Installation and Replacement Guide for High Flow Pleated Cartridges

Benefits of High Flow Pleated Cartridges

High flow pleated cartridges are an essential component in many industrial and commercial filtration systems. These cartridges offer numerous benefits that make them a popular choice for those looking to improve the efficiency and effectiveness of their filtration systems. In this article, we will explore the benefits of high flow pleated cartridges and provide a guide for their installation and replacement.

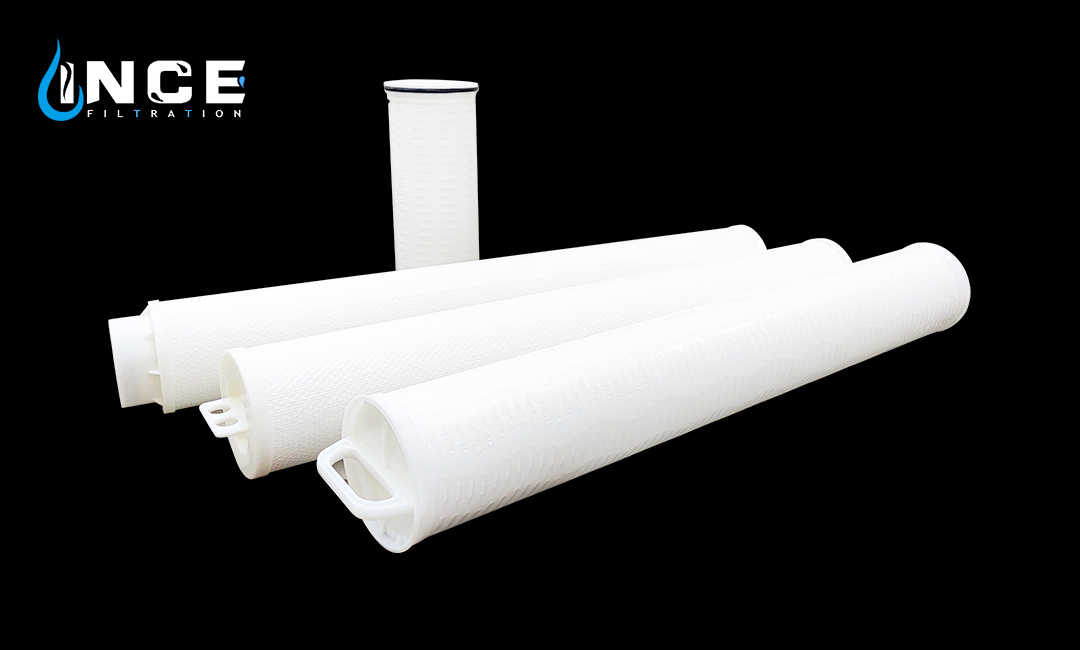

One of the primary benefits of high flow pleated cartridges is their increased filtration capacity. These cartridges are designed to handle higher flow rates than traditional filter cartridges, making them ideal for applications where a large volume of liquid needs to be filtered quickly and efficiently. This increased capacity can help to reduce downtime and improve overall system performance.

