Top Features of Polyester Belts for Advanced Filtration Systems

Durability and Strength of Polyester Belts

Polyester belts are a popular choice for advanced filtration systems due to their durability and strength. These belts are made from polyester fibers, which are known for their high tensile strength and resistance to abrasion. In this article, we will explore the top features of polyester belts that make them ideal for use in filtration systems.

One of the key features of polyester belts is their exceptional durability. These belts are designed to withstand the harsh conditions of industrial filtration systems, including high temperatures, corrosive chemicals, and heavy loads. Polyester fibers are inherently strong and resistant to wear and tear, making them an excellent choice for applications where reliability is crucial.

In addition to their durability, polyester belts are also known for their high tensile strength. This means that they can withstand a significant amount of tension without breaking or stretching. This is important in filtration systems, where belts are often subjected to high levels of stress as they move through the system. Polyester belts can handle this stress with ease, ensuring that they will not fail prematurely.

Another key feature of polyester belts is their resistance to abrasion. Polyester fibers are naturally resistant to abrasion, which means that they can maintain their integrity even when subjected to rough handling or contact with abrasive materials. This makes polyester belts an excellent choice for applications where wear and tear are common, such as in mining or wastewater treatment facilities.

Polyester belts are also known for their low stretch properties. Unlike some other types of belts, polyester belts do not stretch significantly under tension. This means that they will maintain their shape and size over time, ensuring consistent performance in filtration systems. This low stretch property also makes polyester belts easier to install and maintain, as they do not require frequent adjustments to maintain proper tension.

In addition to their durability and strength, polyester belts are also highly resistant to chemicals. Polyester fibers are naturally resistant to many common chemicals, including acids, bases, and solvents. This makes polyester belts an excellent choice for applications where exposure to chemicals is a concern, such as in chemical processing plants or wastewater treatment facilities.

Overall, polyester belts offer a combination of durability, strength, and chemical resistance that make them an ideal choice for advanced filtration systems. Their high tensile strength, resistance to abrasion, low stretch properties, and chemical resistance make them a reliable and long-lasting option for a wide range of applications. Whether you are looking for a belt for a mining operation, a chemical processing plant, or a wastewater treatment facility, polyester belts are sure to meet your needs.

Resistance to Chemicals and Abrasion

Polyester belts have emerged as a vital component in advanced filtration systems, particularly due to their remarkable resistance to chemicals and abrasion. This resistance is crucial in environments where belts are exposed to harsh substances and mechanical wear. The chemical resistance of polyester is primarily attributed to its molecular structure, which allows it to withstand a wide range of acids, bases, and solvents without degrading. This characteristic is particularly beneficial in industrial applications where exposure to corrosive materials is common. For instance, in wastewater treatment facilities, polyester belts can effectively handle the aggressive nature of various chemicals used in the treatment process, ensuring longevity and reliability.

Moreover, the abrasion resistance of polyester belts significantly enhances their performance in filtration systems. In many applications, belts are subjected to constant friction and wear as they transport materials. The durability of polyester minimizes the risk of wear and tear, which can lead to costly downtimes and maintenance. This durability is not only a matter of material strength but also relates to the design and construction of the belts. High-quality polyester belts are often engineered with reinforced fibers that provide additional strength, allowing them to maintain their integrity even under challenging conditions.

In addition to their chemical and abrasion resistance, polyester belts offer excellent dimensional stability. This stability is essential for maintaining the precise alignment and tension required in filtration systems. When belts stretch or deform, it can lead to inefficiencies in the filtration process, resulting in subpar performance. Polyester’s ability to retain its shape under varying loads and temperatures ensures that filtration systems operate smoothly and effectively. This characteristic is particularly important in applications where consistent performance is critical, such as in food processing or pharmaceuticals, where contamination risks must be minimized.

Furthermore, the lightweight nature of polyester belts contributes to their efficiency in filtration systems. Lighter belts reduce the overall load on the machinery, which can lead to lower energy consumption and reduced wear on other components. This aspect not only enhances the operational efficiency of the filtration system but also contributes to a more sustainable approach by minimizing energy usage. As industries increasingly focus on sustainability, the lightweight and durable nature of polyester belts aligns well with these goals.

Another significant advantage of polyester belts is their versatility. They can be manufactured in various thicknesses, widths, and lengths, making them suitable for a wide range of filtration applications. This adaptability allows engineers and designers to customize solutions that meet specific operational requirements, ensuring optimal performance in diverse environments. Whether in a high-volume industrial setting or a specialized laboratory application, polyester belts can be tailored to fit the unique demands of the filtration process.

In conclusion, the resistance to chemicals and abrasion offered by polyester belts makes them an indispensable choice for advanced filtration systems. Their ability to withstand harsh environments, combined with their durability, dimensional stability, and lightweight nature, positions them as a superior option in various applications. As industries continue to evolve and face new challenges, the role of polyester belts in enhancing filtration efficiency and reliability will undoubtedly become even more prominent. By investing in high-quality polyester belts, organizations can ensure that their filtration systems remain effective, sustainable, and capable of meeting the demands of modern operations.

