Must-Have Features in High Flow Pleated Filters for Maximum Performance

Benefits of High Flow Pleated Filters

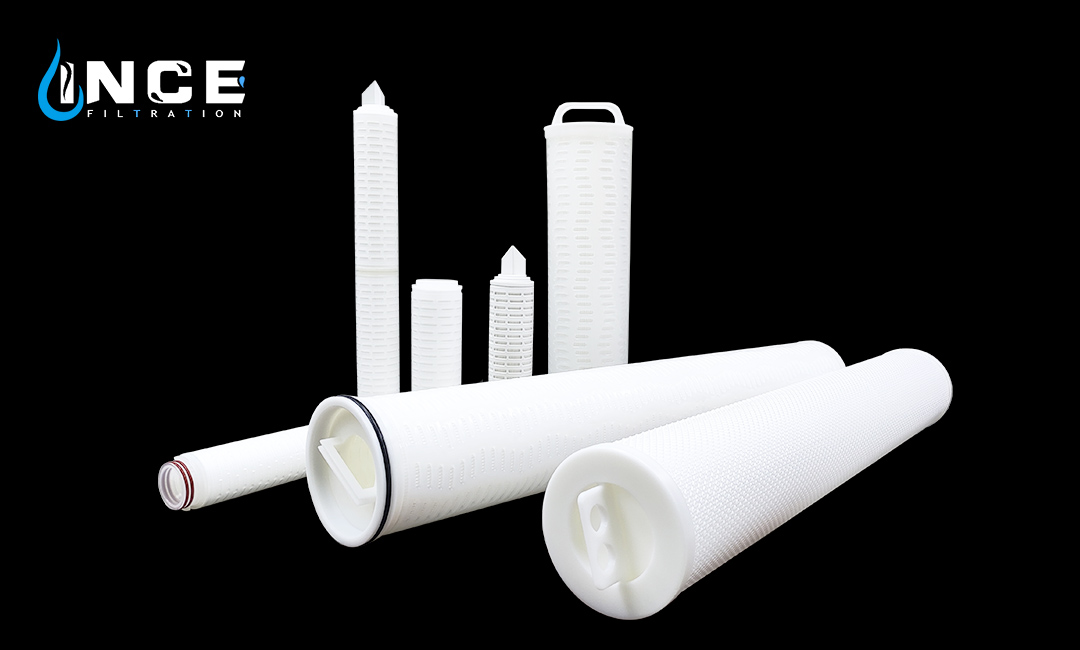

High flow pleated filters are essential components in many industrial and commercial applications where large volumes of liquid need to be filtered quickly and efficiently. These filters are designed to handle high flow rates while maintaining excellent filtration performance, making them ideal for a wide range of applications. In order to achieve maximum performance, it is important to choose high flow pleated filters that have the right features. In this article, we will discuss some of the must-have features in high flow pleated filters that can help you get the most out of your filtration system.

One of the key features to look for in high flow pleated filters is a large surface area. A larger surface area allows the filter to capture more contaminants and particles, resulting in better filtration efficiency. High flow pleated filters with a large surface area can handle higher flow rates without sacrificing filtration performance, making them ideal for applications where high flow rates are required.

Another important feature to consider is the filter media. High flow pleated filters are available in a variety of media types, including polypropylene, polyester, and fiberglass. Each type of media has its own unique properties and advantages, so it is important to choose a filter media that is suitable for your specific application. For example, polypropylene filters are resistant to chemicals and are ideal for applications where chemical compatibility is important, while polyester filters are more durable and can withstand higher temperatures.

In addition to surface area and filter media, the pleat design of high flow pleated filters is also an important factor to consider. Pleated filters with a uniform pleat design can provide better filtration performance and longer service life compared to filters with irregular pleat patterns. A uniform pleat design ensures that the filter media is evenly distributed, allowing for more efficient filtration and preventing premature clogging of the filter.

Furthermore, the construction of the filter housing is another important feature to consider when choosing high flow pleated filters. The housing should be made of durable materials that can withstand high flow rates and pressure, ensuring that the filter remains intact and performs optimally under demanding conditions. Additionally, the housing should be designed to minimize bypass and ensure that all liquid passes through the filter media, maximizing filtration efficiency.

