The Role of Ultipleat High Flow Filters in Oil and Gas Filtration

Benefits of Using Ultipleat High Flow Filters in Oil and Gas Filtration

In the oil and gas industry, filtration is a critical process that ensures the quality and purity of the final product. One of the key components in this process is the use of high flow filters, such as Ultipleat high flow filters. These filters are designed to handle high flow rates while maintaining efficiency and effectiveness in removing contaminants from the fluid. In this article, we will explore the benefits of using Ultipleat high flow filters in oil and gas filtration.

One of the primary benefits of Ultipleat high flow filters is their high flow rate capabilities. These filters are specifically designed to handle large volumes of fluid, making them ideal for applications where high flow rates are required. This high flow rate capability allows for faster filtration processes, reducing downtime and increasing overall efficiency in oil and gas operations.

Additionally, Ultipleat high flow filters are known for their superior filtration efficiency. These filters are designed to remove a wide range of contaminants, including particles, water, and other impurities that can negatively impact the quality of the final product. By using Ultipleat high flow filters, oil and gas companies can ensure that their products meet the required quality standards and regulations.

Another key benefit of Ultipleat high flow filters is their long service life. These filters are built to withstand the harsh conditions often found in oil and gas operations, such as high temperatures, pressure fluctuations, and exposure to corrosive chemicals. This durability ensures that Ultipleat high flow filters can provide reliable filtration performance over an extended period, reducing the need for frequent filter replacements and maintenance.

Furthermore, Ultipleat high flow filters offer a compact and space-saving design. These filters have a smaller footprint compared to traditional filtration systems, making them ideal for applications where space is limited. The compact design of Ultipleat high flow filters also allows for easy installation and maintenance, further enhancing their efficiency and convenience in oil and gas filtration processes.

In addition to their high flow rate capabilities, superior filtration efficiency, long service life, and compact design, Ultipleat high flow filters also offer cost savings for oil and gas companies. By using these filters, companies can reduce operating costs associated with filter replacements, maintenance, and downtime. The efficiency and reliability of Ultipleat high flow filters help to optimize filtration processes, leading to increased productivity and profitability in oil and gas operations.

Overall, Ultipleat high flow filters play a crucial role in oil and gas filtration by providing high flow rate capabilities, superior filtration efficiency, long service life, compact design, and cost savings. These filters are essential components in ensuring the quality and purity of oil and gas products, while also improving operational efficiency and reducing costs for companies in the industry. By incorporating Ultipleat high flow filters into their filtration systems, oil and gas companies can achieve optimal performance and reliability in their operations.

How Ultipleat High Flow Filters Improve Efficiency in Oil and Gas Filtration

In the oil and gas industry, filtration plays a crucial role in ensuring the efficiency and reliability of operations. Contaminants such as dirt, debris, and water can have a detrimental impact on equipment and processes, leading to costly downtime and maintenance. To combat these issues, companies rely on high-quality filtration systems to remove impurities and protect their assets. Ultipleat High Flow Filters are a popular choice for oil and gas filtration due to their superior performance and efficiency.

One of the key advantages of Ultipleat High Flow Filters is their ability to handle high flow rates while maintaining excellent filtration efficiency. These filters are designed to provide a large surface area for filtration, allowing them to capture a high volume of contaminants without sacrificing flow rate. This means that companies can achieve the desired level of filtration without compromising on productivity or throughput.

Additionally, Ultipleat High Flow Filters are known for their durability and longevity. Made from high-quality materials, these filters are designed to withstand the harsh conditions typically found in oil and gas applications. This ensures that they can continue to perform effectively over an extended period, reducing the need for frequent replacements and maintenance.

Another key benefit of Ultipleat High Flow Filters is their ease of installation and maintenance. These filters are designed for quick and simple installation, allowing companies to get up and running with minimal downtime. Additionally, their design makes them easy to clean and maintain, further reducing the overall cost of ownership.

Ultipleat High Flow Filters are also highly versatile, making them suitable for a wide range of oil and gas applications. Whether filtering water for injection, removing contaminants from fuel, or protecting equipment from abrasive particles, these filters can be tailored to meet the specific needs of each application. This flexibility allows companies to achieve optimal filtration performance across their operations.

