The Advantages of Spiral Conveyor Belts for Drying Applications

Increased Efficiency in Drying Processes

Spiral conveyor belts have become increasingly popular in drying applications due to their numerous advantages over traditional conveyor systems. These belts are designed to maximize efficiency and productivity in the drying process, making them a valuable asset for industries that rely on effective drying methods.

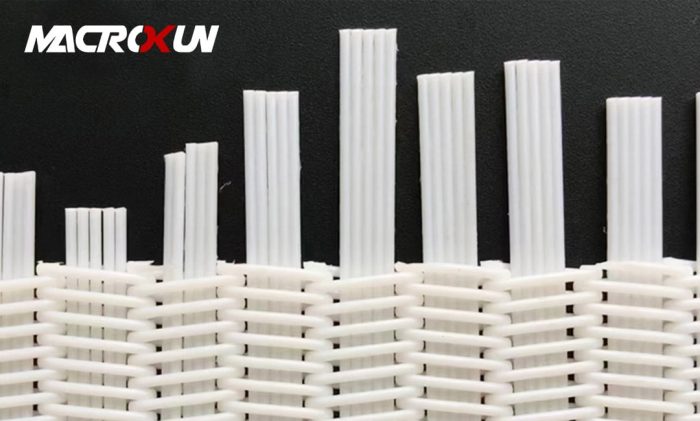

One of the key advantages of spiral conveyor belts is their space-saving design. These belts are able to convey materials in a vertical or horizontal direction, allowing for a more compact layout in the drying area. This means that businesses can maximize their floor space and increase the overall efficiency of their drying process. Additionally, spiral conveyor belts can be customized to fit specific space requirements, making them a versatile option for a wide range of drying applications.

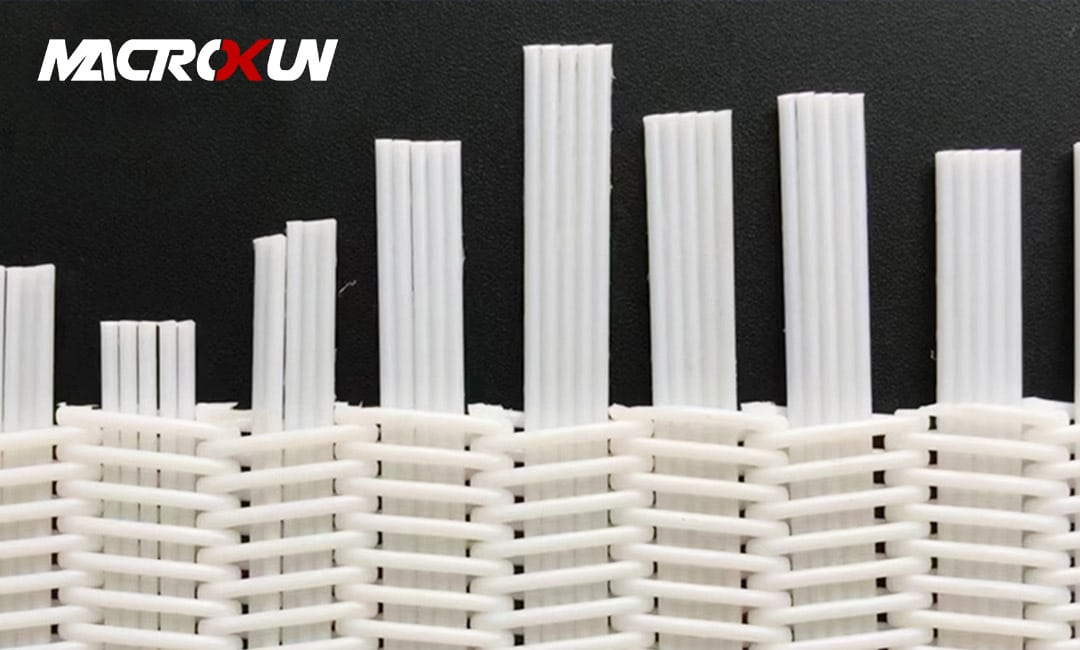

In addition to their space-saving design, spiral conveyor belts are also known for their gentle handling of materials. The unique spiral design of these belts allows for a smooth and continuous flow of materials, reducing the risk of damage or breakage during the drying process. This gentle handling is especially important for delicate or fragile materials that require careful treatment to maintain their quality and integrity.

Another advantage of spiral conveyor belts is their ability to handle a wide range of materials and products. These belts can be customized with different belt materials, widths, and configurations to accommodate various types of products, making them a versatile option for businesses with diverse drying needs. Whether drying food products, textiles, or industrial materials, spiral conveyor belts can provide a reliable and efficient solution for the drying process.