Lastly, it is important to consider the micron rating of high flow pleated filters. The micron rating indicates the size of particles that the filter can capture, with lower micron ratings indicating finer filtration. Choosing a filter with the right micron rating for your application is crucial to ensure that the filter can effectively remove contaminants and particles from the liquid stream.

In conclusion, high flow pleated filters are essential components in many industrial and commercial applications where high flow rates and efficient filtration are required. By choosing high flow pleated filters with the right features, such as a large surface area, appropriate filter media, uniform pleat design, durable housing, and the right micron rating, you can ensure maximum performance and longevity of your filtration system. Investing in high-quality high flow pleated filters with these must-have features will help you achieve optimal filtration efficiency and protect your equipment from contaminants and particles.

Importance of Micron Rating in High Flow Pleated Filters

High flow pleated filters are essential components in many industrial and commercial applications, where the need for efficient filtration of large volumes of liquid is paramount. These filters are designed to handle high flow rates while maintaining excellent filtration efficiency, making them ideal for use in a wide range of industries, including water treatment, chemical processing, and food and beverage production.

One of the key factors that determine the performance of high flow pleated filters is the micron rating. The micron rating of a filter refers to the size of particles that the filter can effectively capture. Filters with a lower micron rating are capable of capturing smaller particles, while filters with a higher micron rating are better suited for capturing larger particles.

In high flow applications, it is crucial to select a filter with the appropriate micron rating to ensure optimal performance. Filters with a micron rating that is too high may allow smaller particles to pass through, compromising the quality of the filtrate. On the other hand, filters with a micron rating that is too low may become clogged quickly, leading to reduced flow rates and increased maintenance requirements.

When choosing a high flow pleated filter, it is important to consider the specific requirements of the application. For applications where fine filtration is necessary, such as in the pharmaceutical or semiconductor industries, a filter with a low micron rating, such as 1 or 5 microns, may be required. These filters are capable of capturing even the smallest particles, ensuring that the filtrate meets the desired quality standards.

In contrast, applications that involve the filtration of larger particles, such as in the mining or wastewater treatment industries, may benefit from a filter with a higher micron rating, such as 50 or 100 microns. These filters are designed to handle larger particles without becoming clogged, making them ideal for high flow applications where efficiency is key.

In addition to the micron rating, there are several other features that are essential for maximizing the performance of high flow pleated filters. One such feature is the filter media. High flow pleated filters are typically made from a variety of materials, including polypropylene, polyester, and fiberglass. Each type of filter media has its own unique properties, such as chemical compatibility, temperature resistance, and dirt-holding capacity, which can impact the performance of the filter.

Another important feature to consider is the pleat design of the filter. Pleated filters are designed to maximize the surface area available for filtration, allowing for greater dirt-holding capacity and longer service life. Filters with a high pleat count and deep pleats are more effective at capturing particles and maintaining flow rates than filters with a lower pleat count or shallower pleats.

Furthermore, the construction of the filter housing is also critical for ensuring the performance of high flow pleated filters. The housing should be made from durable materials that can withstand the high flow rates and pressures typically encountered in industrial applications. Additionally, the housing should be designed to minimize bypass and ensure that all liquid passes through the filter media, maximizing filtration efficiency.

In conclusion, the micron rating, filter media, pleat design, and housing construction are all important features to consider when selecting high flow pleated filters for maximum performance. By choosing a filter that meets the specific requirements of the application and incorporates these key features, users can ensure efficient filtration and reliable operation in their industrial processes.

Material Options for High Flow Pleated Filters

High flow pleated filters are essential components in many industrial and commercial applications where high flow rates and efficient filtration are required. These filters are designed to handle large volumes of liquid or gas while maintaining high levels of filtration efficiency. When it comes to selecting the right high flow pleated filter for your specific application, there are several key features to consider to ensure maximum performance.

One of the most important factors to consider when choosing a high flow pleated filter is the material used in its construction. The material of the filter plays a crucial role in determining its overall performance and durability. There are several material options available for high flow pleated filters, each with its own set of advantages and disadvantages.

