How to Maintain Ultipleat High Flow Filters for Maximum Efficiency

Proper Installation Techniques for Ultipleat High Flow Filters

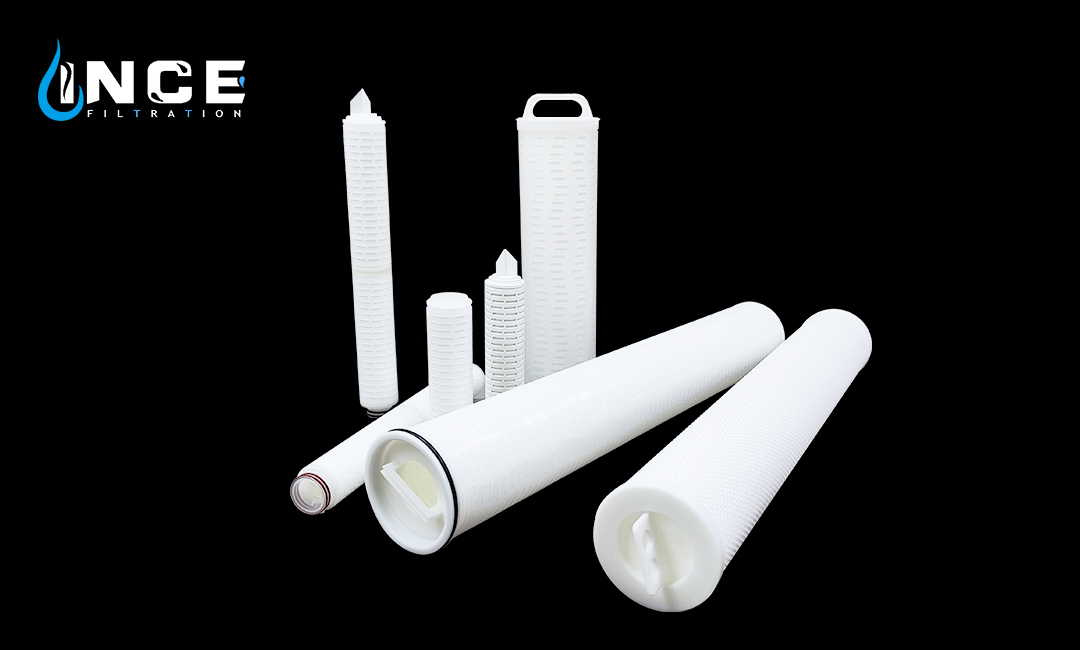

Ultipleat High Flow Filters are a critical component in many industrial processes, providing efficient filtration of liquids to ensure the quality and integrity of the final product. Proper installation techniques are essential to ensure that these filters operate at maximum efficiency and deliver the desired results. In this article, we will discuss some key steps to maintain Ultipleat High Flow Filters for optimal performance.

First and foremost, it is crucial to follow the manufacturer’s guidelines for installation. This includes ensuring that the filter is installed in the correct orientation and that all connections are secure. Improper installation can lead to leaks, bypassing of contaminants, and reduced filtration efficiency. By carefully following the manufacturer’s instructions, you can avoid these issues and ensure that your Ultipleat High Flow Filter performs as intended.

Another important aspect of maintaining Ultipleat High Flow Filters is regular inspection and monitoring. This includes checking for any signs of damage or wear, such as tears in the filter media or cracks in the housing. By regularly inspecting your filters, you can identify any potential issues early on and take corrective action before they escalate into more significant problems.

In addition to visual inspections, it is also essential to monitor the pressure drop across the filter. A sudden increase in pressure drop can indicate that the filter is becoming clogged and may need to be replaced. By monitoring the pressure drop regularly, you can proactively address any issues and prevent downtime or product quality issues.

Proper cleaning and maintenance are also crucial for maintaining Ultipleat High Flow Filters. Depending on the application, filters may need to be cleaned periodically to remove accumulated contaminants and restore filtration efficiency. This can typically be done by backwashing the filter or using a cleaning solution recommended by the manufacturer. By following the recommended cleaning procedures, you can extend the life of your filters and ensure consistent performance over time.

