Top Applications for Spiral Press Filter Belts in Wastewater Treatment

Enhanced Filtration Efficiency in Wastewater Treatment

In the realm of wastewater treatment, the quest for enhanced filtration efficiency is paramount, as it directly impacts the effectiveness of the entire treatment process. One of the most innovative solutions that has emerged in recent years is the use of spiral press filter belts. These specialized belts are designed to optimize the filtration process, ensuring that contaminants are effectively removed from wastewater, thereby improving the overall quality of the treated water. The unique design of spiral press filter belts allows for a continuous and efficient filtration process, which is essential in modern wastewater treatment facilities.

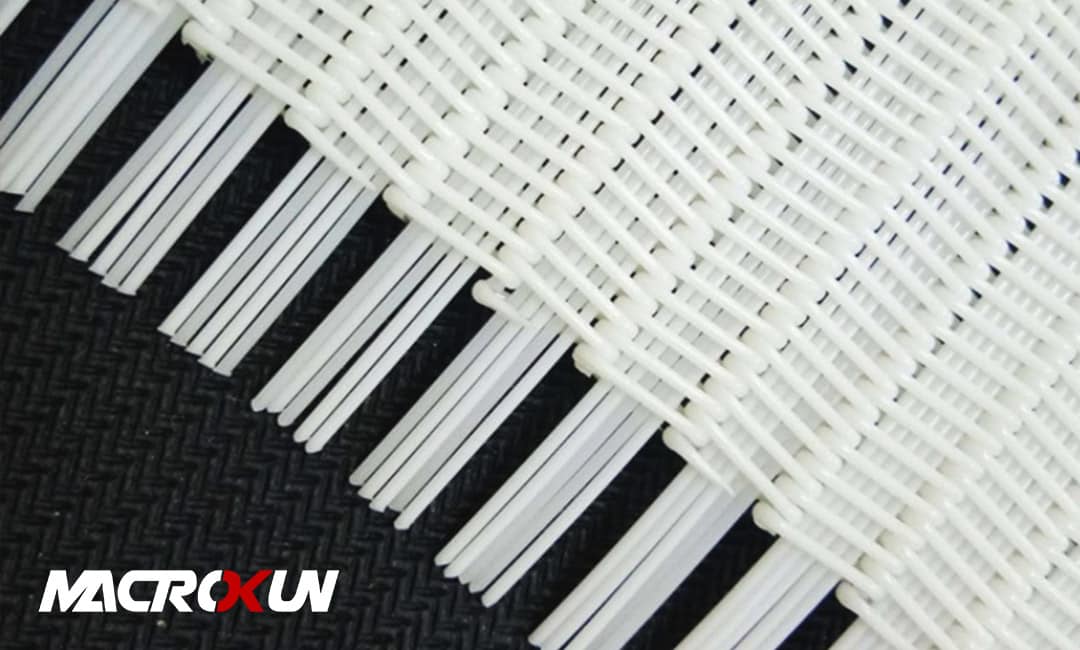

The operational principle of spiral press filter belts is rooted in their ability to provide a large surface area for filtration while maintaining a compact design. This is achieved through the spiral configuration, which not only enhances the flow of wastewater but also facilitates the separation of solids from liquids. As wastewater passes through the belt, the spiral structure allows for a gradual and controlled filtration process, ensuring that even the smallest particles are captured. This is particularly important in applications where the removal of fine solids is critical, such as in the treatment of industrial effluents or municipal wastewater.

Moreover, the materials used in the construction of spiral press filter belts contribute significantly to their performance. Typically made from durable synthetic materials, these belts are resistant to chemical degradation and wear, which is essential in the harsh environments often encountered in wastewater treatment plants. This durability ensures a longer lifespan for the belts, reducing the need for frequent replacements and thereby lowering operational costs. Additionally, the smooth surface of the belts minimizes the risk of clogging, which can be a common issue in traditional filtration systems. This characteristic not only enhances the efficiency of the filtration process but also reduces maintenance requirements, allowing operators to focus on other critical aspects of wastewater treatment.

In addition to their structural advantages, spiral press filter belts also play a crucial role in improving the overall energy efficiency of wastewater treatment processes. By facilitating a more effective separation of solids and liquids, these belts can reduce the energy consumption associated with subsequent treatment stages, such as centrifugation or additional filtration. This energy efficiency is increasingly important as wastewater treatment facilities strive to meet regulatory standards while minimizing their environmental footprint. Consequently, the integration of spiral press filter belts into existing systems can lead to significant operational savings and a more sustainable approach to wastewater management.

Furthermore, the versatility of spiral press filter belts allows them to be employed in various stages of the wastewater treatment process. From primary filtration to sludge dewatering, these belts can adapt to different operational requirements, making them an invaluable asset in diverse treatment scenarios. Their ability to handle varying flow rates and solid concentrations ensures that they can be effectively utilized in both small-scale and large-scale treatment facilities. As the demand for efficient and reliable wastewater treatment solutions continues to grow, the adoption of spiral press filter belts is likely to increase, driven by their proven performance and adaptability.

In conclusion, the application of spiral press filter belts in wastewater treatment represents a significant advancement in filtration technology. By enhancing filtration efficiency, reducing maintenance needs, and promoting energy savings, these belts are transforming the landscape of wastewater management. As facilities seek to improve their operational efficiency and environmental sustainability, the role of spiral press filter belts will undoubtedly become more prominent, paving the way for a cleaner and more efficient future in wastewater treatment.

