Pleated Filter Cartridges vs. Depth Filters: Which Is Better?

Pros and Cons of Pleated Filter Cartridges

When it comes to choosing the right filter for your filtration system, there are many factors to consider. Two common types of filters used in industrial and commercial applications are pleated filter cartridges and depth filters. Both have their own set of pros and cons, and understanding the differences between the two can help you make an informed decision on which type of filter is best suited for your specific needs.

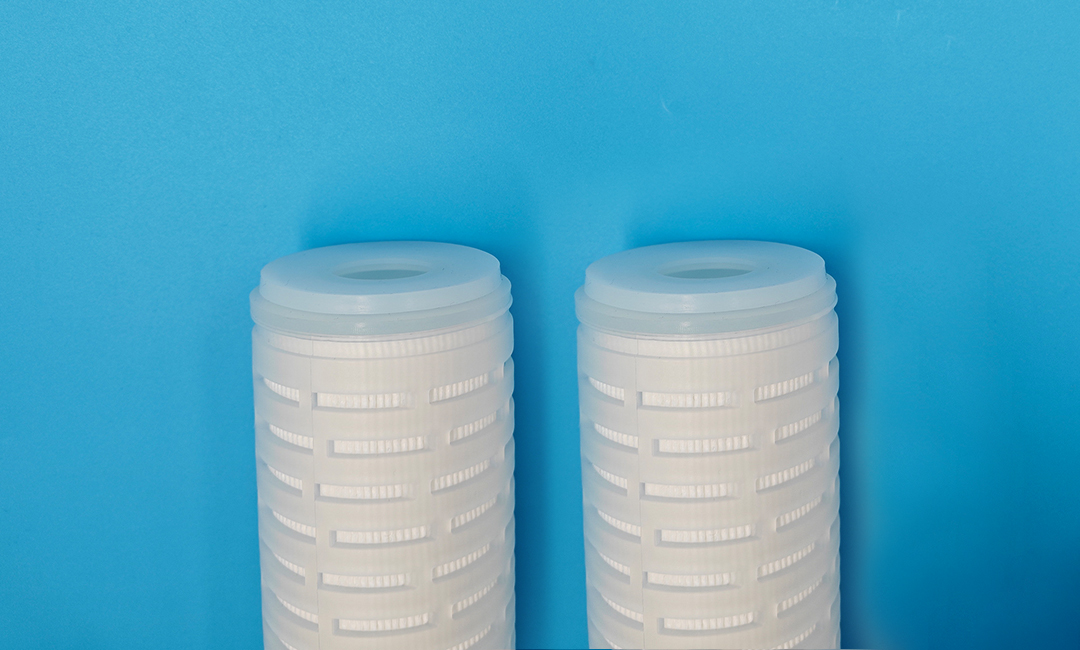

Pleated filter cartridges are a popular choice for many applications due to their high efficiency and long service life. These filters are made up of a series of pleats that increase the surface area available for filtration, allowing for greater dirt-holding capacity and longer intervals between filter changes. This can result in cost savings over time, as fewer filter replacements are needed.

One of the key advantages of pleated filter cartridges is their ability to remove a wide range of contaminants, including particles as small as 0.2 microns. This makes them ideal for applications where fine filtration is required, such as in the pharmaceutical, food and beverage, and electronics industries. Additionally, pleated filter cartridges are easy to install and replace, making maintenance quick and hassle-free.

However, pleated filter cartridges also have some drawbacks that should be taken into consideration. One of the main disadvantages is their higher initial cost compared to depth filters. While pleated filter cartridges may offer long-term cost savings due to their extended service life, the upfront investment can be a deterrent for some users.

Another potential downside of pleated filter cartridges is their susceptibility to clogging. The pleats in the filter can become blocked with debris over time, reducing the flow rate and efficiency of the filtration system. Regular maintenance and monitoring are necessary to prevent clogging and ensure optimal performance.

Despite these drawbacks, pleated filter cartridges remain a popular choice for many applications due to their high efficiency and versatility. Their ability to remove a wide range of contaminants and long service life make them a reliable option for industries that require fine filtration.

In conclusion, pleated filter cartridges offer a number of advantages, including high efficiency, long service life, and versatility. However, they also have some drawbacks, such as higher initial cost and susceptibility to clogging. Understanding the pros and cons of pleated filter cartridges can help you determine whether they are the right choice for your filtration needs.