Furthermore, spiral conveyor belts are designed for easy maintenance and cleaning, reducing downtime and ensuring consistent performance. These belts are constructed with durable materials that are resistant to wear and tear, making them a long-lasting investment for businesses looking to improve their drying processes. Additionally, the open design of spiral conveyor belts allows for easy access to all parts of the belt, making maintenance and cleaning simple and efficient.

Overall, the advantages of spiral conveyor belts for drying applications are clear. These belts offer a space-saving design, gentle handling of materials, versatility in handling different products, and easy maintenance and cleaning. By incorporating spiral conveyor belts into their drying processes, businesses can increase efficiency, productivity, and overall quality in their operations. With their numerous benefits, spiral conveyor belts are a valuable asset for industries looking to optimize their drying processes and improve their bottom line.

Space-saving Design for Compact Facilities

Spiral conveyor belts are a popular choice for drying applications in various industries due to their space-saving design. These belts offer several advantages that make them ideal for use in compact facilities where space is limited.

One of the main advantages of spiral conveyor belts is their ability to maximize floor space. Traditional straight conveyors require a significant amount of linear space to transport materials from one point to another. In contrast, spiral conveyor belts utilize vertical space by spiraling upwards, allowing for more efficient use of floor space. This is particularly beneficial for facilities with limited space or those looking to optimize their layout for increased productivity.

Additionally, spiral conveyor belts are versatile and can be customized to fit the specific needs of a drying application. They can be designed to accommodate various product sizes and shapes, making them suitable for a wide range of industries. Whether drying food products, textiles, or industrial materials, spiral conveyor belts can be tailored to meet the unique requirements of each application.

Another advantage of spiral conveyor belts is their gentle handling of products during the drying process. The spiral design allows for a smooth and continuous flow of materials, reducing the risk of damage or breakage. This is especially important for delicate or fragile products that require careful handling to maintain their quality. By using a spiral conveyor belt, manufacturers can ensure that their products are dried evenly and without any damage.

Furthermore, spiral conveyor belts are easy to clean and maintain, making them a cost-effective solution for drying applications. The open design of the belt allows for easy access to all components, making it simple to clean and sanitize. This is essential for industries that require strict hygiene standards, such as food processing or pharmaceuticals. Additionally, spiral conveyor belts are durable and long-lasting, reducing the need for frequent repairs or replacements.

In conclusion, spiral conveyor belts offer several advantages for drying applications in compact facilities. Their space-saving design maximizes floor space, while their versatility allows for customization to fit specific needs. The gentle handling of products ensures that they are dried evenly and without damage, while the easy cleaning and maintenance make them a cost-effective solution. Overall, spiral conveyor belts are an excellent choice for industries looking to optimize their drying processes in a space-efficient and efficient manner.

Enhanced Product Quality and Consistency

Spiral conveyor belts are a popular choice for drying applications in various industries due to their numerous advantages. One of the key benefits of using spiral conveyor belts for drying is the enhanced product quality and consistency that they provide.

When it comes to drying products, maintaining a consistent temperature and airflow is crucial to ensure that the products are dried evenly and thoroughly. Spiral conveyor belts are designed to provide a uniform drying environment, allowing for consistent drying results across all products. This helps to prevent over-drying or under-drying, which can lead to product spoilage or quality issues.

In addition to providing a consistent drying environment, spiral conveyor belts also offer excellent product handling capabilities. The unique design of spiral conveyor belts allows for gentle product handling, reducing the risk of product damage or breakage during the drying process. This is especially important for delicate or fragile products that require careful handling to maintain their quality.

Another advantage of using spiral conveyor belts for drying applications is their space-saving design. Spiral conveyor belts are compact and can be installed in tight spaces, making them ideal for facilities with limited floor space. This allows for efficient use of space and maximizes the drying capacity of the facility.

Furthermore, spiral conveyor belts are easy to clean and maintain, which is essential for ensuring product quality and preventing contamination. The open design of spiral conveyor belts allows for easy access to all parts of the belt, making cleaning and maintenance tasks quick and simple. This helps to reduce downtime and ensure that the drying process runs smoothly without any interruptions.

In addition to their practical advantages, spiral conveyor belts are also energy-efficient, which can lead to cost savings for businesses. The efficient design of spiral conveyor belts allows for optimal airflow and heat distribution, reducing energy consumption and lowering operating costs. This makes spiral conveyor belts a sustainable and cost-effective solution for drying applications.

Overall, the advantages of using spiral conveyor belts for drying applications are clear. From enhanced product quality and consistency to space-saving design and energy efficiency, spiral conveyor belts offer a range of benefits that can help businesses improve their drying processes and achieve better results. By investing in spiral conveyor belts for drying applications, businesses can ensure that their products are dried efficiently and effectively, leading to higher quality products and increased customer satisfaction.