Industry Applications of Pall’s Ultipleat High Flow Filters

Benefits of Using Pall’s Ultipleat High Flow Filters in Oil and Gas Industry

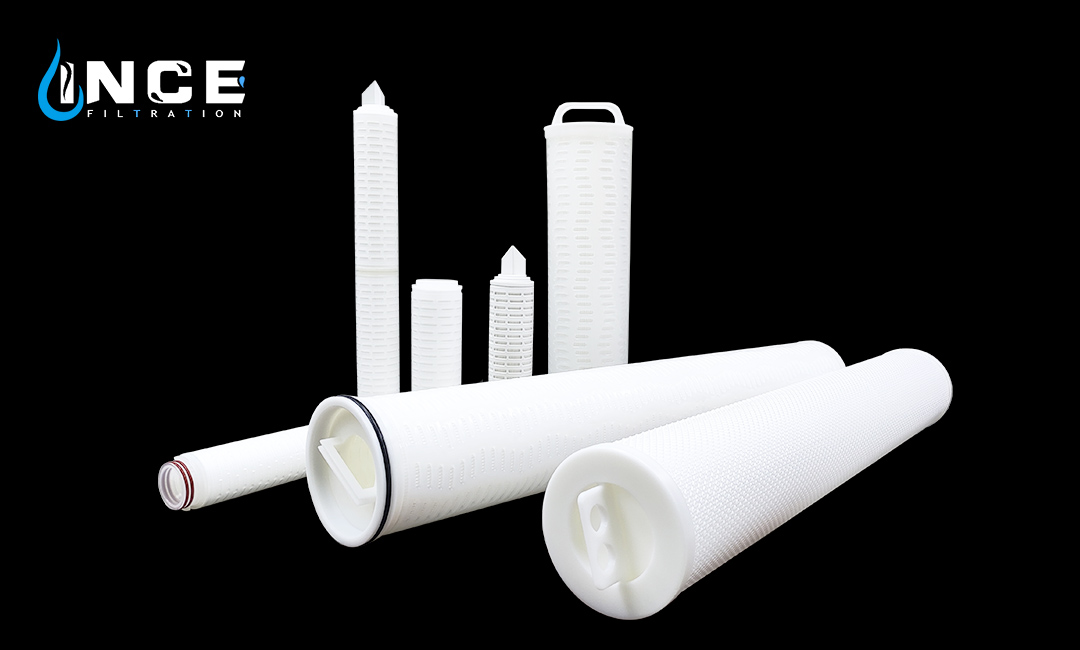

Pall’s Ultipleat High Flow Filters have become a popular choice in the oil and gas industry due to their efficiency and effectiveness in filtering out contaminants. These filters are designed to handle high flow rates while maintaining a high level of filtration efficiency, making them ideal for a wide range of applications in the industry.

One of the key benefits of using Pall’s Ultipleat High Flow Filters in the oil and gas industry is their ability to remove contaminants such as dirt, sand, and other particles from the fluid stream. This is crucial in maintaining the integrity of equipment and ensuring the smooth operation of processes. By using these filters, companies can prevent damage to pumps, valves, and other components, ultimately reducing maintenance costs and downtime.

In addition to their superior filtration capabilities, Pall’s Ultipleat High Flow Filters are also known for their long service life. These filters are designed to withstand high flow rates and high levels of contamination without compromising their performance. This means that companies can rely on these filters to provide consistent and reliable filtration over an extended period, reducing the need for frequent filter replacements and maintenance.

Another advantage of using Pall’s Ultipleat High Flow Filters in the oil and gas industry is their compact design. These filters have a smaller footprint compared to traditional filtration systems, making them ideal for applications where space is limited. This allows companies to optimize their use of available space and streamline their operations without sacrificing filtration efficiency.

Furthermore, Pall’s Ultipleat High Flow Filters are easy to install and maintain, making them a cost-effective solution for companies in the oil and gas industry. These filters can be quickly and easily replaced when needed, minimizing downtime and ensuring continuous operation. Additionally, their robust construction and high-quality materials make them resistant to corrosion and wear, further extending their service life and reducing overall operating costs.

