Why Spiral Fabric Is a Top Choice for Industrial Filtration Systems

Superior Filtration Efficiency

Industrial filtration systems play a crucial role in various industries, from manufacturing to wastewater treatment. These systems are designed to remove impurities and contaminants from liquids and gases, ensuring that the final product meets quality standards. One key component of these filtration systems is the filter media, which is responsible for capturing and retaining particles of different sizes. When it comes to filter media, spiral fabric stands out as a top choice for industrial applications due to its superior filtration efficiency.

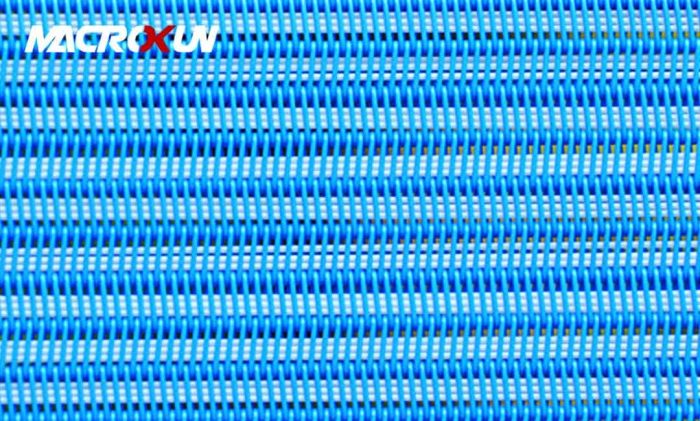

Spiral fabric, also known as spiral link fabric or spiral belt, is a type of filter media made from polyester or polypropylene monofilaments. The unique spiral design of this fabric allows for a high surface area, which enhances its filtration efficiency. The spiral structure also provides excellent mechanical strength, making it suitable for high-pressure applications. Additionally, spiral fabric is resistant to chemicals and abrasion, ensuring a long service life in harsh industrial environments.

One of the key advantages of spiral fabric is its ability to capture particles of various sizes. The tight weave of the fabric prevents larger particles from passing through, while the small gaps between the filaments trap smaller particles. This dual filtration mechanism ensures that the filtrate is free from contaminants, meeting the required purity standards. As a result, industries such as food and beverage, pharmaceuticals, and chemicals rely on spiral fabric for their filtration needs.

Another benefit of spiral fabric is its high flow rate. The open structure of the fabric allows for efficient liquid or gas flow, minimizing pressure drop across the filter media. This not only improves the overall performance of the filtration system but also reduces energy consumption. In industries where large volumes of liquids or gases need to be processed, such as water treatment plants or petrochemical refineries, spiral fabric offers a cost-effective solution for filtration.

In addition to its filtration efficiency and flow rate, spiral fabric is also easy to clean and maintain. The smooth surface of the fabric prevents particles from sticking, making it easier to remove accumulated debris during cleaning cycles. This not only prolongs the service life of the filter media but also ensures consistent filtration performance over time. Industries that require frequent filter changes or maintenance will benefit from the durability and ease of use of spiral fabric.

Overall, spiral fabric is a top choice for industrial filtration systems due to its superior filtration efficiency, high flow rate, and ease of maintenance. Its unique spiral design provides a large surface area for capturing particles of different sizes, while its mechanical strength and chemical resistance make it suitable for a wide range of applications. Whether it’s removing impurities from water, separating solids from liquids, or purifying gases, spiral fabric delivers reliable and efficient filtration performance. For industries that prioritize quality, efficiency, and cost-effectiveness in their filtration processes, spiral fabric is the ideal choice.

Durability and Longevity

Industrial filtration systems play a crucial role in various industries, from manufacturing to wastewater treatment. These systems are designed to remove impurities and contaminants from liquids and gases, ensuring that the final product meets quality standards. One key component of these filtration systems is the filter media, which is responsible for capturing and retaining particles. When it comes to filter media, spiral fabric stands out as a top choice for industrial applications due to its durability and longevity.

Spiral fabric, also known as spiral link fabric or spiral belt, is a type of filter media made from polyester or polypropylene monofilaments. These monofilaments are woven together in a spiral pattern, creating a strong and flexible fabric that is ideal for use in industrial filtration systems. One of the main advantages of spiral fabric is its durability. The spiral structure of the fabric provides excellent tensile strength, allowing it to withstand high pressures and mechanical stresses without tearing or breaking. This makes spiral fabric an ideal choice for applications where the filter media is subjected to heavy loads or abrasive materials.

