Innovative Technologies in Hi Flow Filter Cartridges

Benefits of Using Hi Flow Filter Cartridges in Industrial Applications

In today’s rapidly evolving industrial landscape, the need for efficient filtration solutions has never been greater. As industries continue to grow and expand, the demand for high-performance filtration systems that can handle large volumes of fluid while maintaining optimal filtration efficiency has become a top priority. This is where hi flow filter cartridges come into play, offering a range of benefits that make them an ideal choice for industrial applications.

One of the key advantages of hi flow filter cartridges is their ability to handle high flow rates without compromising on filtration efficiency. Traditional filter cartridges often struggle to keep up with the demands of high-flow applications, leading to decreased filtration performance and increased maintenance costs. Hi flow filter cartridges, on the other hand, are specifically designed to handle high flow rates, ensuring that fluid is filtered effectively and efficiently without any drop in performance.

Another benefit of hi flow filter cartridges is their compact size and easy installation. Unlike larger filtration systems that require extensive space and complex installation procedures, hi flow filter cartridges can be easily integrated into existing systems with minimal disruption. This makes them a cost-effective and convenient solution for industries looking to upgrade their filtration systems without the need for extensive modifications.

In addition to their high flow capacity and easy installation, hi flow filter cartridges also offer superior filtration performance. These cartridges are designed to remove a wide range of contaminants from fluid streams, including particles, debris, and other impurities that can compromise the quality of the end product. By using hi flow filter cartridges, industries can ensure that their processes run smoothly and efficiently, with minimal downtime and maintenance requirements.

Furthermore, hi flow filter cartridges are highly versatile and can be customized to meet the specific needs of different industries and applications. Whether it’s filtering water, chemicals, or other fluids, hi flow filter cartridges can be tailored to provide the optimal filtration solution for any given situation. This level of customization ensures that industries can achieve the highest level of filtration performance while maximizing efficiency and productivity.

Overall, the benefits of using hi flow filter cartridges in industrial applications are clear. From their high flow capacity and superior filtration performance to their compact size and easy installation, these cartridges offer a range of advantages that make them an ideal choice for industries looking to improve their filtration systems. By investing in hi flow filter cartridges, industries can ensure that their processes run smoothly and efficiently, with minimal downtime and maintenance costs. In an increasingly competitive industrial landscape, hi flow filter cartridges are a valuable asset that can help industries stay ahead of the curve and achieve their filtration goals with ease.

How Innovative Technologies Improve Efficiency and Performance of Hi Flow Filter Cartridges

Innovative technologies have revolutionized the way hi flow filter cartridges operate, significantly improving their efficiency and performance. These advancements have allowed for better filtration, increased durability, and enhanced overall functionality. By incorporating cutting-edge technologies into hi flow filter cartridges, manufacturers have been able to meet the growing demands of various industries and applications.

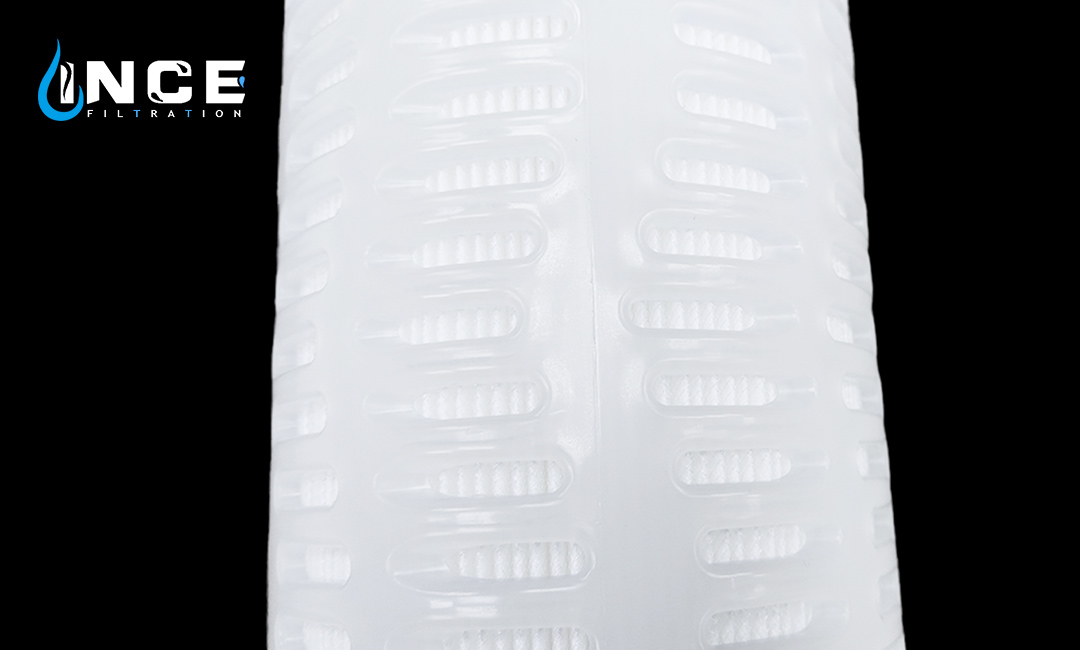

One of the key innovations in hi flow filter cartridges is the use of advanced materials such as synthetic fibers and membranes. These materials are designed to provide superior filtration capabilities, capturing even the smallest particles and contaminants. By using these materials, hi flow filter cartridges can achieve higher flow rates while maintaining excellent filtration efficiency. This results in cleaner, purer fluids and gases, making them ideal for a wide range of industrial processes.

