuse, further promoting sustainable water management practices.

In conclusion, the enhanced filtration efficiency of spiral filter belts represents a significant advancement in wastewater treatment technology. Their unique design, durable materials, and operational flexibility collectively contribute to improved performance and sustainability in filtration processes. As the demand for effective wastewater management continues to grow, the adoption of spiral filter belts is likely to play a crucial role in meeting these challenges, ensuring cleaner water and a healthier environment for future generations.

Cost-Effectiveness of Spiral Filter Belts in Wastewater Treatment

In the realm of wastewater treatment, the efficiency and cost-effectiveness of filtration systems play a crucial role in ensuring that facilities can meet regulatory standards while managing operational expenses. One innovative solution that has gained traction in recent years is the use of spiral filter belts. These belts are designed to enhance the filtration process, providing a reliable means of separating solids from liquids in various wastewater applications. The cost-effectiveness of spiral filter belts can be attributed to several key factors, including their durability, reduced maintenance requirements, and improved operational efficiency.

To begin with, the durability of spiral filter belts significantly contributes to their cost-effectiveness. Constructed from high-quality materials, these belts are engineered to withstand the harsh conditions often found in wastewater treatment environments. This resilience not only extends the lifespan of the belts but also reduces the frequency of replacements. Consequently, facilities can save on both material costs and labor associated with the installation of new belts. Furthermore, the robust design of spiral filter belts minimizes the risk of breakdowns, which can lead to costly downtime and disruptions in the treatment process.

In addition to their durability, spiral filter belts require less maintenance compared to traditional filtration systems. The design of these belts allows for easier cleaning and less frequent servicing, which translates to lower operational costs. Facilities can allocate fewer resources to maintenance tasks, allowing staff to focus on other critical aspects of wastewater management. This reduction in maintenance not only saves money but also enhances the overall efficiency of the treatment process. As a result, facilities can achieve higher throughput rates without incurring significant additional costs.

Moreover, the operational efficiency of spiral filter belts plays a pivotal role in their cost-effectiveness. These belts are designed to optimize the filtration process, allowing for the effective removal of solids while maintaining a high flow rate of liquid. This efficiency means that facilities can process larger volumes of wastewater in a shorter amount of time, ultimately leading to increased productivity. The ability to handle higher volumes without compromising on filtration quality ensures that facilities can meet regulatory requirements while minimizing the costs associated with additional treatment processes.

Another aspect to consider is the energy efficiency of spiral filter belts. Traditional filtration systems often require substantial energy input to operate, which can lead to high utility bills. In contrast, spiral filter belts are designed to operate with lower energy consumption, further enhancing their cost-effectiveness. By reducing energy costs, facilities can improve their overall financial performance while also contributing to sustainability efforts. This energy efficiency aligns with the growing emphasis on environmentally responsible practices within the wastewater treatment industry.

In conclusion, the cost-effectiveness of spiral filter belts in wastewater treatment is a multifaceted advantage that encompasses durability, reduced maintenance, operational efficiency, and energy savings. As facilities strive to optimize their processes and manage costs effectively, the adoption of spiral filter belts presents a compelling solution. By investing in this innovative technology, wastewater treatment facilities can not only enhance their filtration capabilities but also achieve significant long-term savings. Ultimately, the integration of spiral filter belts into wastewater treatment systems represents a strategic move towards more efficient and cost-effective operations, ensuring that facilities can meet the challenges of modern wastewater management with confidence.

Durability and Maintenance Benefits of Spiral Filter Belts

Spiral filter belts have emerged as a pivotal component in the realm of wastewater filtration, offering a multitude of advantages that significantly enhance the durability and maintenance of filtration systems. One of the primary benefits of spiral filter belts is their robust construction, which is designed to withstand the harsh conditions often present in wastewater treatment facilities. These belts are typically made from high-quality materials that resist wear and tear, ensuring a longer lifespan compared to traditional filtration media. This durability not only reduces the frequency of replacements but also minimizes downtime, allowing facilities to operate more efficiently.

In addition to their inherent strength, spiral filter belts are engineered to provide consistent performance over time. The unique design of these belts allows for optimal flow rates and effective solids removal, which is crucial in maintaining the quality of treated water. As wastewater passes through the spiral filter belt, the filtration process is enhanced by the belt’s ability to create a uniform surface area for solids to be captured. This efficiency translates into less clogging and fewer maintenance interventions, further contributing to the overall reliability of the system.

Moreover, the maintenance benefits of spiral filter belts cannot be overstated. Traditional filtration systems often require extensive cleaning and maintenance, which can be labor-intensive and costly. In contrast, spiral filter belts are designed for easy cleaning, allowing operators to quickly remove accumulated debris without the need for specialized tools or extensive downtime. This ease of maintenance not only saves time but also reduces labor costs, making spiral filter belts a more economical choice in the long run.

Another significant advantage of spiral filter belts is their resistance to chemical degradation. Wastewater can contain a variety of corrosive substances that can compromise the integrity of standard filtration materials. However, spiral filter belts are often treated or constructed from materials that can withstand these harsh chemicals, ensuring that they maintain their structural integrity and performance over time. This chemical resistance further enhances their durability, making them a reliable option for facilities dealing with challenging wastewater compositions.

Furthermore, the design of spiral filter belts allows for better drainage and airflow, which are essential for preventing the buildup of sludge and other contaminants. This feature not only aids in maintaining the efficiency of the filtration process but also contributes to a cleaner operational environment. By minimizing the accumulation of waste materials, spiral filter belts help reduce the risk of system failures and the associated costs of repairs and replacements.

In conclusion, the durability and maintenance benefits of spiral filter belts make them an invaluable asset in wastewater filtration systems. Their robust construction, ease of cleaning, and resistance to chemical degradation ensure that they can withstand the rigors of wastewater treatment while providing consistent performance. As facilities continue to seek ways to optimize their operations and reduce costs, the adoption of spiral filter belts represents a forward-thinking approach to enhancing the efficiency and reliability of wastewater filtration processes. By investing in these advanced filtration solutions, operators can not only improve the quality of treated water but also achieve significant long-term savings in maintenance and operational costs.