160 Micron Rosin Industries Press Bag – Maximum Filtration & Yield

Benefits of Using 160 Micron Rosin Press Bags

Rosin extraction has become increasingly popular in the cannabis industry as a solventless method for producing high-quality concentrates. One essential tool for achieving optimal results in rosin extraction is the use of rosin press bags. These bags are designed to contain the material being pressed while allowing the rosin to flow out, resulting in a cleaner and more efficient extraction process.

One of the key factors to consider when choosing a rosin press bag is the micron size. The micron size refers to the size of the mesh screen in the bag, which determines the level of filtration during the extraction process. A 160 micron rosin press bag is a popular choice among rosin enthusiasts due to its ability to provide maximum filtration and yield.

When using a 160 micron rosin press bag, the material being pressed is contained within the bag, allowing the rosin to flow out while trapping any plant material or contaminants. This results in a cleaner and purer final product, with minimal impurities. The 160 micron size is ideal for extracting rosin from a variety of materials, including flower, kief, and hash.

In addition to providing superior filtration, a 160 micron rosin press bag also helps to maximize yield during the extraction process. By containing the material being pressed, the bag ensures that all of the rosin is captured and collected, resulting in a higher overall yield. This is especially important for commercial operations where maximizing efficiency and output is crucial.

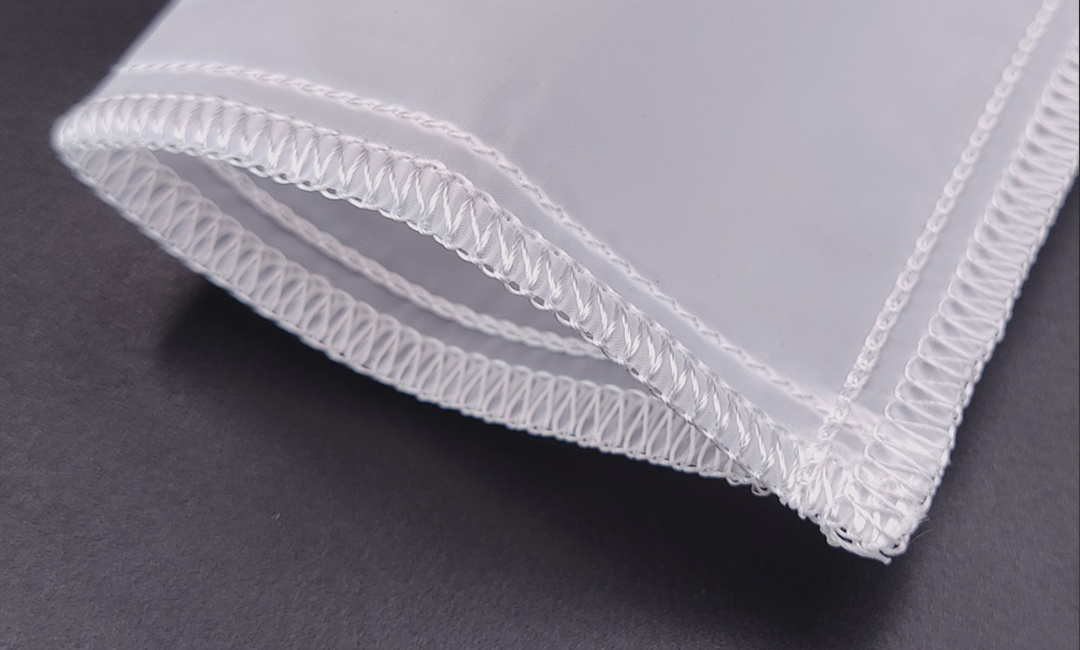

Another benefit of using a 160 micron rosin press bag is its durability and longevity. These bags are made from high-quality materials that can withstand the pressure and heat of the extraction process, ensuring that they can be used multiple times without tearing or breaking. This not only saves money in the long run but also reduces waste and environmental impact.

