A Beginner’s Guide to High Flow Cartridges for Industrial Applications

Benefits of High Flow Cartridges in Industrial Applications

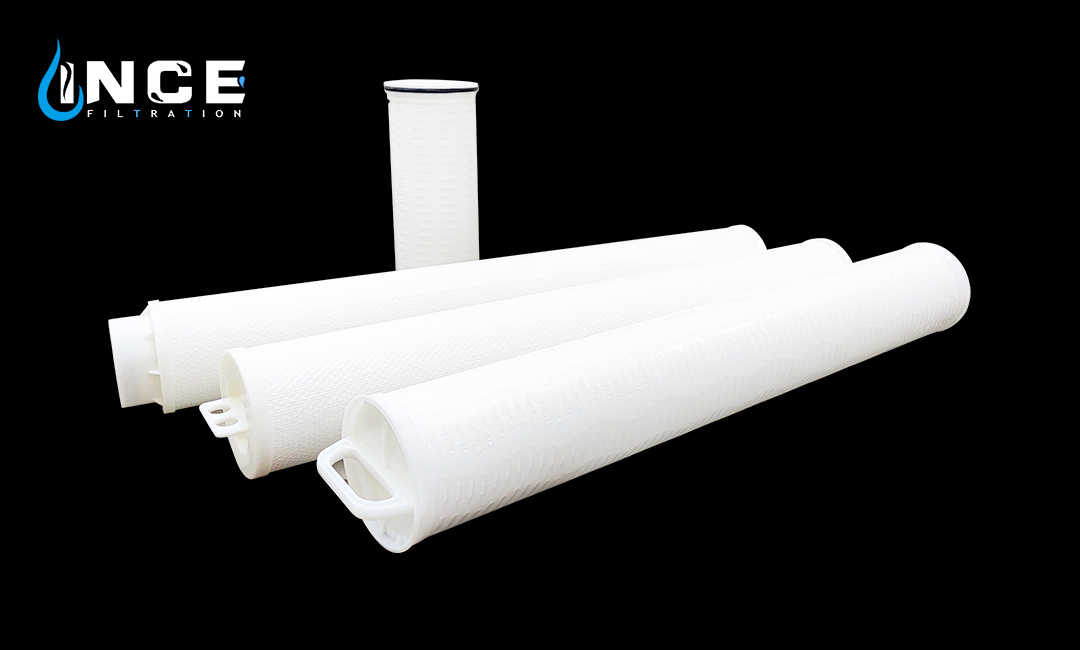

High flow cartridges are an essential component in many industrial applications, providing a reliable and efficient way to filter liquids and gases. These cartridges offer numerous benefits that make them a popular choice for industries such as manufacturing, petrochemical, and food processing. In this article, we will explore the advantages of high flow cartridges and why they are a valuable investment for industrial applications.

One of the primary benefits of high flow cartridges is their ability to handle large volumes of fluid or gas at a high flow rate. This makes them ideal for applications where a high flow rate is required, such as in large-scale manufacturing processes or industrial filtration systems. High flow cartridges can process significantly more liquid or gas than standard cartridges, reducing the need for multiple cartridges and increasing overall efficiency.

In addition to their high flow rate capabilities, high flow cartridges are also known for their superior filtration performance. These cartridges are designed to remove contaminants and impurities from liquids and gases, ensuring that the final product meets strict quality standards. The advanced filtration technology used in high flow cartridges allows for efficient particle removal, resulting in cleaner and purer fluids.

Another key benefit of high flow cartridges is their long service life and durability. These cartridges are built to withstand the rigors of industrial applications, with robust construction and high-quality materials that ensure reliable performance over an extended period. This durability reduces maintenance costs and downtime, making high flow cartridges a cost-effective solution for industrial filtration needs.

Furthermore, high flow cartridges are easy to install and replace, minimizing downtime and ensuring continuous operation. Their simple design and compatibility with standard filtration systems make them a convenient choice for industrial applications. With quick and easy installation, high flow cartridges can be seamlessly integrated into existing filtration systems, providing immediate benefits to the operation.