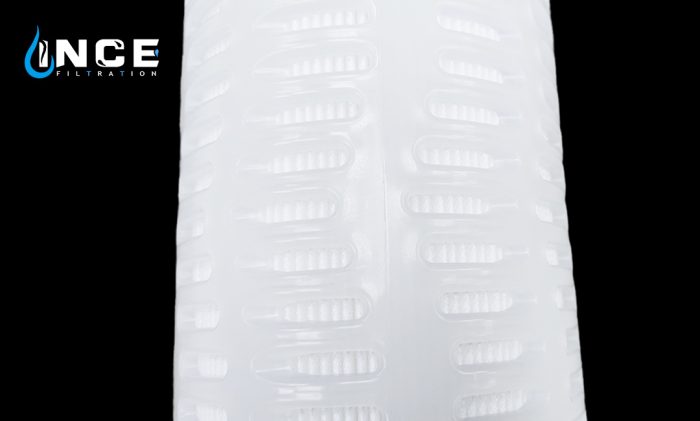

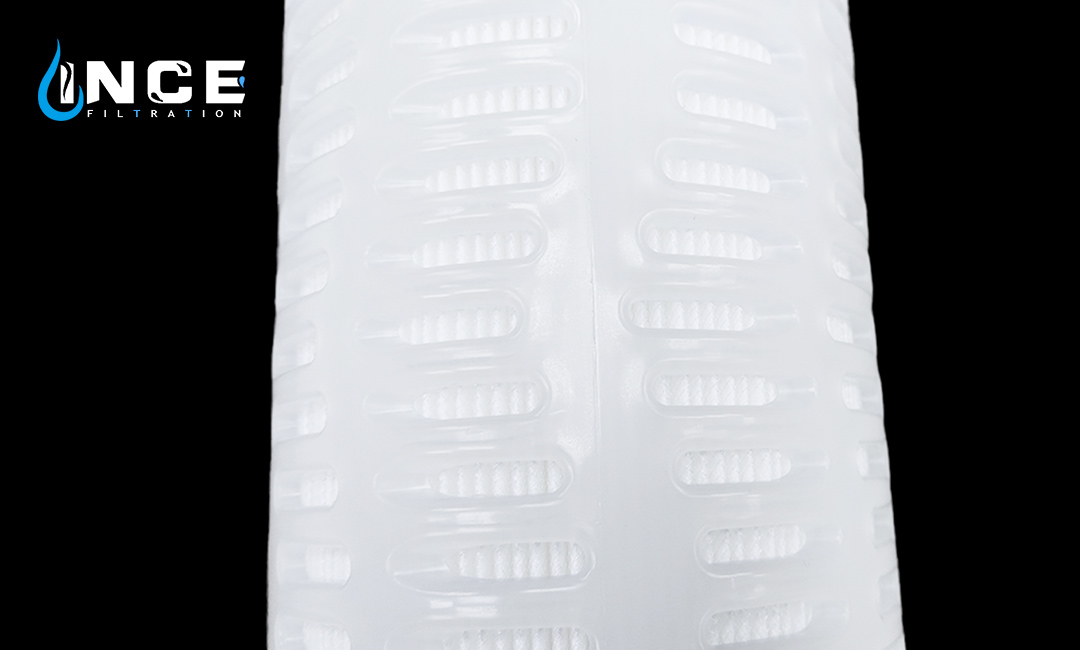

Another key benefit of high flow pleated cartridges is their superior filtration efficiency. The pleated design of these cartridges provides a larger surface area for filtration, allowing them to capture more contaminants and particles than standard filter cartridges. This can help to improve the quality of the filtered liquid and extend the life of downstream equipment.

High flow pleated cartridges are also known for their durability and longevity. These cartridges are constructed from high-quality materials that are designed to withstand the rigors of industrial and commercial filtration applications. This durability can help to reduce maintenance costs and downtime, as the cartridges will need to be replaced less frequently than standard filter cartridges.

In addition to their increased capacity, efficiency, and durability, high flow pleated cartridges are also easy to install and replace. The installation process is straightforward and can typically be completed in a matter of minutes. To install a high flow pleated cartridge, simply remove the old cartridge from the housing, insert the new cartridge, and secure it in place according to the manufacturer’s instructions.

When it comes time to replace a high flow pleated cartridge, the process is equally simple. Start by shutting off the flow of liquid to the filtration system and releasing any built-up pressure. Next, remove the housing cover and carefully remove the old cartridge, taking care not to spill any contaminants. Finally, insert the new cartridge, replace the housing cover, and restart the flow of liquid through the system.

Overall, high flow pleated cartridges offer a range of benefits that make them an excellent choice for industrial and commercial filtration applications. Their increased capacity, efficiency, durability, and ease of installation and replacement make them a cost-effective and reliable option for those looking to improve the performance of their filtration systems. By following the installation and replacement guide outlined in this article, you can ensure that your high flow pleated cartridges continue to provide optimal filtration performance for years to come.

Step-by-Step Installation Guide for High Flow Pleated Cartridges

High flow pleated cartridges are an essential component in many industrial and commercial filtration systems. These cartridges are designed to handle high flow rates while effectively removing contaminants from water or other liquids. Proper installation and replacement of high flow pleated cartridges are crucial to ensure optimal performance and longevity of the filtration system.

To begin the installation process, it is important to first shut off the water supply to the filtration system. This will prevent any water from flowing through the system while you are working on it. Next, carefully remove the housing or filter vessel that contains the old cartridge. Be sure to follow any specific instructions provided by the manufacturer for removing the housing, as different systems may have different methods for accessing the cartridge.

Once the housing is open, carefully remove the old cartridge from the housing. Take note of the orientation of the cartridge, as this will be important when installing the new cartridge. Inspect the old cartridge for any signs of damage or wear, as this may indicate issues with the filtration system that need to be addressed.

