1 Micron Filter Bag for Liquids: Ideal for Precision Filtration

Benefits of Using 1 Micron Filter Bags for Liquid Filtration

The use of 1 micron filter bags for liquid filtration has gained significant attention in various industries due to their ability to provide precise filtration solutions. One of the primary benefits of employing these filter bags is their exceptional capacity to remove fine particles and contaminants from liquids. With a filtration rating of 1 micron, these bags can effectively capture a wide range of impurities, including sediment, dirt, and even some bacteria, thereby ensuring that the final product is of high quality and free from unwanted substances. This level of filtration is particularly crucial in sectors such as pharmaceuticals, food and beverage, and water treatment, where the purity of liquids is paramount.

Moreover, the efficiency of 1 micron filter bags contributes to improved operational performance. By utilizing these bags, businesses can reduce the frequency of equipment maintenance and downtime caused by clogging and contamination. When liquids are filtered through a 1 micron bag, the risk of particles entering machinery is significantly minimized, leading to enhanced longevity and reliability of pumps and other processing equipment. Consequently, this not only saves time and resources but also increases overall productivity, allowing companies to focus on their core operations without the constant worry of filtration-related issues.

In addition to operational benefits, the use of 1 micron filter bags can also lead to cost savings. While the initial investment in high-quality filter bags may be higher than that of coarser alternatives, the long-term advantages often outweigh these costs. The ability to maintain cleaner liquids means that downstream processes can operate more efficiently, reducing the need for additional filtration stages or chemical treatments. Furthermore, the extended lifespan of equipment due to reduced wear and tear translates into lower maintenance costs over time. Thus, businesses can achieve a more favorable return on investment by integrating 1 micron filter bags into their filtration systems.

Another significant advantage of these filter bags is their versatility. They can be utilized in a variety of applications, ranging from industrial processes to laboratory settings. Whether it is for filtering water, oils, or other liquids, 1 micron filter bags can adapt to different environments and requirements. This adaptability makes them an invaluable asset for companies that deal with multiple types of liquids or that require specific filtration standards. Additionally, the availability of various materials, such as polypropylene, polyester, and nylon, allows users to select the most suitable option based on the chemical compatibility and temperature requirements of their specific applications.

Furthermore, the environmental impact of using 1 micron filter bags should not be overlooked. By ensuring that liquids are free from harmful contaminants, these bags contribute to the production of cleaner, safer products. This is particularly important in industries where environmental regulations are stringent, as compliance with these regulations can be achieved more easily with effective filtration solutions. As companies increasingly prioritize sustainability, the role of efficient filtration systems becomes even more critical in minimizing waste and promoting responsible practices.

In conclusion, the benefits of using 1 micron filter bags for liquid filtration are manifold. From enhancing operational efficiency and reducing costs to providing versatility and supporting environmental sustainability, these filter bags represent a smart choice for industries that demand precision and reliability in their filtration processes. As the need for high-quality liquid products continues to grow, the adoption of advanced filtration technologies, such as 1 micron filter bags, will undoubtedly play a pivotal role in meeting these demands.

Applications of 1 Micron Filter Bags in Various Industries

1 micron filter bags have emerged as a crucial component in various industries, serving as an effective solution for precision filtration. Their ability to capture particles as small as one micron makes them indispensable in applications where purity and clarity are paramount. In the food and beverage industry, for instance, these filter bags are widely utilized to ensure that liquids such as juices, wines, and oils are free from contaminants. The filtration process not only enhances the quality of the final product but also extends shelf life by removing impurities that could lead to spoilage. As consumers increasingly demand higher standards of cleanliness and safety, the role of 1 micron filter bags in this sector becomes even more significant.

In the pharmaceutical industry, the need for stringent filtration processes is even more pronounced. Here, 1 micron filter bags are employed to ensure that solutions used in drug manufacturing are devoid of particulates that could compromise product integrity. The precision offered by these filter bags is essential in maintaining compliance with regulatory standards, which often dictate the maximum allowable levels of contaminants in pharmaceutical products. By utilizing 1 micron filter bags, manufacturers can achieve the high levels of purity required for both active ingredients and final formulations, thereby safeguarding patient health and ensuring the efficacy of medications.

