Industrial Applications of High Flow Pleated Filters You Should Know

Benefits of Using High Flow Pleated Filters in Industrial Applications

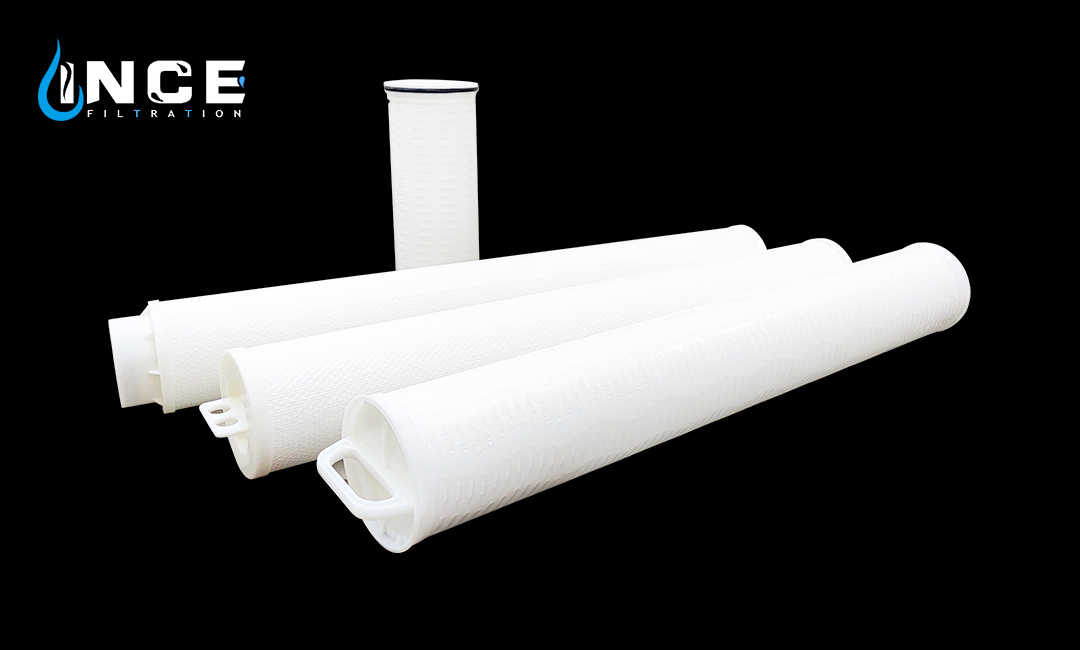

High flow pleated filters are an essential component in many industrial applications, providing a cost-effective and efficient solution for filtration needs. These filters are designed to handle high flow rates while maintaining a high level of filtration efficiency, making them ideal for a wide range of industries. In this article, we will explore the benefits of using high flow pleated filters in industrial applications.

One of the key benefits of high flow pleated filters is their ability to handle high flow rates. These filters are designed to accommodate a large volume of fluid while maintaining a high level of filtration efficiency. This makes them ideal for applications where a high flow rate is required, such as in the oil and gas industry, chemical processing, and water treatment plants.

In addition to their high flow capacity, high flow pleated filters also offer a high level of filtration efficiency. These filters are designed to remove contaminants from the fluid stream, ensuring that the end product meets the required quality standards. This is essential in industries where product quality is paramount, such as in the pharmaceutical and food and beverage industries.

Another benefit of using high flow pleated filters in industrial applications is their cost-effectiveness. These filters are designed to provide a long service life, reducing the need for frequent filter replacements. This not only saves money on filter replacement costs but also reduces downtime and maintenance costs associated with filter changes.

Furthermore, high flow pleated filters are easy to install and maintain, making them a convenient option for industrial applications. These filters can be easily replaced when needed, minimizing downtime and ensuring that production processes run smoothly. This is essential in industries where any disruption to production can result in significant financial losses.

High flow pleated filters are also versatile and can be customized to meet specific filtration requirements. These filters can be designed to remove a wide range of contaminants, including particles, bacteria, and other impurities. This makes them suitable for a variety of industrial applications, from water treatment to chemical processing.