Before installing the new high flow pleated cartridge, it is important to properly prepare it for installation. This may involve rinsing the cartridge with clean water to remove any dust or debris that may be present. Additionally, check the seals and gaskets on the cartridge to ensure they are in good condition and will create a tight seal when installed in the housing.

When installing the new cartridge, carefully place it into the housing in the same orientation as the old cartridge. Make sure the cartridge is seated properly and that it is securely in place. Once the cartridge is installed, carefully replace the housing or filter vessel and ensure that it is properly sealed to prevent any leaks.

After the new cartridge is installed, it is important to turn the water supply back on and check for any leaks or issues with the filtration system. Allow the system to run for a few minutes to ensure that water is flowing properly through the new cartridge. If any issues are detected, it may be necessary to recheck the installation of the cartridge or consult with a professional for assistance.

In addition to proper installation, regular replacement of high flow pleated cartridges is essential to maintain the effectiveness of the filtration system. Over time, cartridges can become clogged with contaminants and lose their ability to effectively filter water. It is recommended to replace high flow pleated cartridges according to the manufacturer’s guidelines, which may vary depending on the specific system and usage.

In conclusion, proper installation and replacement of high flow pleated cartridges are essential for maintaining the performance and longevity of industrial and commercial filtration systems. By following the steps outlined in this guide and adhering to manufacturer recommendations, you can ensure that your filtration system continues to operate effectively and efficiently. Remember to always consult with a professional if you encounter any issues or have questions about the installation or replacement process.

Signs that Indicate Replacement of High Flow Pleated Cartridges

High flow pleated cartridges are an essential component of many filtration systems, providing efficient and effective filtration of water and other liquids. Over time, these cartridges can become clogged with debris and contaminants, reducing their effectiveness and potentially causing damage to the filtration system. It is important to regularly inspect and replace high flow pleated cartridges to ensure optimal performance and maintain the quality of the filtered liquid.

One of the key signs that indicate the need for replacement of high flow pleated cartridges is a decrease in flow rate. As the cartridges become clogged with debris, the flow of liquid through the filtration system will be restricted, resulting in a slower flow rate. This can lead to reduced efficiency of the filtration system and may result in inadequate filtration of contaminants. If you notice a decrease in flow rate, it is important to inspect the high flow pleated cartridges and replace them if necessary.

Another sign that indicates the need for replacement of high flow pleated cartridges is a decrease in water quality. If the cartridges are no longer effectively filtering out contaminants, you may notice a change in the taste, odor, or appearance of the filtered liquid. This can be a sign that the cartridges are no longer functioning properly and need to be replaced. Regularly monitoring the quality of the filtered liquid can help you identify when it is time to replace the high flow pleated cartridges.

In addition to decreased flow rate and water quality, another sign that indicates the need for replacement of high flow pleated cartridges is an increase in pressure within the filtration system. As the cartridges become clogged, the pressure within the system will increase as the liquid is forced through the restricted flow path. This can put additional strain on the filtration system and may lead to damage if not addressed promptly. If you notice a significant increase in pressure within the system, it is important to inspect the high flow pleated cartridges and replace them if necessary.

It is important to note that regular maintenance and inspection of high flow pleated cartridges can help prevent these issues from occurring. By following the manufacturer’s guidelines for maintenance and replacement, you can ensure that your filtration system continues to operate efficiently and effectively. In addition, using high-quality replacement cartridges from a reputable supplier can help extend the life of your filtration system and ensure optimal performance.

When it comes time to replace high flow pleated cartridges, it is important to follow the manufacturer’s guidelines for installation. Start by shutting off the water supply to the filtration system and releasing any pressure within the system. Remove the old cartridges carefully, taking care not to damage the housing or any other components of the filtration system. Install the new cartridges according to the manufacturer’s instructions, making sure they are securely in place and properly aligned.

After installing the new high flow pleated cartridges, it is important to flush the system to remove any air pockets and ensure proper flow. Once the system is flushed and running smoothly, you can resume normal operation of the filtration system. Regularly monitoring the flow rate, water quality, and pressure within the system can help you identify when it is time to replace the high flow pleated cartridges again.

In conclusion, regular inspection and replacement of high flow pleated cartridges are essential for maintaining the efficiency and effectiveness of your filtration system. By monitoring the flow rate, water quality, and pressure within the system, you can identify when it is time to replace the cartridges and ensure optimal performance. Following the manufacturer’s guidelines for maintenance and installation can help extend the life of your filtration system and keep it running smoothly.