Top Benefits of Using Spiral Fabric Belts for Filtration

Enhanced Filtration Efficiency

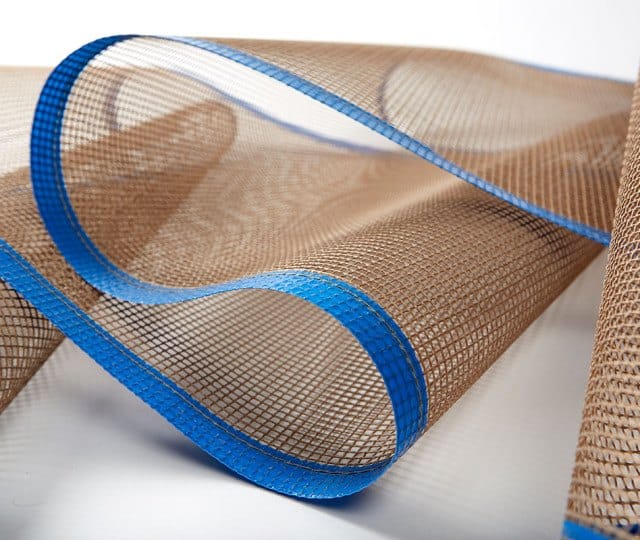

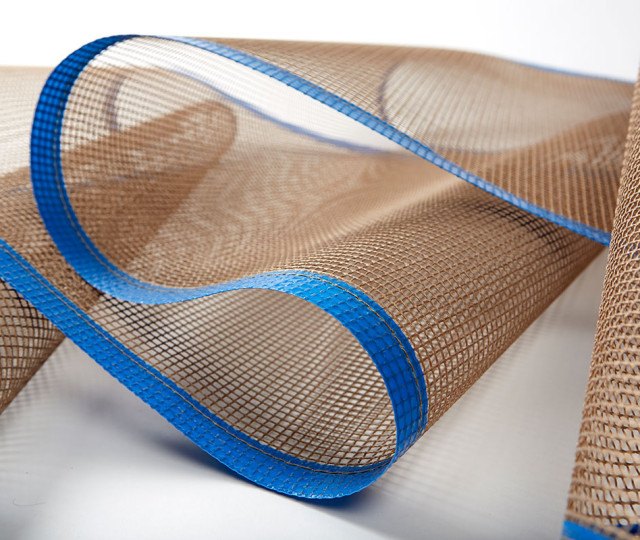

Spiral fabric belts are a popular choice for filtration applications due to their numerous benefits. These belts are made from high-quality materials such as polyester, polypropylene, or nylon, which make them durable and long-lasting. One of the top benefits of using spiral fabric belts for filtration is their enhanced filtration efficiency.

When it comes to filtration, efficiency is key. Spiral fabric belts are designed to provide a large surface area for filtration, allowing for better particle retention and separation. This means that these belts can effectively remove impurities and contaminants from liquids or gases, resulting in cleaner and purer end products.

In addition to their high filtration efficiency, spiral fabric belts are also known for their excellent cake release properties. The spiral design of these belts allows for easy cake release, preventing clogging and ensuring continuous operation. This is especially important in industries where downtime is costly and productivity is crucial.

Furthermore, spiral fabric belts are easy to clean and maintain, making them a cost-effective filtration solution. These belts can be easily washed or cleaned using water or other cleaning agents, prolonging their lifespan and ensuring optimal performance. This not only saves time and money but also reduces the environmental impact of filtration processes.

Another benefit of using spiral fabric belts for filtration is their versatility. These belts can be customized to meet specific filtration requirements, making them suitable for a wide range of applications. Whether you need to filter water, chemicals, food products, or pharmaceuticals, spiral fabric belts can be tailored to suit your needs.

Moreover, spiral fabric belts are resistant to chemicals, abrasion, and high temperatures, making them ideal for demanding filtration environments. These belts can withstand harsh conditions without compromising their filtration efficiency, ensuring reliable and consistent performance.

In conclusion, spiral fabric belts offer a range of benefits that make them an excellent choice for filtration applications. From enhanced filtration efficiency to easy maintenance and versatility, these belts provide a cost-effective and reliable solution for industries that require efficient particle separation and removal. Whether you are filtering liquids or gases, spiral fabric belts can help you achieve cleaner and purer end products while maximizing productivity and minimizing downtime.