Enhanced Flexibility and Performance in Filtration Systems

Polyester belts have emerged as a pivotal component in advanced filtration systems, offering a range of features that significantly enhance flexibility and performance. One of the most notable characteristics of polyester is its inherent flexibility, which allows these belts to adapt seamlessly to various operational conditions. This adaptability is crucial in filtration applications where the flow of materials can vary widely. The ability of polyester belts to bend and conform to different shapes without compromising their structural integrity ensures that they can maintain optimal performance even in challenging environments.

Moreover, the lightweight nature of polyester contributes to its effectiveness in filtration systems. This reduced weight not only facilitates easier handling and installation but also minimizes the energy required for operation. As a result, systems utilizing polyester belts can achieve higher efficiency levels, leading to lower operational costs. The combination of flexibility and lightweight properties allows for smoother transitions and movements within the filtration process, which is essential for maintaining consistent flow rates and preventing blockages.

In addition to flexibility and weight, polyester belts exhibit excellent resistance to various chemicals and environmental factors. This resistance is particularly important in filtration systems that deal with aggressive substances or fluctuating temperatures. The durability of polyester ensures that the belts can withstand harsh conditions without degrading, thereby extending their lifespan and reducing the need for frequent replacements. This longevity not only enhances the overall reliability of the filtration system but also contributes to cost savings over time.

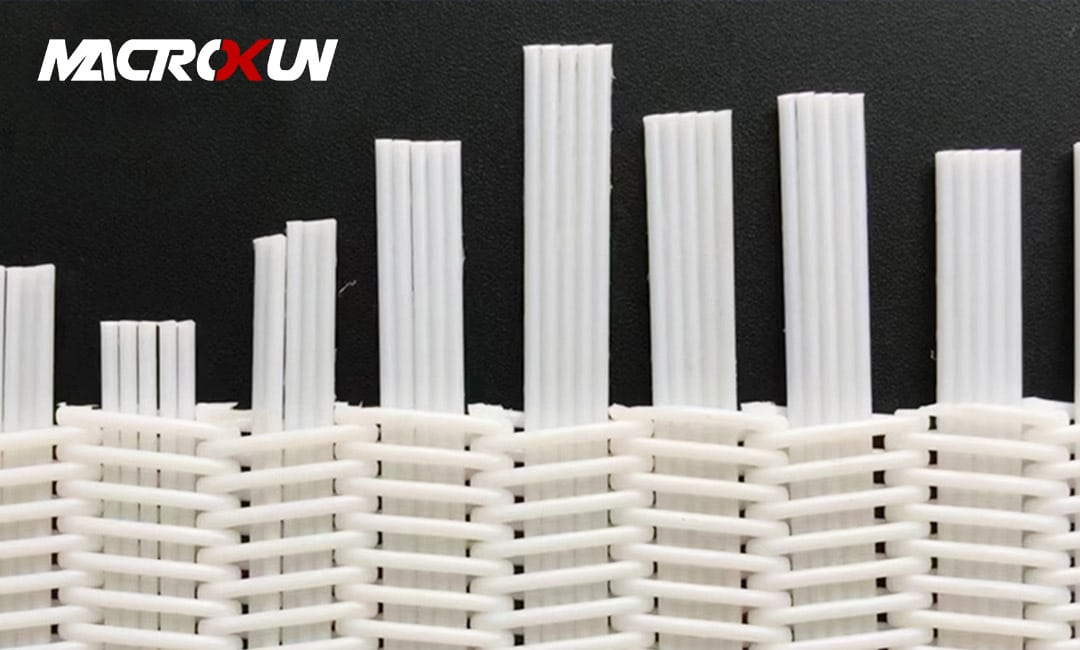

Another significant feature of polyester belts is their ability to provide superior filtration performance. The material’s fine weave structure allows for precise filtration, effectively capturing particles of varying sizes. This capability is essential in applications where maintaining high levels of purity is critical, such as in the food and beverage industry or in water treatment facilities. The efficiency of polyester belts in trapping contaminants ensures that the end product meets stringent quality standards, thereby enhancing the overall effectiveness of the filtration system.

Furthermore, polyester belts are designed to operate effectively across a wide range of temperatures and humidity levels. This versatility makes them suitable for diverse applications, from industrial processes to environmental management. The ability to perform consistently under varying conditions is a testament to the advanced engineering behind polyester belt technology. As industries continue to evolve and demand more from their filtration systems, the adaptability of polyester belts positions them as a reliable choice for meeting these challenges.

The ease of maintenance associated with polyester belts also contributes to their appeal in filtration systems. Regular cleaning and upkeep are essential for maintaining optimal performance, and polyester belts can be easily cleaned without the risk of damage. This feature not only simplifies maintenance procedures but also ensures that the belts can continue to perform at their best over time. By reducing downtime associated with maintenance, polyester belts help to enhance the overall efficiency of filtration systems.

In conclusion, the top features of polyester belts, including their enhanced flexibility, lightweight nature, chemical resistance, superior filtration performance, and ease of maintenance, make them an ideal choice for advanced filtration systems. As industries increasingly prioritize efficiency and reliability, the role of polyester belts in optimizing filtration processes cannot be overstated. Their ability to adapt to various conditions while maintaining high performance levels positions them as a critical component in the pursuit of effective and sustainable filtration solutions.