Industrial Spiral Press Fabric: A Game-Changer for Filtration Processes

Benefits of Using Industrial Spiral Press Fabric in Filtration Processes

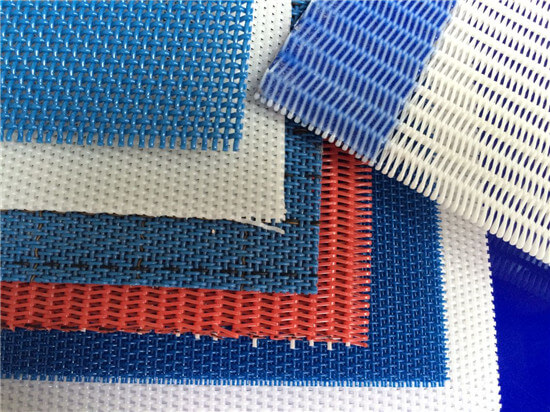

Industrial spiral press fabric is a revolutionary material that has transformed the way filtration processes are carried out in various industries. This innovative fabric is made from high-quality materials that are designed to withstand the harsh conditions of industrial filtration. Its unique spiral design allows for maximum filtration efficiency, making it a game-changer for businesses looking to improve their filtration processes.

One of the key benefits of using industrial spiral press fabric is its superior filtration capabilities. The spiral design of the fabric allows for a larger surface area, which means more particles can be captured and removed from the liquid or gas being filtered. This results in cleaner, purer products and a more efficient filtration process overall.

In addition to its superior filtration capabilities, industrial spiral press fabric is also highly durable and long-lasting. Unlike traditional filter materials that can break down over time, spiral press fabric is designed to withstand the rigors of industrial use. This means businesses can rely on this fabric to provide consistent and reliable filtration performance for years to come.

Another benefit of using industrial spiral press fabric is its versatility. This fabric can be used in a wide range of filtration applications, from wastewater treatment to food and beverage processing. Its flexibility and adaptability make it an ideal choice for businesses looking to streamline their filtration processes and improve overall efficiency.

Furthermore, industrial spiral press fabric is easy to clean and maintain, reducing downtime and ensuring continuous operation. This fabric can be easily removed, cleaned, and reinstalled, making it a cost-effective and efficient solution for businesses looking to optimize their filtration processes.

In conclusion, industrial spiral press fabric is a game-changer for filtration processes in various industries. Its superior filtration capabilities, durability, versatility, and ease of maintenance make it an ideal choice for businesses looking to improve their filtration processes and achieve better results. By investing in industrial spiral press fabric, businesses can enhance their operations, increase productivity, and ensure the highest quality of their products.

How Industrial Spiral Press Fabric Improves Efficiency in Filtration Processes

Industrial spiral press fabric is a crucial component in the filtration processes of various industries. This innovative fabric has revolutionized the way filtration is done, offering improved efficiency and effectiveness in separating solids from liquids. In this article, we will explore how industrial spiral press fabric has become a game-changer in filtration processes.

One of the key advantages of industrial spiral press fabric is its ability to handle high volumes of liquid and solid materials. The unique design of the fabric allows for maximum filtration surface area, ensuring that the filtration process is thorough and efficient. This means that industries can process larger quantities of materials in a shorter amount of time, leading to increased productivity and cost savings.

Furthermore, industrial spiral press fabric is highly durable and long-lasting, making it a cost-effective solution for filtration processes. Unlike traditional filter media that need frequent replacement, spiral press fabric can withstand the rigors of industrial use without losing its effectiveness. This means that industries can save money on maintenance and replacement costs, while also reducing downtime and increasing overall efficiency.

Another benefit of industrial spiral press fabric is its versatility in handling different types of materials. Whether it is sludge, pulp, or wastewater, this fabric can effectively separate solids from liquids, resulting in cleaner and clearer filtrate. This versatility makes industrial spiral press fabric ideal for a wide range of industries, including mining, food and beverage, and wastewater treatment.

In addition to its efficiency and durability, industrial spiral press fabric is also easy to clean and maintain. The smooth surface of the fabric prevents clogging and buildup, ensuring that the filtration process remains consistent and reliable. This ease of maintenance not only saves time and effort but also ensures that the fabric lasts longer and performs at its best.

Moreover, industrial spiral press fabric is environmentally friendly, as it reduces the need for harsh chemicals and additives in the filtration process. By using a mechanical separation method, this fabric minimizes the environmental impact of filtration processes, making it a sustainable choice for industries looking to reduce their carbon footprint.

Overall, industrial spiral press fabric has become a game-changer in filtration processes, offering improved efficiency, durability, versatility, and sustainability. Its ability to handle high volumes of materials, its long-lasting performance, and its ease of maintenance make it an ideal choice for industries looking to optimize their filtration processes.

In conclusion, industrial spiral press fabric is a valuable asset for industries seeking to improve their filtration processes. With its numerous benefits and advantages, this fabric has proven to be a game-changer in the field of filtration, offering a cost-effective and sustainable solution for separating solids from liquids. Industries that invest in industrial spiral press fabric can expect to see increased efficiency, productivity, and cost savings in their filtration processes.

Case Studies Highlighting the Success of Industrial Spiral Press Fabric in Filtration Applications

Industrial spiral press fabric has revolutionized the filtration industry with its superior performance and efficiency. This innovative fabric is designed to withstand the rigorous demands of industrial filtration processes, making it a game-changer for businesses looking to improve their filtration operations.

One of the key advantages of industrial spiral press fabric is its durability. Made from high-quality materials, this fabric is able to withstand high temperatures, corrosive chemicals, and heavy loads without losing its effectiveness. This durability ensures that the fabric can be used in a wide range of filtration applications, from wastewater treatment to food processing.

In addition to its durability, industrial spiral press fabric is also highly efficient. The unique spiral design of the fabric allows for maximum filtration surface area, ensuring that even the smallest particles are captured and removed from the filtrate. This increased efficiency results in cleaner filtrate and reduced operating costs for businesses.

To illustrate the success of industrial spiral press fabric in filtration applications, let’s take a look at a few case studies. In one case study, a wastewater treatment plant was struggling to remove fine particles from their filtrate. After switching to industrial spiral press fabric, the plant saw a significant improvement in their filtration process. The fabric’s increased surface area allowed for better particle capture, resulting in cleaner filtrate and reduced maintenance costs.

Another case study involves a food processing plant that was experiencing clogging issues with their filtration system. By switching to industrial spiral press fabric, the plant was able to increase their filtration efficiency and reduce downtime caused by clogs. The fabric’s durable construction and high filtration capacity made it the perfect solution for the plant’s filtration needs.

Overall, industrial spiral press fabric has proven to be a game-changer for businesses looking to improve their filtration processes. Its durability, efficiency, and versatility make it an ideal choice for a wide range of applications. Whether you’re in the wastewater treatment, food processing, or chemical industry, industrial spiral press fabric can help you achieve cleaner filtrate and lower operating costs.

In conclusion, industrial spiral press fabric is a valuable tool for businesses looking to enhance their filtration processes. Its durability, efficiency, and versatility make it a top choice for a wide range of applications. By investing in industrial spiral press fabric, businesses can improve their filtration operations and achieve cleaner filtrate with reduced maintenance costs. If you’re looking to take your filtration process to the next level, consider making the switch to industrial spiral press fabric today.