Overall, high flow pleated filters offer a range of benefits for industrial applications, including high flow capacity, filtration efficiency, cost-effectiveness, ease of installation and maintenance, and versatility. These filters are an essential component in many industries, providing a reliable and efficient solution for filtration needs.

In conclusion, high flow pleated filters are a valuable asset in industrial applications, offering a range of benefits that make them an ideal choice for a wide range of industries. Whether you are in the oil and gas industry, chemical processing, water treatment, or any other industry that requires high flow filtration, high flow pleated filters are a cost-effective and efficient solution that can help improve product quality and streamline production processes.

Common Types of Contaminants Filtered by High Flow Pleated Filters

High flow pleated filters are an essential component in many industrial applications, providing efficient filtration of various contaminants to ensure the smooth operation of equipment and processes. These filters are designed to handle high flow rates while maintaining a high level of filtration efficiency, making them ideal for a wide range of applications. In this article, we will explore some common types of contaminants that high flow pleated filters can effectively remove, highlighting their importance in industrial settings.

One of the most common types of contaminants that high flow pleated filters are designed to remove is particulate matter. Particulate matter can come in various forms, including dust, dirt, and debris, and can be present in both liquid and gas streams. High flow pleated filters are capable of capturing these particles, preventing them from entering sensitive equipment or processes where they can cause damage or reduce efficiency.

Another common type of contaminant that high flow pleated filters can effectively remove is sediment. Sediment can accumulate in pipelines, tanks, and other equipment, leading to blockages and reduced flow rates. High flow pleated filters are designed to trap sediment particles, preventing them from causing issues within the system and ensuring that equipment operates smoothly.

In addition to particulate matter and sediment, high flow pleated filters are also effective at removing contaminants such as oils and greases. These substances can be present in industrial processes and can cause issues such as equipment wear and reduced efficiency. High flow pleated filters are designed to capture oils and greases, ensuring that they are not able to contaminate equipment or processes.

High flow pleated filters are also capable of removing microbial contaminants, such as bacteria and viruses, from liquid streams. In industries where maintaining a high level of cleanliness is essential, such as food and beverage production or pharmaceutical manufacturing, high flow pleated filters play a crucial role in ensuring that products meet quality standards and are safe for consumption.

Overall, high flow pleated filters are versatile and effective tools for removing a wide range of contaminants from industrial processes. Their ability to handle high flow rates while maintaining a high level of filtration efficiency makes them an ideal choice for many applications. Whether it is removing particulate matter, sediment, oils and greases, or microbial contaminants, high flow pleated filters are essential for ensuring the smooth operation of equipment and processes in industrial settings.

In conclusion, high flow pleated filters are an indispensable component in many industrial applications, providing efficient filtration of various contaminants to ensure the smooth operation of equipment and processes. By effectively removing contaminants such as particulate matter, sediment, oils and greases, and microbial contaminants, high flow pleated filters play a crucial role in maintaining the cleanliness and efficiency of industrial processes. Their versatility and effectiveness make them a valuable asset in a wide range of industries, where maintaining high levels of filtration efficiency is essential for ensuring product quality and operational efficiency.

How High Flow Pleated Filters Improve Efficiency and Performance in Industrial Processes

High flow pleated filters are an essential component in many industrial processes, providing a cost-effective and efficient solution for removing contaminants from liquids and gases. These filters are designed to handle high flow rates while maintaining a low pressure drop, making them ideal for applications where a large volume of fluid needs to be filtered quickly and effectively.

One of the key benefits of high flow pleated filters is their ability to improve efficiency in industrial processes. By capturing contaminants such as dirt, debris, and particles, these filters help to prevent equipment damage and reduce downtime. This is particularly important in industries such as manufacturing, oil and gas, and food and beverage, where even small amounts of contamination can have a significant impact on production.