In addition to its durability, spiral fabric is also known for its longevity. Unlike some other types of filter media that may degrade or deteriorate over time, spiral fabric is highly resistant to wear and tear. The smooth surface of the fabric prevents particles from becoming trapped in the weave, reducing the risk of clogging and extending the lifespan of the filter media. This means that industrial filtration systems equipped with spiral fabric can operate efficiently for extended periods without the need for frequent maintenance or replacement.

Furthermore, spiral fabric is easy to clean and maintain, further contributing to its longevity. The smooth surface of the fabric allows for easy removal of trapped particles and contaminants, ensuring that the filter media remains effective over time. Regular cleaning and maintenance can help prolong the lifespan of spiral fabric, making it a cost-effective choice for industrial filtration systems.

Another key advantage of spiral fabric is its versatility. This type of filter media is available in a wide range of mesh sizes and configurations, making it suitable for a variety of filtration applications. Whether filtering large particles in wastewater treatment or capturing fine particles in chemical processing, spiral fabric can be tailored to meet the specific requirements of different industries. This versatility makes spiral fabric a popular choice among manufacturers and engineers looking for a reliable and efficient filter media for their industrial filtration systems.

In conclusion, spiral fabric is a top choice for industrial filtration systems due to its durability and longevity. The strong and flexible structure of spiral fabric ensures that it can withstand high pressures and mechanical stresses, making it ideal for demanding industrial applications. Additionally, the smooth surface of the fabric prevents clogging and allows for easy cleaning and maintenance, prolonging its lifespan and reducing operating costs. With its versatility and reliability, spiral fabric continues to be a preferred filter media for a wide range of industries seeking efficient and effective filtration solutions.

Cost-Effectiveness

Spiral fabric has emerged as a leading material in the realm of industrial filtration systems, particularly due to its cost-effectiveness. In an era where operational efficiency and budget constraints are paramount, industries are increasingly seeking solutions that not only meet their filtration needs but also align with their financial objectives. The unique properties of spiral fabric make it an attractive option for various applications, allowing companies to achieve significant savings without compromising on performance.

One of the primary reasons spiral fabric is considered cost-effective is its durability. Unlike traditional filtration materials, which may require frequent replacements, spiral fabric is designed to withstand harsh conditions and prolonged use. This longevity translates into lower maintenance costs and reduced downtime, as businesses do not need to frequently halt operations for filter changes. Consequently, the initial investment in spiral fabric can yield substantial long-term savings, making it a wise choice for industries that rely heavily on continuous processes.

Moreover, the manufacturing process of spiral fabric is inherently efficient. The production techniques employed often result in lower energy consumption and reduced waste, which not only benefits the environment but also contributes to lower overall costs. By minimizing the resources required for production, manufacturers can offer spiral fabric at competitive prices, further enhancing its appeal to cost-conscious businesses. This efficiency in production is complemented by the fabric’s ability to be customized for specific filtration needs, allowing companies to optimize their systems without incurring excessive costs.

In addition to its durability and efficient production, spiral fabric offers excellent filtration performance. The unique spiral design allows for a larger surface area, which enhances the fabric’s ability to capture particles and contaminants. This increased efficiency means that businesses can achieve their desired filtration levels with fewer materials, leading to further cost savings. By reducing the amount of fabric needed for effective filtration, companies can allocate their resources more effectively, ultimately improving their bottom line.

Furthermore, the versatility of spiral fabric cannot be overlooked. It can be utilized in a wide range of applications, from water treatment to air filtration, making it a multifaceted solution for various industries. This adaptability means that companies can invest in a single type of filtration material that meets multiple needs, rather than purchasing different materials for different applications. Such consolidation not only simplifies inventory management but also reduces procurement costs, as businesses can negotiate better pricing for bulk purchases.

Another aspect contributing to the cost-effectiveness of spiral fabric is its ease of installation and maintenance. The lightweight nature of the fabric allows for straightforward handling and installation, reducing labor costs associated with setup. Additionally, the maintenance of spiral fabric systems is often less labor-intensive compared to traditional filtration systems, which can require specialized knowledge and tools. This simplicity in both installation and maintenance further enhances the overall cost-effectiveness of spiral fabric as a filtration solution.

In conclusion, the cost-effectiveness of spiral fabric in industrial filtration systems is a result of its durability, efficient production, superior filtration performance, versatility, and ease of maintenance. As industries continue to seek ways to optimize their operations while managing costs, spiral fabric stands out as a top choice that meets both financial and operational needs. By investing in this innovative material, companies can not only enhance their filtration processes but also achieve significant savings, making it a prudent decision in today’s competitive market.