Moreover, the chemical processing industry also benefits from the use of 1 micron filter bags. In this sector, the filtration of various liquids, including solvents and reactants, is critical to maintaining operational efficiency and product quality. The presence of particulates can lead to equipment wear and tear, resulting in costly downtime and maintenance. By implementing 1 micron filter bags in their processes, chemical manufacturers can effectively remove unwanted solids, thereby protecting their machinery and ensuring a smoother production flow. This not only enhances productivity but also contributes to a safer working environment by minimizing the risk of contamination.

In addition to these industries, the water treatment sector has found significant applications for 1 micron filter bags. As water quality standards become increasingly stringent, the need for effective filtration solutions has grown. These filter bags are utilized in various stages of water treatment, including pre-filtration and final polishing, to remove suspended solids, algae, and other contaminants. By ensuring that treated water meets regulatory requirements, 1 micron filter bags play a vital role in public health and environmental protection. Their effectiveness in capturing fine particles makes them an essential tool for municipalities and industries alike, striving to provide clean and safe water.

Furthermore, the electronics industry also relies on 1 micron filter bags during the manufacturing of sensitive components. In this context, the presence of even the smallest particles can lead to defects in electronic devices. Therefore, the use of precision filtration is critical to maintaining the integrity of production processes. By incorporating 1 micron filter bags, manufacturers can ensure that their products meet the high standards required for performance and reliability.

In conclusion, the applications of 1 micron filter bags span a wide range of industries, each benefiting from the precision and effectiveness these filtration solutions provide. From food and beverage to pharmaceuticals, chemicals, water treatment, and electronics, the ability to remove fine particulates is essential for maintaining product quality, safety, and compliance with regulatory standards. As industries continue to evolve and demand higher levels of purity, the importance of 1 micron filter bags will undoubtedly grow, solidifying their role as a cornerstone of precision filtration.

How to Choose the Right 1 Micron Filter Bag for Your Needs

When it comes to selecting the appropriate 1 micron filter bag for liquid filtration, several factors must be considered to ensure optimal performance and efficiency. The first step in this process is to identify the specific application for which the filter bag will be used. Different industries, such as food and beverage, pharmaceuticals, and water treatment, have unique requirements that dictate the type of filter bag needed. For instance, in the food and beverage sector, it is crucial to choose filter bags that comply with health and safety regulations, ensuring that the materials used do not leach harmful substances into the liquids being filtered.

Once the application is established, the next consideration is the type of liquid being filtered. Various liquids possess different viscosities, temperatures, and chemical compositions, all of which can influence the choice of filter bag material. For example, if the liquid is highly viscous or contains abrasive particles, a filter bag made from durable materials such as polypropylene or polyester may be more suitable. These materials not only provide the necessary strength but also offer resistance to chemical degradation, ensuring longevity and reliability during the filtration process.