Advantages and Disadvantages of Depth Filters

Depth filters are a common type of filtration system used in various industries to remove impurities from liquids. They are known for their ability to capture particles throughout the entire thickness of the filter media, making them effective at removing a wide range of contaminants. However, like any filtration system, depth filters have their own set of advantages and disadvantages that should be considered when choosing the right filter for a specific application.

One of the main advantages of depth filters is their high dirt-holding capacity. Because they capture particles throughout the entire depth of the filter media, depth filters can hold a large amount of contaminants before needing to be replaced. This makes them ideal for applications where a high level of filtration is required over an extended period of time.

Another advantage of depth filters is their ability to remove a wide range of particle sizes. Unlike pleated filter cartridges, which are designed to capture larger particles on the surface of the filter media, depth filters can capture particles of varying sizes throughout the entire thickness of the filter. This makes them versatile and effective at removing both large and small contaminants from liquids.

Depth filters are also known for their low pressure drop. Because they have a larger surface area compared to pleated filter cartridges, depth filters allow for a higher flow rate with minimal resistance. This can result in energy savings and increased efficiency in filtration systems.

However, depth filters also have some disadvantages that should be taken into consideration. One of the main drawbacks of depth filters is their limited particle retention efficiency. While they are effective at capturing a wide range of particle sizes, depth filters may not be as efficient at removing smaller particles compared to pleated filter cartridges. This can be a concern in applications where fine filtration is required.

Another disadvantage of depth filters is their tendency to clog more quickly than pleated filter cartridges. Because they capture particles throughout the entire thickness of the filter media, depth filters can become clogged with contaminants more easily, leading to a shorter lifespan and more frequent replacements. This can result in higher maintenance costs and downtime in filtration systems.

In conclusion, depth filters have both advantages and disadvantages that should be considered when choosing the right filtration system for a specific application. While they offer high dirt-holding capacity, versatility in particle size removal, and low pressure drop, depth filters may have limitations in particle retention efficiency and susceptibility to clogging. Ultimately, the decision between depth filters and pleated filter cartridges will depend on the specific requirements of the application and the desired level of filtration efficiency.

Performance Comparison of Pleated Filter Cartridges and Depth Filters

When it comes to choosing the right filtration system for your industrial or commercial needs, there are a variety of options available on the market. Two popular choices are pleated filter cartridges and depth filters. Both types of filters have their own unique features and benefits, but which one is better? In this article, we will compare pleated filter cartridges and depth filters in terms of performance to help you make an informed decision.

Pleated filter cartridges are made up of a series of pleats that increase the surface area of the filter, allowing for greater filtration efficiency. These filters are typically made from materials such as polyester, polypropylene, or cellulose, and are designed to remove particles as small as 0.2 microns. Pleated filter cartridges are known for their high dirt-holding capacity and long service life, making them a popular choice for applications where high flow rates and low pressure drops are required.

On the other hand, depth filters are made up of a thick layer of filtration media, such as cellulose, diatomaceous earth, or activated carbon. These filters work by trapping particles throughout the depth of the media, rather than just on the surface like pleated filter cartridges. Depth filters are known for their high dirt-loading capacity and ability to remove a wide range of contaminants, making them ideal for applications where fine filtration is required.

In terms of filtration efficiency, pleated filter cartridges are generally more effective at removing smaller particles than depth filters. This is due to the pleated design of the filter, which provides a larger surface area for particles to be trapped. Pleated filter cartridges are also more efficient at maintaining a consistent flow rate and pressure drop over time, as the pleats help to prevent clogging and reduce the need for frequent filter changes.

Depth filters, on the other hand, are better suited for applications where a high dirt-loading capacity is required. The thick layer of filtration media in depth filters allows them to hold a larger amount of contaminants before needing to be replaced, making them a cost-effective option for applications with high levels of particulate matter.

When it comes to service life, pleated filter cartridges typically have a longer lifespan than depth filters. This is due to the pleated design of the filter, which helps to prevent premature clogging and extends the time between filter changes. Depth filters, on the other hand, may need to be replaced more frequently due to their lower dirt-holding capacity.

In conclusion, both pleated filter cartridges and depth filters have their own unique advantages and disadvantages. Pleated filter cartridges are more efficient at removing smaller particles and maintaining a consistent flow rate, while depth filters are better suited for applications with high dirt-loading capacity. Ultimately, the choice between pleated filter cartridges and depth filters will depend on your specific filtration needs and requirements.