Furthermore, a 160 micron rosin press bag is easy to use and clean, making it a convenient option for both beginners and experienced extractors. Simply fill the bag with the material to be pressed, place it in the press, and apply heat and pressure to extract the rosin. After use, the bag can be easily cleaned with isopropyl alcohol or warm water, ready to be used again for the next extraction.

In conclusion, the benefits of using a 160 micron rosin press bag are clear. From maximum filtration and yield to durability and ease of use, these bags offer a superior extraction experience for rosin enthusiasts of all levels. Whether you are a home extractor looking to improve your process or a commercial operation seeking to maximize efficiency, a 160 micron rosin press bag is a valuable tool that can help you achieve the best results in your rosin extraction endeavors.

How to Maximize Yield with 160 Micron Filtration

Maximizing yield in the extraction process is a critical concern for producers seeking to optimize their output while maintaining the quality of their final product. One effective method to achieve this is through the use of 160 micron rosin press bags, which are specifically designed to enhance filtration and yield. The micron size of the bag plays a pivotal role in determining the efficiency of the extraction process, as it directly influences the amount of plant material that can pass through while retaining the desirable compounds.

To begin with, understanding the significance of micron size is essential. A 160 micron bag strikes a balance between allowing sufficient oil to flow through while filtering out unwanted plant material, such as chlorophyll and other impurities. This size is particularly advantageous for those working with high-quality flower, as it enables the extraction of a more refined product. By utilizing a 160 micron bag, producers can ensure that they are capturing the maximum amount of essential oils and terpenes, which are crucial for the flavor and aroma of the final product.

Moreover, the choice of starting material is equally important in maximizing yield. High-quality, well-cured flower will yield better results than lower-grade material. When using a 160 micron bag, it is advisable to select buds that are dense and rich in resin. This not only enhances the extraction process but also ensures that the final product is potent and flavorful. Additionally, proper preparation of the material before pressing can significantly impact yield. Grinding the flower to a consistent size allows for more even extraction, ensuring that the maximum amount of oil is released during the pressing process.

Furthermore, the pressing technique employed can also influence yield. It is crucial to apply the right amount of pressure and heat during extraction. Too much pressure can lead to the extraction of undesirable compounds, while too little may result in a lower yield. A temperature range of 180 to 220 degrees Fahrenheit is generally recommended for optimal extraction with a 160 micron bag. This range allows for the effective release of oils without compromising the integrity of the terpenes. By carefully monitoring these variables, producers can fine-tune their process to achieve the best possible yield.

In addition to these technical considerations, timing plays a vital role in maximizing yield. The duration of the pressing process should be carefully managed to ensure that the material is not over-pressed, which can lead to a decrease in quality. A pressing time of 30 to 90 seconds is often ideal, depending on the specific material and desired outcome. By experimenting with different pressing times, producers can identify the sweet spot that yields the highest quality product.

Finally, it is essential to maintain cleanliness throughout the extraction process. Residue from previous extractions can contaminate the current batch, leading to a decrease in yield and quality. Regularly cleaning the press and using fresh bags for each extraction will help ensure that the final product is pure and potent.

In conclusion, maximizing yield with a 160 micron rosin press bag involves a combination of selecting high-quality starting material, employing effective pressing techniques, and maintaining a clean workspace. By paying attention to these factors, producers can significantly enhance their extraction process, resulting in a higher yield of premium rosin that meets the demands of discerning consumers.

Comparing 160 Micron Rosin Bags to Other Sizes

When it comes to extracting rosin from your favorite herbs or flowers, using the right filtration bag can make all the difference in the quality and yield of your final product. One popular option among rosin enthusiasts is the 160 micron rosin bag, known for its ability to provide maximum filtration and yield during the extraction process. In this article, we will compare the 160 micron rosin bag to other sizes to help you understand why it is a preferred choice for many in the industry.

First and foremost, let’s discuss the importance of filtration when it comes to rosin extraction. Filtration bags are essential in the process as they help to separate the plant material from the desired rosin, ensuring a clean and pure final product. The size of the micron bag you choose will determine the level of filtration, with smaller micron sizes providing finer filtration and larger micron sizes allowing more material to pass through.