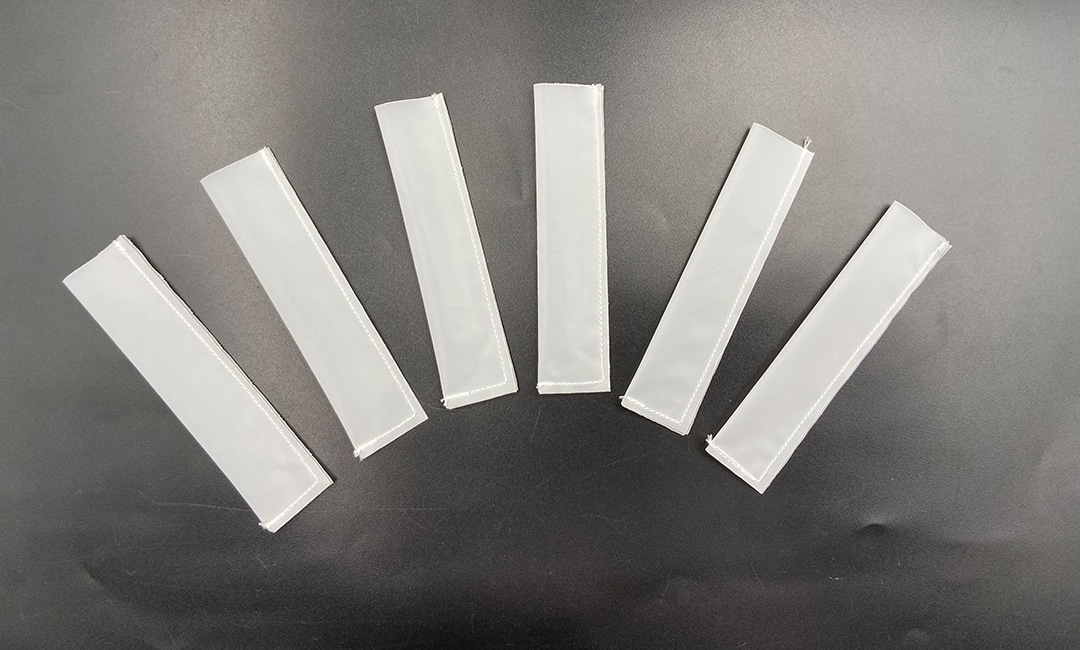

In addition to material selection, the design of the filter bag plays a significant role in its effectiveness. Filter bags come in various designs, including flat, pleated, and tubular configurations. Each design has its advantages and is suited for specific applications. For instance, pleated filter bags typically offer a larger surface area, which can enhance filtration efficiency and extend the time between bag replacements. Conversely, flat filter bags may be more appropriate for applications requiring a straightforward filtration process without the need for high flow rates.

Moreover, it is essential to consider the flow rate required for your application. The flow rate will determine the size and number of filter bags needed to achieve the desired filtration efficiency. A higher flow rate may necessitate multiple filter bags or larger-sized bags to prevent clogging and ensure consistent performance. Therefore, understanding the flow dynamics of your system is crucial in making an informed decision.

Another important aspect to evaluate is the compatibility of the filter bag with the filtration system. Different systems may have specific requirements regarding the size and shape of the filter bag, as well as the method of attachment. Ensuring that the filter bag fits securely within the system will prevent leaks and maintain the integrity of the filtration process. Additionally, it is advisable to consult with the manufacturer or supplier to obtain recommendations tailored to your specific filtration system.

Finally, cost considerations should not be overlooked. While it may be tempting to opt for the least expensive option, it is vital to balance cost with quality and performance. Investing in a high-quality 1 micron filter bag can lead to improved filtration efficiency, reduced downtime, and lower overall operational costs in the long run. Therefore, conducting thorough research and possibly seeking expert advice can help in making a well-informed decision.

In conclusion, choosing the right 1 micron filter bag for liquid filtration involves a careful assessment of various factors, including application requirements, liquid characteristics, filter bag design, flow rate, system compatibility, and cost. By taking the time to evaluate these elements, one can ensure that the selected filter bag meets the specific needs of the filtration process, ultimately leading to enhanced performance and efficiency.