Another important technological advancement in hi flow filter cartridges is the development of self-cleaning mechanisms. These mechanisms are designed to automatically remove accumulated debris and contaminants from the filter media, ensuring continuous and efficient filtration. By incorporating self-cleaning features, hi flow filter cartridges can operate for longer periods without the need for manual maintenance, reducing downtime and increasing productivity.

Furthermore, the integration of smart technologies has also played a significant role in improving the efficiency and performance of hi flow filter cartridges. Smart sensors and monitoring systems can provide real-time data on filter performance, allowing for proactive maintenance and troubleshooting. By leveraging these technologies, operators can optimize filter performance, extend filter life, and reduce operating costs.

In addition to these advancements, the design of hi flow filter cartridges has also evolved to enhance their efficiency and performance. Innovative geometries and configurations have been developed to maximize filtration surface area and flow rates, improving overall filtration efficiency. By optimizing the design of hi flow filter cartridges, manufacturers can achieve higher levels of performance while reducing energy consumption and operational costs.

Overall, the integration of innovative technologies in hi flow filter cartridges has led to significant improvements in efficiency and performance. These advancements have enabled hi flow filter cartridges to meet the evolving needs of various industries, providing reliable and consistent filtration solutions. By incorporating advanced materials, self-cleaning mechanisms, smart technologies, and optimized designs, hi flow filter cartridges can deliver superior filtration performance, increased durability, and enhanced functionality.

As industries continue to demand higher levels of filtration efficiency and performance, the development of innovative technologies in hi flow filter cartridges will play a crucial role in meeting these requirements. By staying at the forefront of technological advancements, manufacturers can continue to push the boundaries of what is possible in filtration technology, providing customers with cutting-edge solutions that deliver exceptional results. With ongoing research and development, the future of hi flow filter cartridges looks promising, with even greater advancements on the horizon.

Comparison of Different Types of Hi Flow Filter Cartridges and Their Technological Advancements

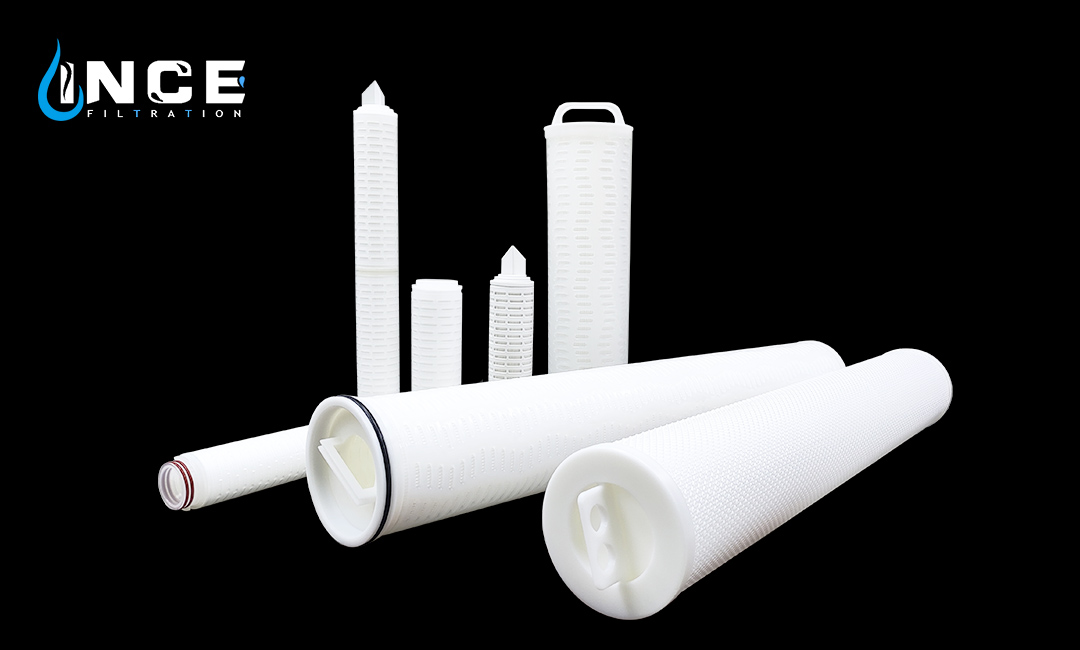

In the world of filtration, hi flow filter cartridges play a crucial role in removing impurities from liquids and gases. These cartridges are designed to handle high flow rates while maintaining efficiency in capturing particles of various sizes. Over the years, advancements in technology have led to the development of innovative hi flow filter cartridges that offer improved performance and durability.

