Key Features of Spiral Belts for Sludge Dewatering Systems

Benefits of Using Spiral Belts for Sludge Dewatering Systems

Spiral belts are an essential component of sludge dewatering systems, playing a crucial role in the process of separating liquid from solid waste. These belts are designed to withstand the harsh conditions of sludge dewatering, providing a reliable and efficient solution for wastewater treatment plants and other industrial facilities. In this article, we will explore the key features of spiral belts for sludge dewatering systems and discuss the benefits of using them in wastewater treatment processes.

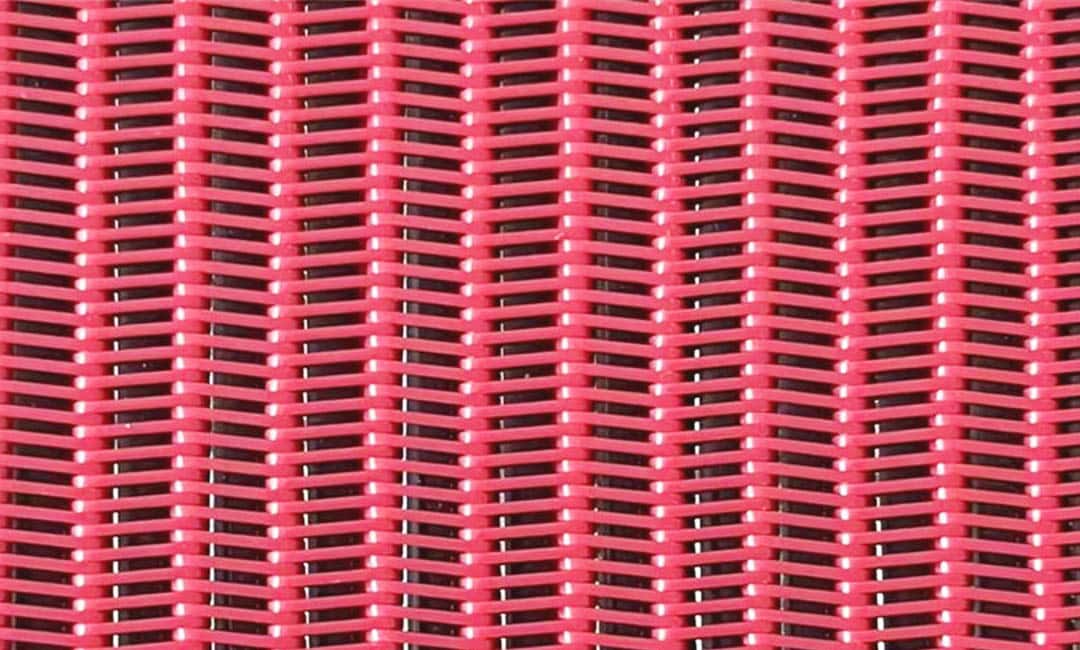

One of the main features of spiral belts is their unique design, which consists of interlocking loops that form a continuous belt. This design allows for efficient drainage of water from the sludge, ensuring that the solid waste is effectively separated from the liquid. The spiral structure of the belt also helps to prevent clogging and blinding, which can occur with other types of dewatering systems.

Another key feature of spiral belts is their high strength and durability. These belts are made from high-quality materials such as polyester or polypropylene, which are resistant to chemicals, abrasion, and corrosion. This makes spiral belts ideal for use in harsh industrial environments where other types of belts may not be able to withstand the conditions.

In addition to their strength and durability, spiral belts are also known for their flexibility and ease of installation. These belts can be easily customized to fit different dewatering systems, allowing for seamless integration into existing wastewater treatment processes. The flexibility of spiral belts also allows for easy maintenance and cleaning, ensuring that the dewatering system operates efficiently and effectively.

One of the main benefits of using spiral belts for sludge dewatering systems is their high dewatering efficiency. The unique design of these belts allows for maximum drainage of water from the sludge, resulting in a higher solids content in the dewatered sludge. This not only reduces the volume of waste that needs to be disposed of but also improves the overall efficiency of the wastewater treatment process.

Another benefit of using spiral belts is their low energy consumption. These belts require minimal power to operate, making them a cost-effective solution for wastewater treatment plants and industrial facilities. By reducing energy consumption, spiral belts help to lower operating costs and improve the sustainability of the dewatering process.

In conclusion, spiral belts are an essential component of sludge dewatering systems, offering a range of benefits for wastewater treatment plants and industrial facilities. Their unique design, high strength, and durability make them an ideal solution for separating liquid from solid waste in a reliable and efficient manner. By using spiral belts in dewatering systems, facilities can improve the efficiency of their wastewater treatment processes, reduce operating costs, and enhance the sustainability of their operations.

