Top Features of Polyester Sludge Press Belts for Industrial Use

Benefits of Using Polyester Sludge Press Belts in Industrial Applications

Polyester sludge press belts have emerged as a vital component in various industrial applications, particularly in the wastewater treatment and sludge dewatering processes. These belts are designed to enhance efficiency and effectiveness in the removal of excess water from sludge, thereby facilitating a more manageable and environmentally friendly disposal process. One of the primary benefits of using polyester sludge press belts is their exceptional strength and durability. Made from high-quality polyester fibers, these belts can withstand the rigorous demands of industrial environments, including exposure to harsh chemicals and extreme temperatures. This resilience ensures a longer lifespan, reducing the need for frequent replacements and ultimately lowering operational costs.

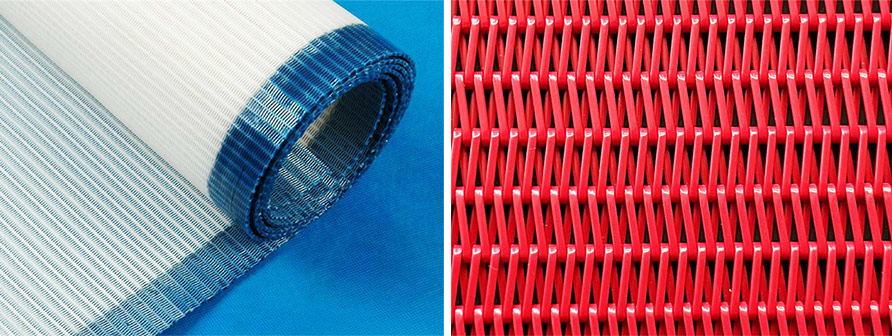

In addition to their durability, polyester sludge press belts offer excellent filtration capabilities. The unique weave of the fabric allows for optimal drainage while retaining solid particles, which is crucial in the dewatering process. This characteristic not only improves the efficiency of sludge removal but also enhances the quality of the final product. As a result, industries can achieve better compliance with environmental regulations, as the treated sludge is more suitable for disposal or further processing. Furthermore, the lightweight nature of polyester belts contributes to their ease of handling and installation. This feature simplifies maintenance procedures, allowing for quicker belt changes and reducing downtime in production processes. Consequently, industries can maintain a steady workflow, which is essential for meeting production targets and ensuring operational efficiency.

Another significant advantage of polyester sludge press belts is their resistance to wear and tear. In industrial settings, belts are often subjected to abrasive materials and high-pressure conditions. Polyester belts are engineered to resist such challenges, ensuring consistent performance over time. This durability translates into fewer operational disruptions and a more reliable sludge dewatering process. Moreover, the smooth surface of polyester belts minimizes friction, which not only enhances the efficiency of the dewatering process but also reduces energy consumption. This energy efficiency is particularly beneficial for industries looking to lower their carbon footprint and operational expenses.

The versatility of polyester sludge press belts is also noteworthy. They can be customized to meet specific application requirements, including variations in thickness, width, and permeability. This adaptability allows industries to select the most suitable belt for their unique processes, ensuring optimal performance. Additionally, polyester belts can be used in various industrial sectors, including food processing, pharmaceuticals, and chemical manufacturing, making them a valuable asset across multiple applications.

Furthermore, the ease of cleaning polyester sludge press belts contributes to their appeal in industrial settings. Regular maintenance is essential for ensuring the longevity and effectiveness of any equipment, and polyester belts can be cleaned efficiently without compromising their structural integrity. This feature not only saves time but also helps maintain hygiene standards, particularly in industries where cleanliness is paramount.

In conclusion, the benefits of using polyester sludge press belts in industrial applications are manifold. Their strength, durability, and excellent filtration capabilities make them an ideal choice for sludge dewatering processes. The lightweight design and resistance to wear enhance operational efficiency, while their versatility allows for customization to meet specific needs. Additionally, the ease of maintenance and cleaning further solidifies their position as a preferred option in various industries. As industries continue to seek ways to improve efficiency and reduce environmental impact, polyester sludge press belts will undoubtedly play a crucial role in achieving these objectives.

How Polyester Sludge Press Belts Improve Efficiency in Sludge Dewatering Processes

Polyester sludge press belts have emerged as a vital component in the industrial sector, particularly in the realm of sludge dewatering processes. These belts are specifically designed to enhance the efficiency of sludge management, which is crucial for various industries, including wastewater treatment, food processing, and chemical manufacturing. One of the primary advantages of polyester sludge press belts is their ability to facilitate the removal of excess water from sludge, thereby reducing its volume and weight. This reduction is significant, as it not only lowers transportation costs but also minimizes the environmental impact associated with sludge disposal.

The unique properties of polyester contribute to the effectiveness of these belts in dewatering applications. Polyester is known for its high tensile strength and durability, which allows the belts to withstand the rigorous conditions often encountered in sludge processing. This resilience ensures that the belts maintain their structural integrity over time, leading to consistent performance and reduced downtime for maintenance or replacement. Furthermore, the smooth surface of polyester belts promotes efficient drainage, allowing water to escape quickly while retaining the solid particles within the sludge. This characteristic is essential for achieving optimal dewatering results, as it directly influences the moisture content of the final product.

