Key Design Features of Ultipleat High Flow Filters

Benefits of Using Ultipleat High Flow Filters in Industrial Applications

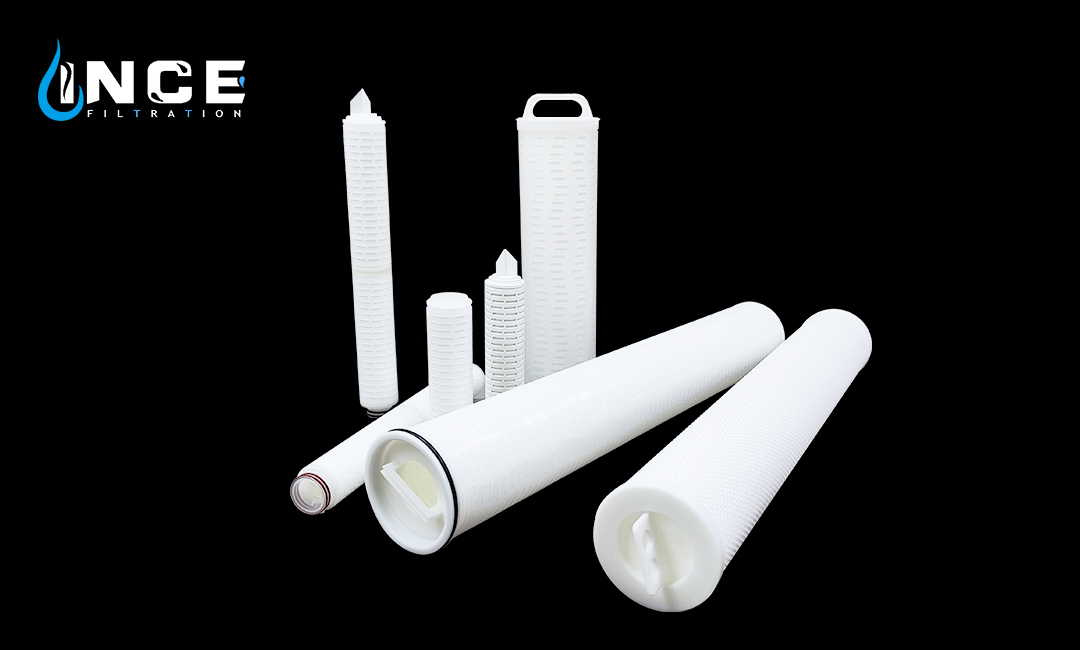

Ultipleat High Flow Filters are a popular choice for industrial applications due to their key design features that offer numerous benefits. These filters are designed to handle high flow rates while maintaining efficiency and durability. One of the key design features of Ultipleat High Flow Filters is their large surface area. This allows for greater dirt-holding capacity and longer service life compared to traditional filters.

In addition to their large surface area, Ultipleat High Flow Filters also feature a graded density structure. This means that the filter media is designed with varying levels of density, with the outer layers capturing larger particles and the inner layers capturing smaller particles. This design helps to improve filtration efficiency and prevent premature clogging of the filter.

Another important design feature of Ultipleat High Flow Filters is their high flow rates. These filters are capable of handling flow rates that are significantly higher than traditional filters, making them ideal for industrial applications where high flow rates are common. This high flow rate capability helps to reduce the number of filters needed in a system, saving both space and money.

Ultipleat High Flow Filters are also designed for easy installation and maintenance. These filters are typically designed with a cartridge-style housing that allows for quick and easy replacement. This means that maintenance can be performed quickly and efficiently, minimizing downtime and maximizing productivity.

Furthermore, Ultipleat High Flow Filters are constructed with high-quality materials that are resistant to chemicals and corrosion. This ensures that the filters can withstand harsh industrial environments without compromising performance. The durable construction of these filters also helps to extend their service life, reducing the frequency of filter replacements and lowering maintenance costs.