Overall, Pall’s Ultipleat High Flow Filters offer a range of benefits for companies in the oil and gas industry. From their superior filtration capabilities to their long service life and compact design, these filters provide a reliable and cost-effective solution for a variety of applications. By choosing Pall’s Ultipleat High Flow Filters, companies can improve the efficiency and reliability of their operations while reducing maintenance costs and downtime.

How Pall’s Ultipleat High Flow Filters Improve Efficiency in Chemical Processing Plants

Pall’s Ultipleat High Flow Filters are a critical component in chemical processing plants, providing a reliable and efficient solution for removing contaminants and ensuring product quality. These filters are designed to handle high flow rates and large volumes of fluid, making them ideal for industrial applications where efficiency and performance are paramount.

One of the key benefits of Pall’s Ultipleat High Flow Filters is their ability to improve overall system efficiency. By capturing contaminants and particulates from the fluid stream, these filters help prevent equipment damage and reduce downtime. This not only extends the life of the equipment but also minimizes maintenance costs and improves overall plant productivity.

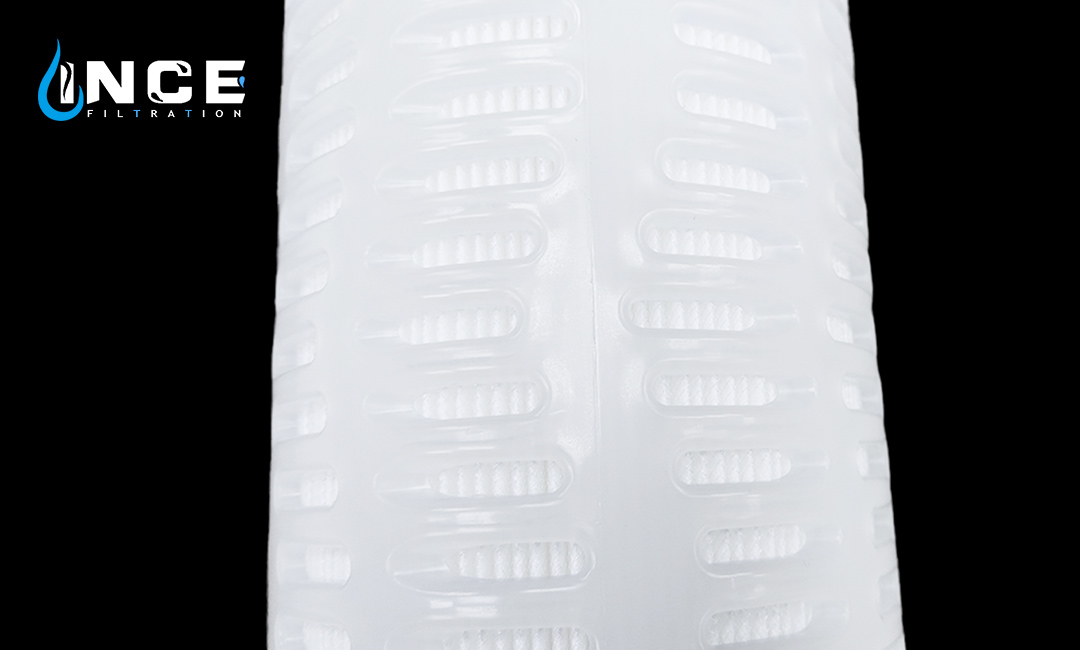

In addition to improving system efficiency, Pall’s Ultipleat High Flow Filters also offer superior filtration performance. These filters are designed to provide high dirt-holding capacity and low pressure drop, ensuring optimal filtration efficiency and consistent product quality. This is particularly important in chemical processing plants where product purity is critical to meeting industry standards and customer requirements.

Furthermore, Pall’s Ultipleat High Flow Filters are versatile and can be customized to meet specific application requirements. Whether it’s removing particulates, reducing contaminants, or improving product clarity, these filters can be tailored to address a wide range of filtration needs. This flexibility allows chemical processing plants to optimize their filtration systems and achieve the desired level of product quality.

