The Efficiency of Polyester Mesh Drying Belts in Industrial Applications

Advantages of Polyester Mesh Drying Belts in Industrial Processes

Polyester mesh drying belts have emerged as a vital component in various industrial applications, particularly in processes that require efficient moisture removal. One of the primary advantages of these belts is their exceptional durability. Made from high-quality polyester fibers, they are designed to withstand the rigors of continuous operation, including exposure to heat, chemicals, and mechanical stress. This resilience not only extends the lifespan of the drying equipment but also reduces the frequency of replacements, leading to significant cost savings for manufacturers.

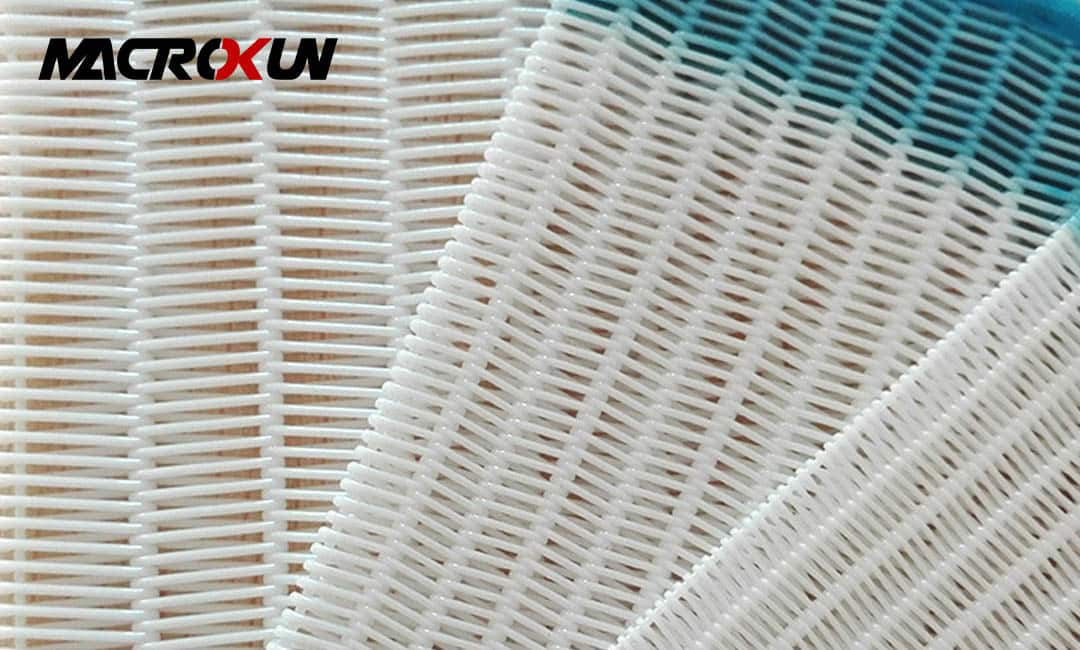

In addition to their durability, polyester mesh drying belts offer excellent airflow characteristics. The open mesh design allows for optimal air circulation, which is crucial in drying processes. This enhanced airflow facilitates quicker moisture evaporation, thereby increasing the overall efficiency of the drying operation. As a result, industries can achieve faster production cycles, which is particularly beneficial in high-demand environments where time is of the essence. Furthermore, the ability to dry products more rapidly without compromising quality is a significant advantage that polyester mesh belts provide.

Another noteworthy benefit of polyester mesh drying belts is their versatility. These belts can be utilized in a wide range of applications, from food processing to textile manufacturing. In the food industry, for instance, they are employed to dry fruits, vegetables, and other products, ensuring that moisture levels are adequately controlled to prevent spoilage. Similarly, in the textile sector, these belts are used to dry fabrics and other materials, contributing to the overall efficiency of the production process. This adaptability makes polyester mesh drying belts an invaluable asset across various industries, allowing for seamless integration into existing systems.

Moreover, the ease of maintenance associated with polyester mesh drying belts cannot be overlooked. Their design allows for straightforward cleaning, which is essential in maintaining hygiene standards, especially in food-related applications. Regular maintenance not only ensures optimal performance but also helps in prolonging the life of the belts. This ease of upkeep is a significant advantage for manufacturers, as it minimizes downtime and enhances productivity.

The thermal stability of polyester mesh drying belts is another critical factor that contributes to their efficiency in industrial processes. These belts can operate effectively at elevated temperatures, making them suitable for high-temperature drying applications. This capability allows industries to implement more aggressive drying techniques, further improving moisture removal rates. Consequently, manufacturers can optimize their processes, leading to enhanced product quality and reduced energy consumption.

In addition to these practical benefits, the use of polyester mesh drying belts aligns with sustainability goals. As industries increasingly focus on reducing their environmental impact, the energy efficiency of drying processes becomes paramount. Polyester mesh belts, with their ability to facilitate faster drying times and lower energy consumption, contribute to more sustainable manufacturing practices. This alignment with eco-friendly initiatives not only enhances a company’s reputation but also meets the growing consumer demand for environmentally responsible products.

In conclusion, the advantages of polyester mesh drying belts in industrial processes are manifold. Their durability, excellent airflow characteristics, versatility, ease of maintenance, thermal stability, and contribution to sustainability make them an essential component in various applications. As industries continue to seek ways to improve efficiency and reduce costs, the adoption of polyester mesh drying belts is likely to increase, solidifying their role as a cornerstone in modern industrial drying solutions.