Overall, the key design features of Ultipleat High Flow Filters make them an excellent choice for industrial applications. Their large surface area, graded density structure, high flow rates, easy installation and maintenance, and durable construction all contribute to their superior performance and efficiency. By using Ultipleat High Flow Filters in industrial applications, businesses can benefit from improved filtration efficiency, reduced maintenance costs, and increased productivity.

In conclusion, Ultipleat High Flow Filters are a reliable and cost-effective solution for industrial filtration needs. Their key design features set them apart from traditional filters and make them a preferred choice for a wide range of industrial applications. Businesses looking to improve their filtration processes and maximize efficiency should consider incorporating Ultipleat High Flow Filters into their systems.

How Ultipleat High Flow Filters Improve Filtration Efficiency

Ultipleat High Flow Filters are a popular choice for many industries due to their superior filtration efficiency and design features. These filters are designed to handle high flow rates while maintaining excellent particle retention, making them ideal for applications where efficiency is crucial. In this article, we will explore the key design features of Ultipleat High Flow Filters and how they contribute to improved filtration efficiency.

One of the key design features of Ultipleat High Flow Filters is their large surface area. These filters are constructed with pleated media that provides a greater filtration area compared to traditional filters. This increased surface area allows for higher flow rates without sacrificing filtration efficiency. As a result, Ultipleat High Flow Filters can handle larger volumes of fluid while effectively capturing particles, making them a cost-effective solution for many applications.

In addition to their large surface area, Ultipleat High Flow Filters also feature a graded density media construction. This design feature allows for the gradual reduction of pore size from the outside of the filter to the inside. As fluid passes through the filter, larger particles are captured on the outer layers, while smaller particles are trapped deeper within the media. This graded density construction ensures that particles of all sizes are effectively removed, resulting in cleaner fluid and improved filtration efficiency.

Another important design feature of Ultipleat High Flow Filters is their high dirt-holding capacity. These filters are designed to hold a large amount of contaminants before requiring replacement, reducing downtime and maintenance costs. The combination of large surface area, graded density media, and high dirt-holding capacity makes Ultipleat High Flow Filters a reliable choice for applications where continuous filtration is essential.

Furthermore, Ultipleat High Flow Filters are designed for easy installation and maintenance. These filters are available in a variety of sizes and configurations to fit different systems and applications. They can be easily replaced without the need for special tools or equipment, minimizing downtime and ensuring uninterrupted operation. Additionally, Ultipleat High Flow Filters are designed for long service life, reducing the frequency of filter changes and overall operating costs.

Overall, Ultipleat High Flow Filters offer a combination of design features that contribute to improved filtration efficiency. Their large surface area, graded density media construction, high dirt-holding capacity, and ease of installation make them a reliable and cost-effective solution for many industries. Whether used in water treatment, chemical processing, or food and beverage production, Ultipleat High Flow Filters provide superior performance and consistent results.

In conclusion, Ultipleat High Flow Filters are a versatile and efficient filtration solution that can meet the demands of various applications. Their innovative design features ensure optimal performance and reliability, making them a preferred choice for many industries. By investing in Ultipleat High Flow Filters, businesses can improve filtration efficiency, reduce maintenance costs, and achieve cleaner fluid for their operations.

Key Design Features of Ultipleat High Flow Filters for Maximum Performance

Ultipleat High Flow Filters are designed to provide maximum performance in a variety of industrial applications. These filters are known for their high flow rates, efficiency, and durability. In this article, we will discuss some key design features of Ultipleat High Flow Filters that contribute to their exceptional performance.

One of the key design features of Ultipleat High Flow Filters is their large surface area. These filters are designed with pleated media that provides a greater surface area for filtration. This allows for higher flow rates and longer filter life compared to traditional filters. The pleated design also helps to reduce pressure drop, ensuring efficient filtration without sacrificing flow rate.