Maintenance Tips for Extending the Life of 1 Micron Filter Bags

1 Micron Filter Bag for Liquids: Ideal for Precision Filtration

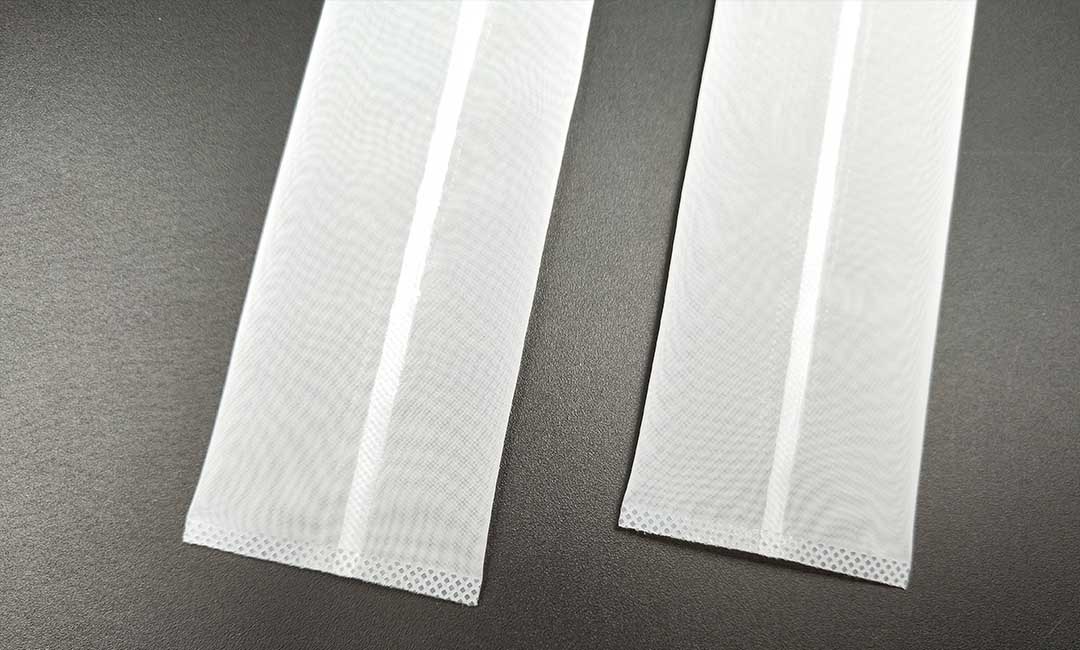

When it comes to liquid filtration, precision is key. Whether you are filtering water, chemicals, or other liquids, having the right filter bag can make all the difference. A 1 micron filter bag is ideal for applications that require fine filtration and removal of small particles. These filter bags are designed to capture particles as small as 1 micron in size, ensuring that your liquid is free from contaminants and impurities.

One of the key benefits of using a 1 micron filter bag is its ability to provide high levels of filtration efficiency. By capturing particles as small as 1 micron, these filter bags can effectively remove even the tiniest impurities from your liquid. This is especially important in industries where product purity is crucial, such as pharmaceuticals, food and beverage, and electronics manufacturing.

In order to ensure that your 1 micron filter bag continues to perform at its best, it is important to follow some maintenance tips to extend its life. Proper maintenance not only helps to maximize the lifespan of the filter bag but also ensures that it continues to provide optimal filtration efficiency.

One of the most important maintenance tips for extending the life of a 1 micron filter bag is to regularly inspect and clean the filter bag. Over time, particles and contaminants can build up on the surface of the filter bag, reducing its effectiveness. By inspecting the filter bag regularly and cleaning it as needed, you can prevent clogs and ensure that it continues to filter efficiently.

Another important maintenance tip is to replace the filter bag when necessary. While 1 micron filter bags are designed to be durable and long-lasting, they will eventually reach the end of their lifespan. It is important to monitor the condition of the filter bag and replace it when it becomes worn or damaged. By replacing the filter bag in a timely manner, you can prevent contaminants from bypassing the filter and entering your liquid.

In addition to regular inspection and replacement, it is also important to handle the filter bag with care. Avoid rough handling or excessive pressure, as this can damage the filter bag and reduce its effectiveness. When installing or removing the filter bag, take care to follow the manufacturer’s instructions and handle it gently to avoid tears or punctures.

Proper storage is another key factor in maintaining the life of a 1 micron filter bag. Store the filter bag in a clean, dry environment away from direct sunlight and extreme temperatures. This will help to prevent degradation of the filter bag material and ensure that it remains in optimal condition for use.

By following these maintenance tips, you can extend the life of your 1 micron filter bag and ensure that it continues to provide high levels of filtration efficiency. Proper maintenance not only helps to protect your liquid from contaminants but also helps to maximize the lifespan of your filter bag, saving you time and money in the long run. With the right care and attention, your 1 micron filter bag can continue to deliver precision filtration for your liquid applications.