In some cases, it may be necessary to replace the filter media or other components of the filter. This is typically done when the filter has reached the end of its service life or when performance begins to decline despite regular maintenance. By replacing worn or damaged components promptly, you can avoid costly downtime and ensure that your filtration system continues to operate effectively.

Finally, it is essential to keep accurate records of maintenance activities and filter performance. This includes documenting when filters were installed, cleaned, or replaced, as well as any issues or concerns that arise during operation. By maintaining detailed records, you can track the performance of your filters over time and identify any trends or patterns that may indicate the need for adjustments or upgrades.

In conclusion, proper installation techniques and regular maintenance are essential for maintaining Ultipleat High Flow Filters for maximum efficiency. By following the manufacturer’s guidelines, monitoring filter performance, and conducting regular inspections and cleaning, you can ensure that your filters deliver consistent and reliable filtration results. By taking a proactive approach to filter maintenance, you can extend the life of your filters, minimize downtime, and ensure the quality and integrity of your final product.

Regular Cleaning and Maintenance Procedures for Ultipleat High Flow Filters

Ultipleat High Flow Filters are an essential component in many industrial processes, providing efficient filtration of liquids to ensure the quality and purity of the final product. To maintain the effectiveness of these filters and ensure maximum efficiency, regular cleaning and maintenance procedures are crucial. In this article, we will discuss the steps you can take to keep your Ultipleat High Flow Filters in optimal condition.

One of the most important aspects of maintaining Ultipleat High Flow Filters is regular cleaning. Over time, these filters can become clogged with debris and contaminants, reducing their effectiveness and potentially causing damage to the filter itself. To prevent this from happening, it is essential to clean the filters on a regular basis.

To clean Ultipleat High Flow Filters, start by removing them from the filtration system and inspecting them for any visible signs of damage or clogging. If you notice any issues, such as tears or holes in the filter material, it may be necessary to replace the filter entirely. Otherwise, proceed with the cleaning process.

To clean the filters, start by rinsing them with clean water to remove any surface debris. Next, soak the filters in a solution of warm water and a mild detergent, gently agitating them to help dislodge any trapped particles. After soaking, rinse the filters thoroughly with clean water to remove any remaining detergent residue.

In addition to regular cleaning, it is also important to perform routine maintenance on Ultipleat High Flow Filters to ensure their continued efficiency. This includes inspecting the filters for any signs of wear or damage, such as tears, holes, or disintegration of the filter material. If any issues are found, it is important to address them promptly to prevent further damage to the filter.

Another important aspect of maintaining Ultipleat High Flow Filters is ensuring that they are installed correctly in the filtration system. Improper installation can lead to leaks, reduced filtration efficiency, and potential damage to the filters themselves. To prevent these issues, carefully follow the manufacturer’s instructions for installing the filters and ensure that they are securely in place before operating the filtration system.

In addition to regular cleaning and maintenance, it is also important to monitor the performance of Ultipleat High Flow Filters on an ongoing basis. This includes regularly checking the pressure drop across the filters, as an increase in pressure drop can indicate that the filters are becoming clogged and may need to be cleaned or replaced. Monitoring the pressure drop can help you identify potential issues before they become more serious and costly to address.

In conclusion, maintaining Ultipleat High Flow Filters is essential for ensuring their continued efficiency and effectiveness in industrial filtration processes. By following the steps outlined in this article, including regular cleaning, routine maintenance, proper installation, and ongoing monitoring of filter performance, you can help maximize the lifespan and efficiency of your Ultipleat High Flow Filters. By taking these proactive measures, you can ensure that your filtration system operates at peak performance and produces high-quality, pure products.

Monitoring Pressure Drop and Flow Rates in Ultipleat High Flow Filters

Ultipleat High Flow Filters are a critical component in many industrial processes, providing efficient filtration of liquids to ensure the quality and integrity of the final product. To maintain the maximum efficiency of these filters, it is essential to monitor pressure drop and flow rates regularly.

Pressure drop is a key indicator of the condition of a filter. As a filter becomes clogged with particulates, the pressure drop across the filter increases. Monitoring pressure drop allows operators to determine when a filter needs to be replaced or cleaned to maintain optimal performance. Regular monitoring of pressure drop can also help identify potential issues with the filtration system, such as leaks or improper installation.