One common material used in high flow pleated filters is polyester. Polyester filters are known for their high strength and durability, making them ideal for applications where the filter will be exposed to harsh conditions or high flow rates. Polyester filters are also resistant to chemicals and can withstand high temperatures, making them suitable for a wide range of industrial applications.

Another popular material option for high flow pleated filters is polypropylene. Polypropylene filters are lightweight and cost-effective, making them a popular choice for applications where budget is a concern. Polypropylene filters are also resistant to chemicals and have a high flow rate capacity, making them suitable for applications where efficient filtration is essential.

In addition to polyester and polypropylene, high flow pleated filters can also be made from other materials such as nylon, fiberglass, and stainless steel. Each material has its own unique set of properties that make it suitable for specific applications. For example, nylon filters are known for their high chemical resistance, while fiberglass filters are lightweight and have a high dirt-holding capacity.

When selecting a material for your high flow pleated filter, it is important to consider the specific requirements of your application. Factors such as flow rate, temperature, pressure, and chemical compatibility should all be taken into account when choosing the right material for your filter. By selecting the appropriate material, you can ensure that your high flow pleated filter will perform optimally and provide maximum filtration efficiency.

In conclusion, the material used in high flow pleated filters plays a critical role in determining their overall performance and durability. By selecting the right material for your specific application, you can ensure that your filter will provide maximum filtration efficiency and meet the demands of your operation. Whether you choose polyester, polypropylene, nylon, fiberglass, or stainless steel, each material has its own unique set of properties that make it suitable for different applications. By understanding the advantages and disadvantages of each material option, you can make an informed decision and select the best high flow pleated filter for your needs.

Maintenance Tips for High Flow Pleated Filters

High flow pleated filters are essential components in many industrial and commercial applications, providing efficient filtration of liquids and gases to ensure optimal performance of equipment and machinery. To maximize the effectiveness of these filters, it is important to consider certain key features that can enhance their performance and longevity.

One of the most important features to look for in high flow pleated filters is a large surface area. Filters with a greater surface area can capture more contaminants and particles, resulting in improved filtration efficiency and longer filter life. This is especially important in high flow applications where a large volume of fluid or gas needs to be filtered quickly and effectively.

Another crucial feature to consider is the filter media material. High-quality filter media can make a significant difference in the performance of the filter. Materials such as polyester, polypropylene, and fiberglass are commonly used in high flow pleated filters due to their durability and ability to capture a wide range of contaminants. It is important to choose a filter with the appropriate media material for the specific application to ensure optimal filtration performance.

In addition to surface area and filter media material, the pleat design of the filter is also an important factor to consider. Pleated filters with a uniform and consistent pleat design can provide better support for the filter media, preventing collapse and ensuring even distribution of flow throughout the filter. This can help to prevent bypass and ensure that all contaminants are captured effectively.

Furthermore, the construction of the filter housing is another key feature to consider. A sturdy and durable housing can protect the filter media from damage and ensure that the filter can withstand high flow rates and pressure levels. It is important to choose a filter with a housing that is compatible with the specific operating conditions of the application to prevent leaks and ensure reliable filtration performance.

Additionally, it is important to consider the micron rating of the filter. The micron rating indicates the size of particles that the filter can capture, with lower micron ratings indicating finer filtration. In high flow applications where the presence of small particles can cause damage to equipment or affect product quality, it is important to choose a filter with a low micron rating to ensure thorough filtration.

Lastly, ease of maintenance is another important feature to consider in high flow pleated filters. Filters that are easy to install, replace, and clean can help to minimize downtime and maintenance costs. Look for filters that are designed for quick and easy maintenance, with features such as tool-free installation and replacement, and easy access to the filter housing.

In conclusion, high flow pleated filters are essential components in many industrial and commercial applications, providing efficient filtration of liquids and gases to ensure optimal performance of equipment and machinery. By considering key features such as surface area, filter media material, pleat design, housing construction, micron rating, and ease of maintenance, you can maximize the performance and longevity of your filters. Choose high-quality filters with these must-have features to ensure reliable and effective filtration in your high flow applications.