Design and Construction of Spiral Belts for Optimal Performance

Spiral belts are an essential component of sludge dewatering systems, playing a crucial role in the efficient removal of water from sludge. These belts are designed to withstand the harsh conditions of sludge dewatering processes, ensuring optimal performance and longevity. In this article, we will explore the key features of spiral belts that make them ideal for sludge dewatering systems.

One of the most important features of spiral belts is their construction. These belts are typically made from high-quality materials such as polyester or polypropylene, which are known for their durability and resistance to chemicals and abrasion. The construction of spiral belts is also designed to provide a smooth surface for sludge to pass through, minimizing the risk of clogging and ensuring efficient dewatering.

Another key feature of spiral belts is their spiral design. This design allows for a large surface area for sludge to come into contact with the belt, maximizing the dewatering process. The spiral configuration also helps to evenly distribute the sludge across the belt, preventing uneven drying and ensuring consistent results.

In addition to their construction and design, spiral belts also feature a number of other important characteristics that contribute to their effectiveness in sludge dewatering systems. For example, many spiral belts are equipped with a special coating that helps to repel water and prevent sludge from sticking to the belt. This coating not only improves the efficiency of the dewatering process but also helps to extend the lifespan of the belt.

Furthermore, spiral belts are designed to be easily adjustable, allowing operators to fine-tune the tension of the belt to achieve optimal dewatering results. This adjustability is crucial in ensuring that the belt is operating at its maximum efficiency, regardless of the type of sludge being processed.

Another important feature of spiral belts is their resistance to corrosion and wear. Sludge dewatering systems can be highly corrosive environments, with chemicals and abrasive materials present in the sludge. Spiral belts are designed to withstand these harsh conditions, ensuring that they remain in good working condition for an extended period of time.

In conclusion, spiral belts are an essential component of sludge dewatering systems, offering a range of features that make them ideal for this demanding application. From their durable construction to their spiral design and special coatings, spiral belts are designed to provide optimal performance and longevity in sludge dewatering processes. By choosing high-quality spiral belts that are specifically designed for sludge dewatering, operators can ensure that their systems operate efficiently and effectively, producing dry, solid sludge for disposal or further processing.

Maintenance Tips for Extending the Lifespan of Spiral Belts in Dewatering Systems

Spiral belts are an essential component of sludge dewatering systems, playing a crucial role in the process of separating liquid from solid waste. These belts are designed to withstand the harsh conditions of dewatering operations, but like any other equipment, they require proper maintenance to ensure optimal performance and longevity.

One key feature of spiral belts is their construction from high-quality materials such as polyester or polypropylene. These materials are chosen for their durability, resistance to chemicals and abrasion, and ability to withstand high temperatures. The weave pattern of the belts is also carefully designed to provide maximum drainage and prevent clogging, ensuring efficient dewatering of sludge.

Another important feature of spiral belts is their flexibility and adaptability to different dewatering applications. These belts can be customized to fit specific system requirements, such as belt width, length, and mesh size. This flexibility allows for optimal performance and efficiency in various sludge dewatering processes.

In addition, spiral belts are designed with a smooth surface to prevent sludge from sticking and accumulating on the belt. This smooth surface reduces friction and wear on the belt, extending its lifespan and reducing maintenance costs. Regular cleaning and maintenance of the belts are essential to prevent buildup and ensure continuous operation.

Proper tensioning of spiral belts is also crucial for optimal performance. Over-tensioning can cause premature wear and damage to the belts, while under-tensioning can lead to slippage and reduced dewatering efficiency. Regular monitoring and adjustment of belt tension are necessary to maintain proper operation and prevent costly repairs.

Regular inspection of spiral belts is essential to identify any signs of wear, damage, or misalignment. Any issues should be addressed promptly to prevent further damage and ensure the longevity of the belts. Replacement of worn or damaged belts should be done in a timely manner to prevent downtime and maintain the efficiency of the dewatering system.

In conclusion, spiral belts are a critical component of sludge dewatering systems, and proper maintenance is essential to ensure their longevity and optimal performance. Key features such as high-quality materials, flexibility, smooth surface, and proper tensioning contribute to the efficiency and effectiveness of these belts in dewatering operations. Regular cleaning, inspection, and timely replacement of worn belts are necessary to prevent costly repairs and downtime. By following these maintenance tips, operators can extend the lifespan of spiral belts and maximize the efficiency of their dewatering systems.