One of the key technological advancements in hi flow filter cartridges is the use of pleated filter media. Pleated filter media provides a larger surface area for filtration, allowing for higher flow rates and better particle capture efficiency. This design also helps to extend the life of the filter cartridge, reducing the frequency of replacements and maintenance costs.

Another important innovation in hi flow filter cartridges is the incorporation of nanofiber technology. Nanofiber filter media consists of ultra-fine fibers that are electrostatically charged to attract and capture particles as small as 0.1 microns. This technology significantly improves the filtration efficiency of hi flow filter cartridges, making them ideal for applications where fine particle removal is critical.

In addition to pleated filter media and nanofiber technology, some hi flow filter cartridges are equipped with antimicrobial additives. These additives help to inhibit the growth of bacteria and other microorganisms on the filter media, ensuring that the filtered liquid or gas remains clean and free from contaminants. This feature is particularly important in industries such as food and beverage, pharmaceuticals, and healthcare, where maintaining a sterile environment is essential.

Furthermore, some hi flow filter cartridges are designed with self-cleaning mechanisms to prolong their lifespan and reduce maintenance requirements. These self-cleaning filters use backwashing or reverse flow techniques to dislodge trapped particles from the filter media, allowing for continuous operation without the need for frequent replacements or manual cleaning.

When comparing different types of hi flow filter cartridges, it is important to consider factors such as filtration efficiency, flow rate capacity, pressure drop, and compatibility with specific liquids or gases. Some hi flow filter cartridges are designed for general-purpose filtration, while others are tailored for specialized applications such as oil and gas, water treatment, or chemical processing.

In conclusion, innovative technologies have revolutionized the design and performance of hi flow filter cartridges, making them more efficient, durable, and versatile than ever before. Whether you are looking to improve the quality of your products, protect equipment from contamination, or comply with regulatory standards, investing in high-quality hi flow filter cartridges with advanced technological features is essential. By choosing the right filter cartridge for your specific needs, you can ensure optimal filtration performance and peace of mind knowing that your processes are running smoothly and efficiently.

Future Trends and Developments in Hi Flow Filter Cartridges with Innovative Technologies

In recent years, the filtration industry has seen significant advancements in technology, particularly in the development of hi flow filter cartridges. These innovative technologies have revolutionized the way we filter liquids and gases, providing more efficient and effective solutions for a wide range of industries. From improved filtration performance to enhanced durability and sustainability, the future of hi flow filter cartridges looks promising.

One of the key trends in hi flow filter cartridges is the use of advanced materials and coatings. Manufacturers are constantly exploring new materials that offer better filtration efficiency, longer lifespan, and resistance to harsh chemicals and high temperatures. For example, the use of nanofiber technology has been gaining popularity in recent years due to its ability to capture smaller particles and provide higher flow rates compared to traditional filter media.

Another important development in hi flow filter cartridges is the integration of smart technology. By incorporating sensors and monitoring systems into filter cartridges, manufacturers are able to provide real-time data on filter performance, pressure drop, and remaining lifespan. This allows for proactive maintenance and replacement, reducing downtime and optimizing filtration efficiency.

Furthermore, the rise of Industry 4.0 and the Internet of Things (IoT) has enabled remote monitoring and control of filter systems, allowing operators to access critical data and make informed decisions from anywhere in the world. This connectivity not only improves operational efficiency but also enables predictive maintenance, reducing the risk of unexpected filter failures and costly downtime.

In addition to advanced materials and smart technology, sustainability is also a key focus in the development of hi flow filter cartridges. Manufacturers are increasingly looking for ways to reduce the environmental impact of their products, from using recyclable materials to designing filters that require less energy and water for production. Some companies are even exploring the use of biodegradable filter media that can be safely disposed of after use.

Furthermore, the concept of circular economy is gaining traction in the filtration industry, with a focus on extending the lifespan of filter cartridges through refurbishment and recycling. By designing filters that are easy to disassemble and replace individual components, manufacturers can reduce waste and minimize the need for new filter production.

Overall, the future of hi flow filter cartridges is bright, with innovative technologies driving advancements in filtration performance, durability, and sustainability. As industries continue to demand higher efficiency and reliability from their filtration systems, manufacturers will need to stay ahead of the curve by investing in research and development to bring cutting-edge solutions to market.

In conclusion, hi flow filter cartridges with innovative technologies are shaping the future of the filtration industry, offering improved performance, smart monitoring capabilities, and sustainable solutions. By embracing these advancements, industries can achieve higher efficiency, lower operating costs, and reduced environmental impact, ensuring a cleaner and healthier future for all.