High flow cartridges also offer versatility in terms of compatibility with different fluids and gases. These cartridges are available in a variety of materials and configurations to suit specific application requirements, ensuring optimal performance and efficiency. Whether filtering water, chemicals, or gases, high flow cartridges can be customized to meet the unique needs of each industrial application.

Overall, high flow cartridges provide a range of benefits that make them an essential component in industrial filtration systems. From their high flow rate capabilities to superior filtration performance and long service life, these cartridges offer a reliable and efficient solution for a wide range of industrial applications. With easy installation and compatibility with various fluids and gases, high flow cartridges are a valuable investment for industries looking to improve their filtration processes and enhance overall efficiency.

How to Choose the Right High Flow Cartridge for Your Needs

High flow cartridges are essential components in industrial applications where large volumes of liquid need to be filtered quickly and efficiently. These cartridges are designed to handle high flow rates while maintaining the same level of filtration performance as standard cartridges. If you are new to the world of high flow cartridges, choosing the right one for your specific needs can be a daunting task. In this article, we will provide you with a beginner’s guide to high flow cartridges for industrial applications, helping you make an informed decision when selecting the right cartridge for your filtration system.

When choosing a high flow cartridge, the first thing you need to consider is the type of filtration media that will best suit your application. High flow cartridges are available in a variety of media options, including pleated, depth, and membrane filters. Pleated filters are ideal for applications where high dirt-holding capacity is required, while depth filters are better suited for applications where high flow rates are a priority. Membrane filters, on the other hand, are designed for applications that require the removal of fine particles and microorganisms.

Another important factor to consider when choosing a high flow cartridge is the micron rating of the filter. The micron rating indicates the size of particles that the filter can effectively remove from the liquid. For industrial applications, it is crucial to select a high flow cartridge with the appropriate micron rating to ensure that the filtered liquid meets the required quality standards. It is recommended to consult with a filtration expert to determine the optimal micron rating for your specific application.

In addition to the filtration media and micron rating, the size and configuration of the high flow cartridge are also important considerations. High flow cartridges come in various sizes and configurations to accommodate different flow rates and installation requirements. It is essential to select a cartridge size that is compatible with your filtration system and can handle the desired flow rate without compromising filtration performance. Additionally, consider the configuration of the cartridge, such as end caps and gaskets, to ensure a proper fit and seal within your filtration system.

Furthermore, when choosing a high flow cartridge, it is essential to consider the compatibility of the cartridge with the liquid being filtered. Some liquids may be corrosive or abrasive, requiring a high flow cartridge with specialized materials or coatings to withstand the harsh conditions. It is crucial to select a cartridge that is chemically compatible with the liquid to prevent degradation and ensure long-term performance.

In conclusion, selecting the right high flow cartridge for your industrial application requires careful consideration of various factors, including filtration media, micron rating, size, configuration, and compatibility with the liquid being filtered. By understanding these key factors and consulting with filtration experts, you can make an informed decision when choosing a high flow cartridge that meets your specific needs and ensures optimal filtration performance. Remember, investing in the right high flow cartridge is essential for maintaining the efficiency and reliability of your filtration system in industrial applications.

Installation and Maintenance Tips for High Flow Cartridges

High flow cartridges are essential components in industrial applications where large volumes of liquid need to be filtered quickly and efficiently. These cartridges are designed to handle high flow rates, making them ideal for use in processes that require a high level of filtration. However, installing and maintaining high flow cartridges can be a bit more complex than standard cartridges due to their size and flow capacity. In this article, we will provide some tips for installing and maintaining high flow cartridges to ensure optimal performance and longevity.

When it comes to installing high flow cartridges, the first step is to carefully read the manufacturer’s instructions. These instructions will provide important information on how to properly install the cartridge, including any specific tools or equipment that may be required. It is important to follow these instructions closely to ensure that the cartridge is installed correctly and functions as intended.