Comparison of Polyester Mesh Drying Belts with Traditional Drying Methods

Polyester mesh drying belts have become a popular choice in industrial applications due to their efficiency and effectiveness in the drying process. In comparison to traditional drying methods, such as air drying or using metal conveyor belts, polyester mesh drying belts offer several advantages that make them a superior option for many industries.

One of the key benefits of polyester mesh drying belts is their ability to provide a consistent and uniform drying process. The open mesh design of these belts allows for optimal airflow, ensuring that heat is evenly distributed across the surface of the material being dried. This results in a more efficient drying process, as the material is exposed to consistent heat levels throughout the entire drying cycle.

In contrast, traditional drying methods often result in uneven drying, with certain areas of the material drying faster than others. This can lead to inconsistencies in the final product, as well as increased drying times and energy consumption. Polyester mesh drying belts eliminate these issues by providing a uniform drying environment that ensures all parts of the material are dried evenly and efficiently.

Another advantage of polyester mesh drying belts is their durability and longevity. Made from high-quality polyester materials, these belts are designed to withstand the rigors of industrial drying processes. They are resistant to wear and tear, as well as chemicals and high temperatures, making them a reliable and long-lasting option for industrial applications.

In comparison, traditional drying methods, such as air drying or metal conveyor belts, may not offer the same level of durability and longevity. Air drying, for example, is often slow and inefficient, requiring large amounts of space and time to dry materials effectively. Metal conveyor belts, on the other hand, can be prone to corrosion and damage over time, leading to increased maintenance costs and downtime.

Polyester mesh drying belts also offer a high level of flexibility and customization, allowing them to be tailored to specific drying requirements. With a wide range of mesh sizes and belt configurations available, these belts can be customized to accommodate different materials and drying processes. This flexibility makes polyester mesh drying belts a versatile option for a variety of industrial applications, from food processing to textiles and beyond.

In contrast, traditional drying methods may not offer the same level of customization and adaptability. Air drying, for example, is limited by environmental factors such as temperature and humidity, which can impact the effectiveness of the drying process. Metal conveyor belts may also be limited in their ability to accommodate different materials and drying requirements, leading to inefficiencies and inconsistencies in the drying process.

Overall, polyester mesh drying belts offer a superior option for industrial drying applications, providing a consistent, efficient, and durable solution that can be customized to meet specific drying requirements. With their many advantages over traditional drying methods, polyester mesh drying belts are becoming the preferred choice for industries looking to improve their drying processes and increase efficiency.

Maintenance and Longevity of Polyester Mesh Drying Belts in Manufacturing

Polyester mesh drying belts have become an integral component in various industrial applications, particularly in manufacturing processes that require efficient moisture removal. The longevity and maintenance of these belts are crucial factors that directly influence operational efficiency and cost-effectiveness. Understanding the maintenance requirements and the factors that contribute to the durability of polyester mesh drying belts can significantly enhance their performance and lifespan.

One of the primary advantages of polyester mesh drying belts is their resistance to wear and tear, which is essential in high-demand environments. However, despite their robust nature, regular maintenance is necessary to ensure optimal performance. Routine inspections should be conducted to identify any signs of damage or wear, such as fraying edges or holes. Addressing these issues promptly can prevent further deterioration and extend the life of the belt. Additionally, keeping the belts clean is vital, as the accumulation of debris and contaminants can impede their functionality. A simple cleaning regimen, involving the use of mild detergents and water, can effectively remove buildup without damaging the material.

Moreover, the operating environment plays a significant role in the longevity of polyester mesh drying belts. Factors such as temperature, humidity, and exposure to chemicals can affect the integrity of the belts. For instance, high temperatures may lead to thermal degradation, while exposure to harsh chemicals can cause the material to break down. Therefore, it is essential to assess the specific conditions in which the belts operate and make necessary adjustments to mitigate potential risks. Implementing protective measures, such as using guards or shields, can further enhance the durability of the belts by minimizing exposure to harmful elements.

Another critical aspect of maintaining polyester mesh drying belts is ensuring proper tension and alignment during operation. Incorrect tension can lead to uneven wear, resulting in premature failure. Regularly checking and adjusting the tension according to the manufacturer’s specifications can help maintain uniformity and prevent unnecessary strain on the material. Additionally, ensuring that the belts are properly aligned with the rollers and other components of the drying system is essential. Misalignment can cause friction and additional wear, ultimately reducing the lifespan of the belts.

Furthermore, the choice of the right polyester mesh material is fundamental to the efficiency and longevity of drying belts. Different applications may require specific mesh sizes and thicknesses, which can influence the drying process and the belt’s durability. Selecting a belt that is tailored to the specific needs of the manufacturing process can lead to improved performance and reduced maintenance requirements. Consulting with manufacturers or suppliers can provide valuable insights into the most suitable options available.

In conclusion, the maintenance and longevity of polyester mesh drying belts in manufacturing are influenced by several factors, including regular inspections, cleaning, environmental conditions, proper tension and alignment, and material selection. By prioritizing these aspects, manufacturers can enhance the efficiency of their drying processes while minimizing downtime and replacement costs. Ultimately, investing in the maintenance of polyester mesh drying belts not only extends their lifespan but also contributes to the overall productivity and profitability of industrial operations. As industries continue to evolve, the importance of understanding and implementing effective maintenance strategies for these essential components cannot be overstated.