Durability and Longevity

Spiral fabric belts have emerged as a preferred choice in various filtration applications due to their remarkable durability and longevity. These belts are engineered to withstand the rigors of demanding environments, making them an ideal solution for industries that require reliable filtration systems. One of the primary benefits of spiral fabric belts is their ability to resist wear and tear, which is crucial in maintaining operational efficiency. Unlike traditional filtration media, which may degrade over time, spiral fabric belts are constructed from high-quality materials that provide enhanced resistance to abrasion and chemical exposure. This characteristic not only extends the lifespan of the belts but also reduces the frequency of replacements, leading to significant cost savings for businesses.

Moreover, the design of spiral fabric belts contributes to their durability. The unique spiral construction allows for a more uniform distribution of stress across the belt surface, minimizing the risk of localized damage. This design feature is particularly beneficial in applications where the belts are subjected to heavy loads or continuous movement. As a result, users can expect consistent performance over extended periods, which is essential for maintaining the integrity of the filtration process. Additionally, the flexibility of these belts enables them to adapt to various operational conditions without compromising their structural integrity. This adaptability is a key factor in their longevity, as it allows the belts to perform effectively in diverse environments, from high-temperature settings to those involving corrosive substances.

Another significant advantage of spiral fabric belts is their resistance to environmental factors. In many industrial settings, belts are exposed to moisture, temperature fluctuations, and other challenging conditions that can lead to premature failure. However, spiral fabric belts are designed to withstand such adversities, ensuring that they remain functional even in the most demanding situations. This resilience not only enhances their lifespan but also contributes to the overall reliability of the filtration system. Users can have confidence in the performance of spiral fabric belts, knowing that they are engineered to endure the challenges posed by their specific applications.

Furthermore, the maintenance requirements for spiral fabric belts are relatively low compared to other filtration options. Their robust construction means that they are less prone to damage, which translates to fewer maintenance interventions. This aspect is particularly advantageous for industries that prioritize operational efficiency and seek to minimize downtime. By reducing the need for frequent repairs or replacements, businesses can allocate resources more effectively, ultimately leading to improved productivity.

In addition to their durability, spiral fabric belts also offer excellent filtration capabilities. The design allows for optimal flow rates while effectively capturing particles, ensuring that the filtration process remains efficient over time. This combination of durability and performance makes spiral fabric belts a valuable investment for companies looking to enhance their filtration systems. As industries continue to evolve and face new challenges, the demand for reliable and long-lasting filtration solutions will only increase. Spiral fabric belts stand out as a solution that not only meets these demands but also provides long-term benefits that contribute to the overall success of filtration operations.

In conclusion, the durability and longevity of spiral fabric belts make them an exceptional choice for filtration applications. Their resistance to wear, adaptability to various conditions, and low maintenance requirements position them as a reliable option for industries seeking to optimize their filtration processes. As businesses strive for efficiency and cost-effectiveness, the advantages offered by spiral fabric belts will undoubtedly play a crucial role in shaping the future of filtration technology.

Cost-Effectiveness in Operations

Spiral fabric belts are a popular choice for filtration in various industries due to their numerous benefits. One of the top advantages of using spiral fabric belts for filtration is their cost-effectiveness in operations. These belts are designed to be durable and long-lasting, which helps reduce maintenance and replacement costs over time.

In addition to their durability, spiral fabric belts are also known for their efficiency in filtration. These belts are designed to provide a high level of filtration, ensuring that particles and contaminants are effectively removed from the process stream. This can help improve the overall quality of the end product and reduce the risk of contamination.

Another key benefit of using spiral fabric belts for filtration is their versatility. These belts can be customized to meet the specific needs of different industries and applications. Whether you are filtering water, chemicals, or food products, spiral fabric belts can be tailored to provide the optimal filtration solution for your operation.

Furthermore, spiral fabric belts are easy to install and maintain, which can help reduce downtime and increase productivity. These belts are designed to be user-friendly, allowing for quick and efficient installation and maintenance. This can help streamline operations and ensure that your filtration system is always running at peak performance.

Additionally, spiral fabric belts are environmentally friendly, making them a sustainable choice for filtration. These belts are made from high-quality materials that are designed to be recyclable and eco-friendly. By choosing spiral fabric belts for filtration, you can reduce your environmental impact and contribute to a more sustainable future.

Overall, the cost-effectiveness of using spiral fabric belts for filtration makes them a top choice for many industries. These belts offer a range of benefits, including durability, efficiency, versatility, ease of installation and maintenance, and environmental sustainability. By investing in spiral fabric belts for your filtration needs, you can improve the quality of your end product, reduce maintenance costs, and contribute to a more sustainable operation.