How Spiral Filter Belts Optimize Paper Manufacturing Processes

Increased Efficiency in Dewatering Process

Paper manufacturing is a complex process that involves several stages, each of which plays a crucial role in producing high-quality paper products. One of the key stages in paper manufacturing is the dewatering process, where water is removed from the pulp to create a more solid material that can be further processed into paper. This process is essential for achieving the desired paper properties, such as strength, smoothness, and absorbency.

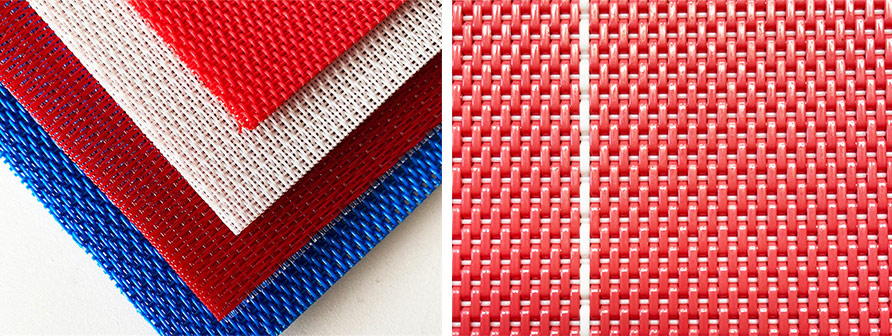

In recent years, spiral filter belts have emerged as a popular choice for optimizing the dewatering process in paper manufacturing. These belts are made from a continuous loop of polyester or polypropylene material, which is woven into a spiral pattern. The unique design of spiral filter belts allows for efficient water drainage and excellent air permeability, making them ideal for dewatering applications.

One of the key advantages of using spiral filter belts in the dewatering process is their ability to increase efficiency. The spiral pattern of the belts creates a large surface area for water drainage, allowing for faster and more effective dewatering of the pulp. This results in shorter processing times and higher throughput, ultimately leading to increased productivity and cost savings for paper manufacturers.

Furthermore, spiral filter belts are highly durable and resistant to wear and tear, making them a long-lasting solution for dewatering applications. Their robust construction ensures that they can withstand the harsh conditions of the paper manufacturing process, including high temperatures, chemicals, and mechanical stress. This durability not only reduces maintenance costs but also minimizes downtime, allowing for continuous operation and improved overall efficiency.

Another benefit of using spiral filter belts in the dewatering process is their versatility. These belts can be customized to meet the specific requirements of different paper grades and production processes. By adjusting the weave pattern, material composition, and other parameters, manufacturers can tailor spiral filter belts to achieve optimal dewatering performance for their unique applications.

In addition to their efficiency and durability, spiral filter belts also offer environmental benefits. By optimizing the dewatering process, these belts help reduce water consumption and energy usage in paper manufacturing. This not only lowers operating costs but also minimizes the environmental impact of paper production, making it a more sustainable and eco-friendly process.

Overall, spiral filter belts play a crucial role in optimizing the dewatering process in paper manufacturing. Their efficiency, durability, versatility, and environmental benefits make them a valuable investment for paper manufacturers looking to improve their production processes. By incorporating spiral filter belts into their operations, manufacturers can achieve higher productivity, lower costs, and a more sustainable approach to paper manufacturing.

Improved Paper Quality and Consistency

Paper manufacturing is a complex process that requires precision and efficiency to produce high-quality products. One key component of this process is the use of spiral filter belts, which play a crucial role in optimizing the manufacturing process and ensuring the quality and consistency of the final product.

Spiral filter belts are used in the paper manufacturing industry to filter out impurities and contaminants from the pulp mixture. These belts are made of high-quality materials such as polyester or polypropylene, which are durable and resistant to wear and tear. The spiral design of the belts allows for maximum filtration efficiency, ensuring that only clean pulp is used in the papermaking process.

By using spiral filter belts, paper manufacturers can improve the quality and consistency of their products. These belts help to remove unwanted particles and debris from the pulp mixture, resulting in a cleaner and more refined end product. This leads to a higher quality paper that is free from defects and imperfections, making it more desirable to consumers.

In addition to improving paper quality, spiral filter belts also help to optimize the manufacturing process itself. By filtering out impurities from the pulp mixture, these belts prevent clogs and blockages in the machinery, reducing downtime and increasing productivity. This results in a more efficient manufacturing process that is able to produce a higher volume of paper in a shorter amount of time.

Furthermore, spiral filter belts help to reduce waste in the paper manufacturing process. By filtering out contaminants from the pulp mixture, these belts ensure that only clean pulp is used in the production of paper. This leads to less waste and a more sustainable manufacturing process that is better for the environment.

Overall, spiral filter belts are an essential component of the paper manufacturing process. They help to improve paper quality and consistency, optimize the manufacturing process, and reduce waste. By using spiral filter belts, paper manufacturers can produce high-quality products more efficiently and sustainably, leading to greater success in the competitive paper industry.

In conclusion, spiral filter belts play a crucial role in optimizing paper manufacturing processes. These belts help to improve paper quality and consistency, optimize the manufacturing process, and reduce waste. By using spiral filter belts, paper manufacturers can produce high-quality products more efficiently and sustainably, leading to greater success in the competitive paper industry.

Cost Savings and Environmental Benefits

Spiral filter belts play a crucial role in optimizing paper manufacturing processes by improving efficiency, reducing costs, and minimizing environmental impact. These belts are used in various stages of the paper production process, from pulp washing to drying and finishing. By utilizing spiral filter belts, paper manufacturers can achieve significant cost savings and environmental benefits.

One of the key advantages of spiral filter belts is their ability to increase production efficiency. These belts are designed to provide a large surface area for filtration, allowing for faster and more effective dewatering of pulp and other materials. This results in shorter processing times and higher throughput, ultimately leading to increased productivity and reduced operating costs.

In addition to improving efficiency, spiral filter belts also help paper manufacturers save money by reducing maintenance and downtime. These belts are made from durable materials that are resistant to wear and tear, ensuring long-lasting performance with minimal need for repairs or replacements. By investing in high-quality spiral filter belts, paper manufacturers can avoid costly downtime and keep their production lines running smoothly.

Furthermore, spiral filter belts contribute to environmental sustainability by reducing water and energy consumption. The efficient dewatering capabilities of these belts result in lower water usage during the paper manufacturing process, helping to conserve this valuable resource. Additionally, the faster processing times enabled by spiral filter belts require less energy, further reducing the environmental impact of paper production.

By optimizing paper manufacturing processes with spiral filter belts, paper manufacturers can achieve significant cost savings and environmental benefits. These belts improve efficiency, reduce maintenance costs, and minimize water and energy consumption, making them a valuable investment for any paper production facility. With their durable construction and high-performance filtration capabilities, spiral filter belts are an essential component of modern paper manufacturing processes.

In conclusion, spiral filter belts play a crucial role in optimizing paper manufacturing processes by improving efficiency, reducing costs, and minimizing environmental impact. These belts provide a large surface area for filtration, leading to faster dewatering and increased productivity. By investing in high-quality spiral filter belts, paper manufacturers can save money on maintenance and downtime while also reducing water and energy consumption. Overall, spiral filter belts are a cost-effective and environmentally friendly solution for enhancing paper production processes.