Another important design feature of Ultipleat High Flow Filters is their high dirt-holding capacity. The pleated media used in these filters is designed to capture and retain a large amount of contaminants, allowing for longer intervals between filter changes. This not only reduces maintenance costs but also ensures consistent filtration performance over time.

In addition to their large surface area and high dirt-holding capacity, Ultipleat High Flow Filters are also designed for easy installation and maintenance. These filters are available in a variety of sizes and configurations to fit different applications. They can be easily installed and replaced, minimizing downtime and ensuring continuous operation.

Ultipleat High Flow Filters are also designed for compatibility with a wide range of fluids and operating conditions. Whether filtering water, chemicals, or oil, these filters are engineered to provide reliable and consistent performance. They are also designed to withstand high temperatures and pressures, making them suitable for demanding industrial environments.

Furthermore, Ultipleat High Flow Filters are constructed with high-quality materials that are resistant to corrosion and degradation. This ensures that the filters will maintain their performance and integrity even in harsh operating conditions. The robust construction of these filters also contributes to their long service life and reliability.

Overall, Ultipleat High Flow Filters are designed with a focus on performance, efficiency, and durability. Their large surface area, high dirt-holding capacity, ease of installation and maintenance, compatibility with various fluids, and robust construction make them an ideal choice for industrial filtration applications.

In conclusion, Ultipleat High Flow Filters are a reliable and efficient solution for industrial filtration needs. Their key design features contribute to their exceptional performance and longevity, making them a valuable investment for any industrial operation. Whether filtering water, chemicals, or oil, Ultipleat High Flow Filters are designed to deliver maximum performance and reliability.

Case Studies Highlighting the Success of Ultipleat High Flow Filters in Various Industries

Ultipleat High Flow Filters are a popular choice in various industries due to their innovative design features that provide efficient and reliable filtration. These filters are designed to handle high flow rates while maintaining a high level of filtration efficiency, making them ideal for applications where large volumes of fluid need to be filtered quickly and effectively.

One key design feature of Ultipleat High Flow Filters is their large surface area. The filters are constructed with pleated filter media that provides a greater surface area compared to traditional filters. This increased surface area allows for higher flow rates without sacrificing filtration efficiency, making Ultipleat High Flow Filters a cost-effective solution for industries that require high flow rates.

In addition to their large surface area, Ultipleat High Flow Filters also feature a graded density design. This design feature allows for the filtration of particles of varying sizes, ensuring that even the smallest contaminants are captured and removed from the fluid. The graded density design also helps to extend the life of the filter by distributing the contaminants evenly across the filter media, preventing premature clogging and ensuring consistent filtration performance.

Another key design feature of Ultipleat High Flow Filters is their robust construction. These filters are built to withstand high pressures and temperatures, making them suitable for a wide range of industrial applications. The filters are made from durable materials that are resistant to corrosion and chemical degradation, ensuring long-lasting performance even in the most demanding environments.

Ultipleat High Flow Filters have been successfully used in a variety of industries, including oil and gas, petrochemical, pharmaceutical, and food and beverage. In the oil and gas industry, these filters are used to remove contaminants from hydraulic fluids, lubricants, and process water, ensuring the smooth operation of equipment and preventing costly downtime. In the petrochemical industry, Ultipleat High Flow Filters are used to purify process streams and remove impurities from raw materials, ensuring the quality and purity of the final products.

In the pharmaceutical industry, Ultipleat High Flow Filters are used to filter pharmaceutical ingredients and final products, ensuring compliance with strict regulatory requirements and maintaining product quality. In the food and beverage industry, these filters are used to remove contaminants from process water, beverages, and food products, ensuring the safety and quality of the final products.

Overall, Ultipleat High Flow Filters are a versatile and reliable filtration solution that offers high flow rates, efficient filtration, and long-lasting performance. With their innovative design features and proven success in various industries, these filters are a popular choice for companies looking to improve their filtration processes and ensure the quality and purity of their products.