Before installing the high flow cartridge, it is important to inspect the housing to ensure that it is clean and free of any debris. Any dirt or debris in the housing can affect the performance of the cartridge and may lead to premature clogging. If necessary, clean the housing thoroughly before installing the cartridge to ensure optimal filtration efficiency.

Once the housing is clean, carefully insert the high flow cartridge into the housing, making sure that it is properly aligned and seated securely. It is important to ensure that the cartridge is installed in the correct orientation to prevent any leaks or bypassing of unfiltered liquid. Once the cartridge is in place, secure the housing according to the manufacturer’s instructions to prevent any movement or shifting during operation.

After the high flow cartridge is installed, it is important to regularly monitor its performance to ensure that it is functioning properly. This can be done by checking the pressure drop across the cartridge, which is a measure of how well the cartridge is filtering the liquid. A sudden increase in pressure drop may indicate that the cartridge is becoming clogged and needs to be replaced.

In addition to monitoring the pressure drop, it is also important to regularly inspect the cartridge for any signs of damage or wear. This can include cracks, tears, or other visible defects that may affect the performance of the cartridge. If any damage is found, the cartridge should be replaced immediately to prevent any contamination of the filtered liquid.

In conclusion, high flow cartridges are essential components in industrial applications that require efficient filtration of large volumes of liquid. By following the manufacturer’s instructions for installation and regularly monitoring the performance of the cartridge, you can ensure that it functions optimally and provides reliable filtration for your industrial processes. Remember to inspect the housing, align the cartridge correctly, and monitor pressure drop to ensure that your high flow cartridge continues to perform at its best. With proper installation and maintenance, high flow cartridges can provide years of reliable filtration for your industrial applications.

Case Studies: Successful Implementation of High Flow Cartridges in Industrial Settings

High flow cartridges are an essential component in many industrial applications, providing efficient filtration and ensuring the smooth operation of equipment. In this article, we will explore the successful implementation of high flow cartridges in various industrial settings, highlighting their benefits and advantages.

One of the key advantages of high flow cartridges is their ability to handle large volumes of fluid while maintaining high levels of filtration efficiency. This makes them ideal for applications where a high flow rate is required, such as in the oil and gas industry, chemical processing plants, and water treatment facilities. By using high flow cartridges, companies can ensure that their equipment operates at peak performance while minimizing downtime and maintenance costs.

In a recent case study, a chemical processing plant implemented high flow cartridges in their filtration system to improve the quality of their final product. By using high flow cartridges with a micron rating suitable for their specific application, the plant was able to remove contaminants and impurities from their process water, resulting in a higher quality end product. This not only improved the overall efficiency of the plant but also reduced waste and increased profitability.

Another successful implementation of high flow cartridges was seen in a water treatment facility that was struggling with clogged filters and reduced flow rates. By switching to high flow cartridges, the facility was able to increase the flow rate of their filtration system while maintaining the same level of filtration efficiency. This not only improved the overall performance of the facility but also reduced maintenance costs and downtime, resulting in significant cost savings for the company.

In the oil and gas industry, high flow cartridges are used to filter large volumes of crude oil and natural gas before they are processed further. By using high flow cartridges with a high dirt-holding capacity, companies can ensure that their equipment operates efficiently and effectively, reducing the risk of equipment failure and costly downtime. This has been particularly beneficial for companies operating in remote locations where access to maintenance and replacement parts may be limited.

Overall, the successful implementation of high flow cartridges in industrial settings has proven to be a cost-effective and efficient solution for companies looking to improve the performance of their equipment and processes. By choosing high flow cartridges that are specifically designed for their application, companies can ensure that their filtration systems operate at peak performance while minimizing maintenance costs and downtime.

In conclusion, high flow cartridges are an essential component in many industrial applications, providing efficient filtration and ensuring the smooth operation of equipment. By implementing high flow cartridges in their filtration systems, companies can improve the quality of their final products, increase flow rates, and reduce maintenance costs. With their high dirt-holding capacity and filtration efficiency, high flow cartridges are a cost-effective solution for companies looking to optimize their industrial processes and equipment.