Flow rates are another important factor to consider when maintaining Ultipleat High Flow Filters. Proper flow rates are essential for efficient filtration and preventing damage to the filter media. Monitoring flow rates can help operators identify any fluctuations or deviations from the expected values, which may indicate a problem with the filter or the overall filtration system.

To monitor pressure drop and flow rates in Ultipleat High Flow Filters, operators can use a variety of tools and techniques. Pressure gauges can be installed on the inlet and outlet of the filter to measure the pressure drop across the filter. Regularly checking and recording these pressure readings can help operators track the condition of the filter over time.

Flow meters can also be used to monitor flow rates in Ultipleat High Flow Filters. By measuring the flow rate of the liquid entering and exiting the filter, operators can ensure that the filter is operating within the recommended flow range. Any significant deviations from the expected flow rates may indicate a problem with the filter or the filtration system that needs to be addressed.

In addition to monitoring pressure drop and flow rates, operators should also perform regular visual inspections of Ultipleat High Flow Filters. Inspecting the filter media for signs of damage or clogging can help identify issues before they impact the efficiency of the filter. Cleaning or replacing the filter media as needed can help maintain the performance of the filter and extend its lifespan.

Regular maintenance and monitoring of Ultipleat High Flow Filters are essential for ensuring maximum efficiency and performance. By monitoring pressure drop and flow rates, as well as performing visual inspections and cleaning or replacing filter media as needed, operators can keep their filters operating at peak performance. This not only helps to ensure the quality of the final product but also reduces downtime and maintenance costs associated with filter replacement. Ultimately, proper maintenance of Ultipleat High Flow Filters is essential for the success of any industrial filtration system.

Replacing Filter Elements in Ultipleat High Flow Filters as Needed

Ultipleat High Flow Filters are a critical component in many industrial processes, providing efficient filtration of liquids to ensure the quality and integrity of the final product. To maintain the effectiveness of these filters, it is essential to replace the filter elements as needed. In this article, we will discuss the importance of replacing filter elements in Ultipleat High Flow Filters and provide some tips on how to do so effectively.

One of the key reasons for replacing filter elements in Ultipleat High Flow Filters is to ensure maximum filtration efficiency. Over time, filter elements can become clogged with contaminants, reducing their ability to effectively remove particles from the liquid being filtered. This can lead to decreased filtration performance and potentially compromise the quality of the final product. By replacing filter elements as needed, you can ensure that your Ultipleat High Flow Filters continue to operate at peak efficiency.

Another reason to replace filter elements in Ultipleat High Flow Filters is to prevent damage to the filter housing. When filter elements become clogged, the pressure within the filter housing can increase, putting strain on the housing and potentially causing leaks or other damage. By replacing filter elements before they become too clogged, you can help prevent costly repairs and downtime.

So, how do you know when it’s time to replace the filter elements in your Ultipleat High Flow Filters? One common indicator is a decrease in flow rate. If you notice that the flow rate through the filter has slowed down significantly, it may be time to replace the filter elements. Additionally, if you observe a decrease in the quality of the filtered liquid or notice an increase in contaminants in the final product, this could also be a sign that the filter elements need to be replaced.

When replacing filter elements in Ultipleat High Flow Filters, it is important to follow the manufacturer’s guidelines for proper installation. This may include ensuring that the filter elements are installed in the correct orientation and that all seals and gaskets are properly in place. Failure to follow these guidelines could result in leaks or other issues that could compromise the effectiveness of the filter.

Additionally, it is important to use high-quality replacement filter elements that are designed specifically for use in Ultipleat High Flow Filters. Using subpar or incompatible filter elements could lead to decreased filtration efficiency and potentially damage the filter housing. Be sure to purchase replacement filter elements from a reputable supplier to ensure that you are getting the right product for your Ultipleat High Flow Filters.

In conclusion, replacing filter elements in Ultipleat High Flow Filters is essential for maintaining maximum filtration efficiency and preventing damage to the filter housing. By monitoring the flow rate and quality of the filtered liquid, you can determine when it is time to replace the filter elements. When replacing filter elements, be sure to follow the manufacturer’s guidelines for proper installation and use high-quality replacement filter elements. By taking these steps, you can ensure that your Ultipleat High Flow Filters continue to operate at peak efficiency and provide reliable filtration for your industrial processes.