Another advantage of Pall’s Ultipleat High Flow Filters is their ease of installation and maintenance. These filters are designed for quick and simple replacement, minimizing downtime and reducing labor costs. With their durable construction and long service life, Pall’s Ultipleat High Flow Filters offer a cost-effective solution for chemical processing plants looking to improve filtration efficiency and reduce operational expenses.

Moreover, Pall’s Ultipleat High Flow Filters are designed to meet the stringent requirements of the chemical processing industry. These filters are constructed from high-quality materials that are compatible with a wide range of chemicals and fluids, ensuring reliable performance in harsh operating conditions. This makes Pall’s Ultipleat High Flow Filters a trusted choice for chemical processing plants seeking a dependable and efficient filtration solution.

In conclusion, Pall’s Ultipleat High Flow Filters are a valuable asset for chemical processing plants looking to improve efficiency and enhance product quality. With their superior filtration performance, versatility, and ease of installation, these filters offer a reliable and cost-effective solution for a wide range of industrial applications. By investing in Pall’s Ultipleat High Flow Filters, chemical processing plants can optimize their filtration systems, reduce maintenance costs, and achieve consistent product quality, ultimately improving overall plant performance and profitability.

Case Studies Demonstrating the Effectiveness of Pall’s Ultipleat High Flow Filters in Water Treatment Facilities

Pall’s Ultipleat High Flow Filters have become a popular choice for water treatment facilities across various industries due to their efficiency and effectiveness in removing contaminants from water. These filters are designed to handle high flow rates while maintaining a high level of filtration efficiency, making them ideal for industrial applications where large volumes of water need to be treated quickly and effectively.

One industry where Pall’s Ultipleat High Flow Filters have proven to be particularly effective is the food and beverage industry. In this industry, water quality is of utmost importance as it directly impacts the quality and safety of the final product. Contaminants such as bacteria, viruses, and other impurities can pose a serious threat to the health of consumers if not properly removed from the water used in the production process.

By using Pall’s Ultipleat High Flow Filters, food and beverage companies can ensure that their water meets the highest standards of purity and safety. These filters are capable of removing a wide range of contaminants, including bacteria and viruses, ensuring that the water used in the production process is free from harmful impurities. This not only helps to protect consumers from potential health risks but also ensures that the final product meets regulatory requirements for water quality.

Another industry where Pall’s Ultipleat High Flow Filters have been widely adopted is the pharmaceutical industry. In this industry, water plays a critical role in the production of pharmaceutical products, as it is used in various processes such as cleaning, sterilization, and formulation. Any impurities in the water can compromise the quality and safety of the final product, making it essential to use high-quality filtration systems to ensure that the water meets the required standards.

Pall’s Ultipleat High Flow Filters are well-suited for use in pharmaceutical applications due to their high filtration efficiency and capacity to handle large flow rates. These filters can effectively remove contaminants such as bacteria, endotoxins, and particulates, ensuring that the water used in pharmaceutical production is of the highest quality. By using Pall’s Ultipleat High Flow Filters, pharmaceutical companies can maintain the integrity of their products and comply with regulatory requirements for water quality.

In addition to the food and beverage and pharmaceutical industries, Pall’s Ultipleat High Flow Filters have also found applications in other industries such as power generation, chemical processing, and wastewater treatment. In these industries, water quality is critical for ensuring the efficient operation of equipment and processes, as well as for protecting the environment from harmful pollutants.

By using Pall’s Ultipleat High Flow Filters, companies in these industries can effectively remove contaminants from water, ensuring that it meets the required standards for purity and safety. These filters are designed to handle the high flow rates and large volumes of water typically found in industrial applications, making them a reliable and cost-effective solution for water treatment.

Overall, Pall’s Ultipleat High Flow Filters have proven to be a versatile and effective solution for a wide range of industrial applications where water quality is a priority. By using these filters, companies can ensure that their water meets the highest standards of purity and safety, protecting both their products and the environment from potential harm. With their high filtration efficiency and capacity to handle large flow rates, Pall’s Ultipleat High Flow Filters are a valuable asset for any water treatment facility looking to improve the quality of their water.