In addition to their performance and efficiency, Ultipleat High Flow Filters are also environmentally friendly. By removing contaminants from oil and gas streams, these filters help to reduce the environmental impact of operations. This not only benefits the environment but also helps companies comply with regulations and standards related to pollution control.

Overall, Ultipleat High Flow Filters play a crucial role in improving efficiency and reliability in oil and gas filtration. Their superior performance, durability, ease of installation, and versatility make them a popular choice for companies looking to enhance their filtration processes. By investing in high-quality filtration systems like Ultipleat High Flow Filters, companies can protect their equipment, reduce downtime, and achieve optimal performance in their operations.

Case Studies Demonstrating the Effectiveness of Ultipleat High Flow Filters in Oil and Gas Filtration

Oil and gas filtration is a critical process in the industry, as it helps to remove contaminants and impurities from the fluids used in various operations. One of the key components in this process is the use of high-quality filters, such as Ultipleat High Flow Filters. These filters are designed to provide superior performance and efficiency in removing particles and ensuring the cleanliness of the fluids being used.

One of the key advantages of Ultipleat High Flow Filters is their ability to handle high flow rates while maintaining excellent filtration efficiency. This makes them ideal for use in oil and gas applications where large volumes of fluid need to be processed quickly and effectively. In addition, these filters are designed to be durable and long-lasting, reducing the need for frequent replacements and maintenance.

Several case studies have demonstrated the effectiveness of Ultipleat High Flow Filters in oil and gas filtration. In one study, a major oil and gas company implemented these filters in their production process and saw a significant improvement in the quality of their fluids. The filters were able to remove a high percentage of contaminants, resulting in cleaner and more reliable fluids for use in their operations.

Another case study involved a natural gas processing plant that was experiencing issues with contamination in their gas streams. By implementing Ultipleat High Flow Filters, the plant was able to effectively remove impurities and improve the overall quality of their gas output. This led to increased efficiency and reduced downtime, ultimately saving the company time and money.

In a different case study, a drilling company used Ultipleat High Flow Filters in their drilling mud system to remove solid particles and maintain the cleanliness of the fluid. The filters were able to handle the high flow rates and effectively remove contaminants, resulting in improved drilling performance and reduced equipment wear. This allowed the company to complete their drilling operations more efficiently and with fewer disruptions.

Overall, these case studies highlight the importance of using high-quality filters like Ultipleat High Flow Filters in oil and gas filtration. By investing in superior filtration technology, companies can improve the quality of their fluids, reduce downtime, and increase overall efficiency in their operations. With their ability to handle high flow rates and provide excellent filtration efficiency, these filters are a valuable asset for any oil and gas company looking to optimize their filtration processes.

In conclusion, Ultipleat High Flow Filters play a crucial role in oil and gas filtration by providing superior performance and efficiency in removing contaminants from fluids. Through various case studies, the effectiveness of these filters has been demonstrated in improving the quality of fluids, reducing downtime, and increasing overall efficiency in oil and gas operations. By investing in high-quality filters like Ultipleat High Flow Filters, companies can ensure the cleanliness and reliability of their fluids, ultimately leading to improved performance and cost savings in the long run.

Future Trends and Innovations in Ultipleat High Flow Filters for Oil and Gas Filtration

The oil and gas industry plays a crucial role in powering the global economy. However, the extraction and processing of oil and gas come with their own set of challenges, one of which is the need for effective filtration systems to ensure the purity and quality of the final product. Ultipleat high flow filters have emerged as a key technology in oil and gas filtration, offering superior performance and efficiency compared to traditional filtration methods.