Cost-Effective Solutions for Municipal Wastewater Management

In the realm of municipal wastewater management, the quest for cost-effective solutions is paramount, particularly as cities grapple with increasing populations and the corresponding rise in wastewater generation. One innovative approach that has gained traction in recent years is the use of spiral press filter belts, which offer a multitude of benefits in the treatment process. These belts, designed for dewatering sludge, play a crucial role in enhancing the efficiency of wastewater treatment facilities while simultaneously reducing operational costs.

To begin with, spiral press filter belts are engineered to optimize the dewatering process, which is a critical step in wastewater treatment. By effectively separating water from solid waste, these belts significantly reduce the volume of sludge that must be processed and disposed of. This reduction not only lowers transportation and disposal costs but also minimizes the environmental impact associated with sludge management. As municipalities strive to adhere to stringent environmental regulations, the adoption of such technologies becomes increasingly essential.

Moreover, the operational efficiency of spiral press filter belts contributes to their cost-effectiveness. These belts are designed to operate continuously, allowing for a steady flow of wastewater through the treatment system. This continuous operation reduces downtime and maintenance costs, which are often significant in traditional dewatering methods. Additionally, the durability of these belts ensures a longer lifespan, further decreasing the need for frequent replacements and associated expenses. Consequently, municipalities can allocate their resources more effectively, channeling funds into other critical areas of infrastructure and service improvement.

In addition to their efficiency and durability, spiral press filter belts are also versatile, making them suitable for various applications within wastewater treatment facilities. They can be utilized in different stages of the treatment process, including primary and secondary sludge dewatering, as well as in the treatment of industrial wastewater. This adaptability allows municipalities to implement a single solution across multiple processes, simplifying operations and reducing the need for multiple types of equipment. As a result, the integration of spiral press filter belts can lead to streamlined operations and enhanced overall performance of wastewater treatment facilities.

Furthermore, the implementation of spiral press filter belts aligns with the growing trend towards sustainability in municipal wastewater management. By reducing the volume of sludge and enhancing the efficiency of the treatment process, these belts contribute to a more sustainable approach to wastewater management. This is particularly important as municipalities face increasing pressure to adopt environmentally friendly practices. The ability to minimize waste and optimize resource use not only benefits the environment but also enhances the public perception of municipal services.

In conclusion, the use of spiral press filter belts in municipal wastewater management presents a compelling case for cost-effective solutions. Their ability to enhance dewatering efficiency, reduce operational costs, and promote sustainability makes them an invaluable asset for wastewater treatment facilities. As municipalities continue to seek innovative ways to manage their wastewater challenges, the adoption of spiral press filter belts will likely play a pivotal role in shaping the future of wastewater treatment. By investing in such technologies, cities can ensure that they are not only meeting current demands but also paving the way for a more sustainable and efficient approach to wastewater management in the years to come.

Innovations in Spiral Press Filter Belt Technology for Industrial Applications

In recent years, the advancements in spiral press filter belt technology have significantly transformed the landscape of wastewater treatment in industrial applications. These innovations have not only enhanced the efficiency of the filtration process but have also contributed to more sustainable practices within various industries. As industries face increasing pressure to comply with stringent environmental regulations, the role of spiral press filter belts has become increasingly vital.

One of the most notable innovations in this field is the development of high-strength, durable materials that enhance the longevity and performance of spiral press filter belts. Traditional materials often succumb to wear and tear, leading to frequent replacements and increased operational costs. However, the introduction of advanced synthetic fibers and composite materials has resulted in belts that can withstand harsh chemical environments and extreme temperatures. This durability not only reduces maintenance downtime but also ensures consistent performance over extended periods, thereby optimizing the overall efficiency of wastewater treatment processes.

Moreover, the design of spiral press filter belts has evolved to incorporate features that improve their functionality. For instance, the integration of varying mesh sizes allows for the effective separation of different types of solids, catering to the specific needs of diverse industrial applications. This adaptability is crucial, as industries such as food processing, pharmaceuticals, and petrochemicals often deal with a wide range of wastewater compositions. By utilizing belts with customizable mesh configurations, facilities can achieve higher filtration rates and better quality effluent, ultimately leading to improved compliance with environmental standards.

In addition to material and design innovations, advancements in manufacturing techniques have also played a significant role in enhancing the performance of spiral press filter belts. The implementation of precision weaving technologies has resulted in belts that exhibit superior structural integrity and uniformity. This precision not only contributes to the belts’ strength but also ensures that they maintain their shape and functionality under varying operational conditions. Consequently, industries can rely on these belts to deliver consistent results, which is essential for maintaining the integrity of wastewater treatment systems.

Furthermore, the integration of smart technologies into spiral press filter belt systems is revolutionizing the way industries monitor and manage their wastewater treatment processes. The incorporation of sensors and IoT devices allows for real-time data collection and analysis, enabling operators to make informed decisions regarding maintenance and operational adjustments. This proactive approach not only enhances the efficiency of the filtration process but also minimizes the risk of unexpected failures, thereby reducing operational costs and improving overall system reliability.

As industries continue to prioritize sustainability, the role of spiral press filter belts in wastewater treatment is expected to expand further. The ability to recover valuable resources from wastewater, such as water and nutrients, aligns with the growing trend of circular economy practices. Innovations in spiral press filter belt technology are paving the way for more efficient resource recovery processes, allowing industries to minimize waste and maximize the reuse of materials.

In conclusion, the ongoing innovations in spiral press filter belt technology are reshaping the wastewater treatment landscape for industrial applications. With advancements in materials, design, manufacturing techniques, and smart technologies, these belts are becoming indispensable tools for achieving efficient and sustainable wastewater management. As industries strive to meet environmental regulations and embrace sustainable practices, the significance of spiral press filter belts will undoubtedly continue to grow, driving further innovations in this critical area.