In addition to improving efficiency, high flow pleated filters also enhance performance in industrial processes. By ensuring that only clean fluid passes through the system, these filters help to maintain the quality and consistency of the end product. This is crucial in industries where product purity is essential, such as pharmaceuticals and electronics manufacturing.

Furthermore, high flow pleated filters are designed to be durable and long-lasting, making them a reliable choice for industrial applications. With proper maintenance and care, these filters can provide consistent performance over an extended period of time, reducing the need for frequent replacements and saving on costs.

Another advantage of high flow pleated filters is their versatility. These filters can be customized to meet the specific requirements of different industrial processes, including varying flow rates, pressure levels, and contaminant types. This flexibility makes high flow pleated filters suitable for a wide range of applications, from water treatment to chemical processing.

Moreover, high flow pleated filters are easy to install and replace, minimizing downtime and ensuring that production can continue uninterrupted. This is particularly important in industries where any disruption to operations can result in significant financial losses.

Overall, high flow pleated filters offer a reliable and efficient solution for improving efficiency and performance in industrial processes. With their ability to handle high flow rates, capture contaminants, and enhance product quality, these filters are a valuable asset for any industrial operation.

In conclusion, high flow pleated filters play a crucial role in industrial applications, providing a cost-effective and efficient solution for removing contaminants from liquids and gases. By improving efficiency, enhancing performance, and offering versatility, these filters help to ensure the smooth operation of industrial processes. With their durability, reliability, and ease of installation, high flow pleated filters are a valuable investment for any industrial operation looking to optimize its filtration system.

Case Studies Highlighting Successful Implementation of High Flow Pleated Filters in Various Industries

High flow pleated filters are a crucial component in many industrial applications, providing efficient filtration of liquids and gases to ensure the smooth operation of equipment and processes. These filters are designed to handle high flow rates while maintaining excellent filtration efficiency, making them ideal for a wide range of industries. In this article, we will explore some case studies highlighting the successful implementation of high flow pleated filters in various industrial settings.

One industry that has benefited greatly from the use of high flow pleated filters is the oil and gas sector. In this industry, the filtration of fluids is essential to prevent equipment damage and ensure the quality of the final product. High flow pleated filters have been successfully implemented in oil and gas processing plants to remove contaminants such as dirt, rust, and other particles from the fluid stream. By using high flow pleated filters, companies in the oil and gas industry have been able to improve the efficiency of their operations and reduce maintenance costs.

Another industry where high flow pleated filters have proven to be highly effective is the pharmaceutical industry. In pharmaceutical manufacturing, the filtration of liquids is critical to ensure the purity and safety of the final product. High flow pleated filters are used in pharmaceutical plants to remove bacteria, viruses, and other contaminants from the process stream. By implementing high flow pleated filters, pharmaceutical companies have been able to meet stringent regulatory requirements and produce high-quality products for their customers.

The food and beverage industry is another sector that has seen significant benefits from the use of high flow pleated filters. In food and beverage processing plants, the filtration of liquids is essential to ensure the safety and quality of the final product. High flow pleated filters are used in these plants to remove impurities such as particles, bacteria, and other contaminants from the process stream. By using high flow pleated filters, companies in the food and beverage industry have been able to improve product quality, reduce waste, and increase production efficiency.

In the automotive industry, high flow pleated filters are used in a variety of applications, including paint booths, parts cleaning systems, and coolant filtration systems. These filters are designed to handle high flow rates and remove contaminants such as oil, grease, and dirt from the process stream. By using high flow pleated filters, automotive manufacturers have been able to improve the quality of their products, reduce maintenance costs, and increase production efficiency.

Overall, high flow pleated filters have proven to be a valuable asset in a wide range of industrial applications. By providing efficient filtration of liquids and gases, these filters help companies improve product quality, reduce maintenance costs, and increase production efficiency. Whether in the oil and gas, pharmaceutical, food and beverage, or automotive industry, high flow pleated filters play a crucial role in ensuring the smooth operation of equipment and processes. As technology continues to advance, we can expect to see even more innovative uses of high flow pleated filters in various industries in the future.