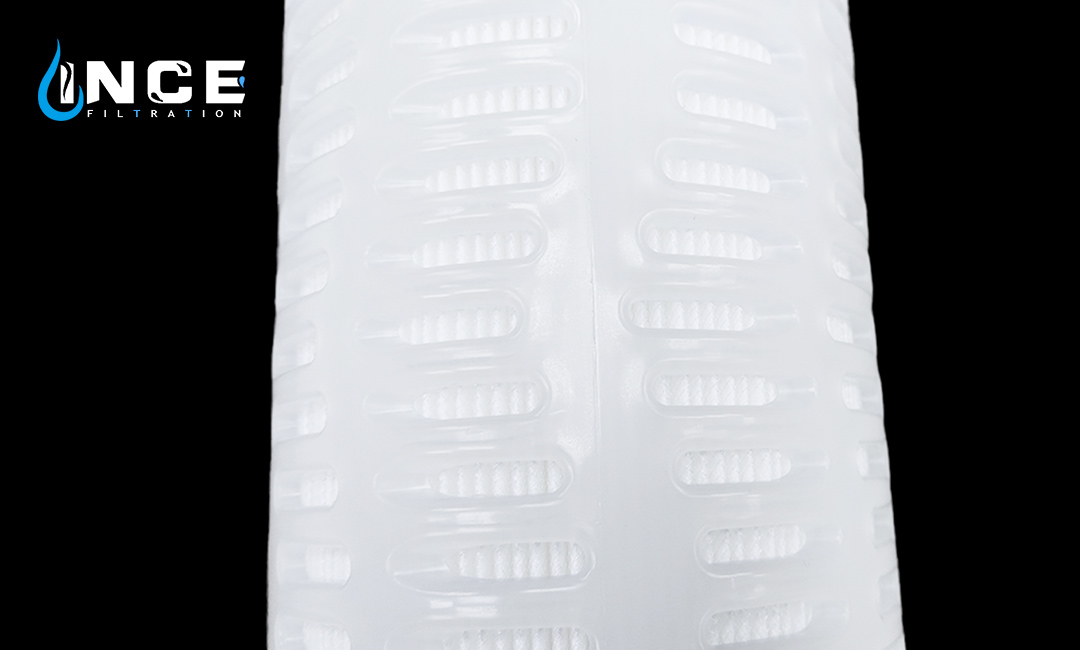

Ultipleat high flow filters are designed to handle high flow rates while maintaining excellent filtration efficiency. These filters are capable of removing contaminants such as particulates, water, and other impurities from oil and gas streams, ensuring that the final product meets the required quality standards. The unique design of Ultipleat high flow filters allows for a larger surface area, which results in higher dirt-holding capacity and longer service life.

One of the key advantages of Ultipleat high flow filters is their ability to handle high flow rates without compromising on filtration efficiency. This makes them ideal for use in applications where large volumes of oil and gas need to be processed quickly and efficiently. In addition, Ultipleat high flow filters are designed to be easily replaceable, reducing downtime and maintenance costs for oil and gas operators.

As the oil and gas industry continues to evolve, the demand for more advanced filtration technologies is expected to grow. Ultipleat high flow filters are well-positioned to meet this demand, thanks to their superior performance and efficiency. In recent years, there has been a growing focus on sustainability and environmental responsibility in the oil and gas industry, driving the need for more efficient filtration systems that can help reduce waste and minimize environmental impact.

In response to these trends, manufacturers of Ultipleat high flow filters are constantly innovating and improving their products to meet the evolving needs of the oil and gas industry. One of the key areas of focus for future developments is the use of advanced materials and coatings to enhance the performance and durability of Ultipleat high flow filters. By incorporating new technologies and materials, manufacturers can further improve the efficiency and reliability of these filters, making them even more effective in removing contaminants from oil and gas streams.

Another important trend in the development of Ultipleat high flow filters is the integration of smart technologies and automation. By incorporating sensors and monitoring systems into the filters, operators can track performance in real-time and make adjustments as needed to optimize filtration efficiency. This not only helps improve the overall performance of the filtration system but also reduces the risk of downtime and maintenance issues.

In conclusion, Ultipleat high flow filters play a crucial role in oil and gas filtration, offering superior performance and efficiency compared to traditional filtration methods. As the oil and gas industry continues to evolve, the demand for more advanced filtration technologies is expected to grow, driving the need for innovative solutions that can meet the evolving needs of the industry. By incorporating advanced materials, coatings, and smart technologies, manufacturers of Ultipleat high flow filters are well-positioned to meet these challenges and continue to provide effective filtration solutions for the oil and gas industry.