In addition to their physical properties, polyester sludge press belts are designed with specific features that enhance their functionality. For instance, many of these belts incorporate a unique weave pattern that maximizes filtration efficiency. This design not only improves the dewatering process but also helps in the separation of solids from liquids, resulting in a cleaner and more manageable sludge cake. The ability to produce a drier sludge cake is particularly beneficial for industries that require the disposal of sludge in a more environmentally friendly manner, as it reduces the volume of waste that must be treated or landfilled.

Moreover, the versatility of polyester sludge press belts allows them to be used in various applications, making them a preferred choice for many industrial operations. Whether in a municipal wastewater treatment facility or a large-scale food processing plant, these belts can be tailored to meet specific operational requirements. This adaptability is further enhanced by the availability of different thicknesses and widths, enabling industries to select the most suitable belt for their unique dewatering needs.

Another significant aspect of polyester sludge press belts is their resistance to chemical degradation. In many industrial settings, sludge can contain a variety of corrosive substances that can compromise the integrity of standard materials. However, polyester belts are engineered to withstand exposure to such chemicals, ensuring longevity and reliability in challenging environments. This resistance not only extends the lifespan of the belts but also contributes to the overall efficiency of the sludge dewatering process, as operators can rely on consistent performance without the need for frequent replacements.

In conclusion, polyester sludge press belts play a crucial role in improving the efficiency of sludge dewatering processes across various industries. Their unique properties, including high tensile strength, effective drainage capabilities, and resistance to chemical degradation, make them an ideal choice for managing sludge effectively. By facilitating the removal of excess water and producing a drier sludge cake, these belts not only enhance operational efficiency but also contribute to more sustainable waste management practices. As industries continue to seek innovative solutions for sludge management, polyester sludge press belts will undoubtedly remain at the forefront of this essential process.

Maintenance Tips for Extending the Lifespan of Polyester Sludge Press Belts

Polyester sludge press belts are essential components in various industrial applications, particularly in wastewater treatment and sludge dewatering processes. These belts are designed to withstand harsh conditions while effectively separating water from sludge, thereby enhancing the efficiency of the dewatering process. However, like any industrial equipment, the longevity and performance of polyester sludge press belts can be significantly influenced by proper maintenance practices. By implementing a few key maintenance tips, operators can extend the lifespan of these belts, ensuring optimal performance and reducing the need for frequent replacements.

One of the primary maintenance tips involves regular cleaning of the belts. Over time, sludge and other contaminants can accumulate on the surface of the belts, leading to reduced efficiency and potential damage. It is advisable to establish a routine cleaning schedule that includes the use of appropriate cleaning agents that are compatible with polyester materials. High-pressure water jets can be effective in removing stubborn residues, but care must be taken to avoid damaging the belt fibers. Additionally, operators should inspect the belts for any signs of wear or damage during the cleaning process, allowing for timely repairs or replacements.

Another crucial aspect of maintenance is monitoring the operating conditions of the sludge press. Factors such as temperature, pressure, and chemical exposure can significantly impact the performance and durability of polyester sludge press belts. Operators should ensure that the belts are not subjected to extreme temperatures or aggressive chemicals that could degrade the material. Implementing temperature and pressure controls can help maintain optimal operating conditions, thereby prolonging the life of the belts. Furthermore, it is essential to regularly check the alignment and tension of the belts during operation. Misalignment or improper tension can lead to uneven wear and tear, ultimately resulting in premature failure.

In addition to these preventive measures, it is beneficial to keep a detailed maintenance log for each polyester sludge press belt. This log should include information on cleaning schedules, inspections, repairs, and any incidents of wear or damage. By maintaining a comprehensive record, operators can identify patterns or recurring issues that may indicate underlying problems with the equipment or operating conditions. This proactive approach not only aids in timely maintenance but also facilitates better decision-making regarding the replacement of belts when necessary.

Moreover, training personnel on the proper handling and maintenance of polyester sludge press belts is vital. Employees should be educated about the specific requirements and best practices for maintaining these belts, including the importance of avoiding sharp objects that could cause cuts or abrasions. Regular training sessions can help reinforce these practices and ensure that all team members are aware of their roles in maintaining the equipment.

Lastly, it is advisable to consult with manufacturers or suppliers for specific maintenance recommendations tailored to the particular type of polyester sludge press belt in use. Manufacturers often provide valuable insights into the best practices for care and maintenance, as well as information on compatible cleaning agents and repair techniques. By following these guidelines and maintaining open communication with suppliers, operators can ensure that they are utilizing the best strategies for extending the lifespan of their polyester sludge press belts.

In conclusion, the maintenance of polyester sludge press belts is a critical factor in ensuring their longevity and performance in industrial applications. By implementing regular cleaning, monitoring operating conditions, maintaining detailed logs, training personnel, and consulting with manufacturers, operators can significantly enhance the durability of these essential components. Ultimately, a proactive maintenance approach not only improves efficiency but also contributes to cost savings by reducing the frequency of replacements.