The 160 micron rosin bag falls in the middle range of filtration sizes, making it a versatile option for a variety of extraction needs. It offers a good balance between filtration and yield, allowing for a clean extraction while still maximizing the amount of rosin collected. This makes it a popular choice among those who value both quality and quantity in their rosin production.

In comparison, smaller micron bags such as 90 or 120 microns provide even finer filtration but may result in a lower yield due to the smaller pore size. While these bags are great for producing high-quality rosin, they may not be as efficient for those looking to maximize their yield. On the other hand, larger micron bags like 190 or 220 microns allow more material to pass through, resulting in a higher yield but potentially sacrificing some of the purity of the final product.

The 160 micron rosin bag strikes a perfect balance between these extremes, offering a good compromise between filtration and yield. It allows for a clean extraction while still ensuring a decent amount of rosin is collected, making it a versatile option for a wide range of extraction needs. Whether you are a home enthusiast looking to produce small batches of high-quality rosin or a commercial producer looking to maximize your yield, the 160 micron bag is a reliable choice.

In conclusion, the 160 micron rosin bag is a popular choice in the industry for its ability to provide maximum filtration and yield during the extraction process. It offers a good balance between filtration and yield, making it a versatile option for a variety of extraction needs. While smaller micron bags may provide finer filtration and larger micron bags may offer higher yields, the 160 micron bag strikes a perfect balance between the two, making it a preferred choice for many in the rosin industry. Whether you are a beginner or an experienced extractor, the 160 micron rosin bag is a reliable option that can help you achieve the quality and quantity of rosin you desire.

Best Practices for Using 160 Micron Press Bags in Extraction

When it comes to extracting rosin, using the right press bag can make a significant difference in both the quality and quantity of your yield. One popular choice among rosin enthusiasts is the 160 micron press bag, known for its ability to provide maximum filtration and yield. In this article, we will explore the best practices for using 160 micron press bags in extraction to help you achieve the best results possible.

First and foremost, it is important to understand the purpose of using a press bag in rosin extraction. Press bags are designed to contain the material being pressed while allowing the rosin to flow through the micron screen. The 160 micron size is ideal for rosin extraction as it strikes a balance between filtration and yield. The smaller micron size helps to filter out plant material and contaminants, resulting in a cleaner and purer final product.

When using a 160 micron press bag, it is crucial to properly prepare your material before pressing. Make sure to break down your material into small, uniform pieces to ensure even distribution and maximum surface area for extraction. This will help to optimize the extraction process and improve the overall yield of your rosin.

Once your material is prepared, carefully fill the 160 micron press bag with the desired amount of material. Be sure not to overfill the bag, as this can lead to uneven pressure distribution during pressing. It is recommended to leave some space at the top of the bag to allow for expansion during the pressing process.

When it comes to pressing, it is essential to use the right amount of pressure and heat to achieve optimal results. The ideal temperature for pressing rosin is typically between 180-220 degrees Fahrenheit, depending on the material being used. It is important to monitor the temperature closely to prevent overheating and degradation of the material.

In terms of pressure, it is recommended to start with a lower pressure and gradually increase as needed. Applying too much pressure too quickly can result in blowouts and lower yields. It is best to press slowly and evenly to ensure a consistent extraction process.

During the pressing process, it is important to monitor the flow of rosin from the press bag. A steady flow of rosin indicates that the extraction is going smoothly, while a slow or uneven flow may indicate issues with pressure or temperature. Adjust as needed to achieve the desired results.

After pressing, carefully remove the press bag from the heat source and allow it to cool before handling. Once cooled, carefully open the press bag and collect the extracted rosin. It is recommended to use a tool such as a dabber or scraper to collect the rosin and transfer it to a storage container.

In conclusion, using a 160 micron press bag in rosin extraction can help to maximize filtration and yield, resulting in a cleaner and more potent final product. By following the best practices outlined in this article, you can achieve optimal results and enjoy the full benefits of using a high-quality press bag in your extraction process.