A Comprehensive Guide to Maintaining High Flow Filter Cartridges

Benefits of High Flow Filter Cartridges

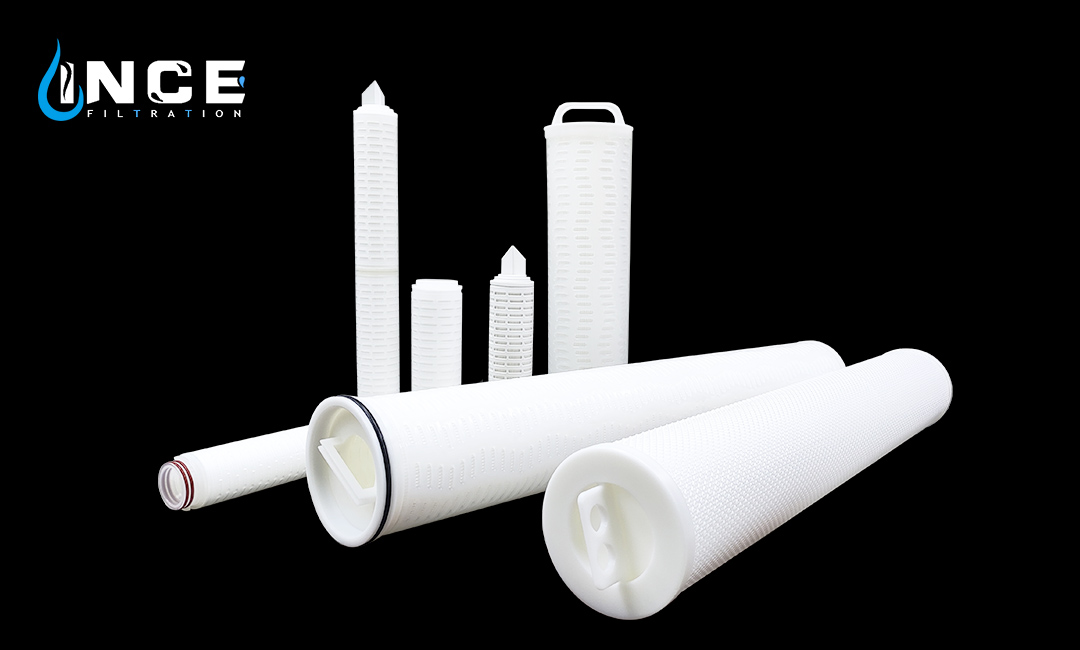

High flow filter cartridges are an essential component in many industrial processes, providing a cost-effective and efficient way to remove contaminants from liquids. These cartridges offer numerous benefits that make them a popular choice for businesses looking to maintain high levels of filtration efficiency.

One of the key benefits of high flow filter cartridges is their ability to handle a large volume of liquid flow. This makes them ideal for applications where a high flow rate is required, such as in the food and beverage industry or in water treatment plants. By using high flow filter cartridges, businesses can ensure that their filtration systems can keep up with the demands of their operations, without sacrificing on the quality of the filtration process.

In addition to their high flow rate capabilities, high flow filter cartridges also offer superior filtration efficiency. These cartridges are designed to remove a wide range of contaminants from liquids, including particles, bacteria, and other impurities. This ensures that the filtered liquid meets the required quality standards, making high flow filter cartridges a reliable choice for businesses that need to maintain high levels of cleanliness in their processes.

Another benefit of high flow filter cartridges is their long service life. These cartridges are built to withstand high flow rates and frequent use, making them a durable and cost-effective option for businesses looking to minimize maintenance and replacement costs. By investing in high flow filter cartridges, businesses can enjoy peace of mind knowing that their filtration systems will continue to operate efficiently for an extended period of time.

Furthermore, high flow filter cartridges are easy to install and maintain, making them a convenient choice for businesses with limited resources or expertise in filtration technology. These cartridges can be quickly and easily replaced when needed, minimizing downtime and ensuring that the filtration system remains operational at all times. This ease of maintenance makes high flow filter cartridges a practical choice for businesses looking to streamline their filtration processes and reduce overall operating costs.

In conclusion, high flow filter cartridges offer a range of benefits that make them a valuable investment for businesses looking to maintain high levels of filtration efficiency. From their ability to handle high flow rates to their superior filtration efficiency and long service life, high flow filter cartridges provide businesses with a reliable and cost-effective solution for their filtration needs. By choosing high flow filter cartridges, businesses can ensure that their processes remain clean, efficient, and compliant with industry standards.

Proper Installation and Replacement Procedures

High flow filter cartridges are essential components in many industrial and commercial applications, providing efficient filtration of liquids and gases to ensure the quality and purity of the final product. Proper installation and replacement procedures are crucial to maintaining the effectiveness and longevity of these filter cartridges. In this comprehensive guide, we will discuss the steps and best practices for installing and replacing high flow filter cartridges to ensure optimal performance and efficiency.

Before installing a new high flow filter cartridge, it is important to carefully inspect the cartridge and the housing to ensure that they are clean and free of any damage. Any debris or contaminants present in the housing can compromise the filtration process and reduce the effectiveness of the filter cartridge. Additionally, inspecting the O-rings and seals for any signs of wear or damage is essential to prevent leaks and ensure a proper seal.

When installing a new high flow filter cartridge, it is important to follow the manufacturer’s instructions carefully. Start by lubricating the O-rings and seals with a compatible lubricant to ensure a proper seal and prevent leaks. Carefully insert the cartridge into the housing, making sure that it is properly aligned and seated securely. Tighten the housing cap or clamp according to the manufacturer’s specifications to ensure a tight seal and prevent bypass of unfiltered fluid.

After installing the new high flow filter cartridge, it is important to perform a system flush to remove any air pockets and ensure proper flow through the filter. Open the inlet and outlet valves slowly to allow the system to fill with fluid and purge any air trapped in the lines. Monitor the system pressure and flow rate to ensure that the filter cartridge is operating within the specified parameters.

Regular maintenance and monitoring of the high flow filter cartridge are essential to ensure optimal performance and efficiency. Check the pressure drop across the filter cartridge regularly to monitor the level of contamination and determine when it is time to replace the cartridge. A significant increase in pressure drop indicates that the filter cartridge is becoming clogged and needs to be replaced.

When replacing a high flow filter cartridge, it is important to follow the same installation procedures as outlined above. Carefully remove the old cartridge, clean the housing, and inspect the O-rings and seals for any signs of wear or damage. Install the new cartridge following the manufacturer’s instructions, lubricating the O-rings and seals and ensuring a proper seal.

In conclusion, proper installation and replacement procedures are essential to maintaining the effectiveness and longevity of high flow filter cartridges. By following the steps and best practices outlined in this guide, you can ensure that your filter cartridges operate at peak performance and provide efficient filtration of liquids and gases in your industrial or commercial application. Regular maintenance and monitoring of the filter cartridges will help to extend their service life and ensure the quality and purity of your final product.

Cleaning and Maintenance Tips

High flow filter cartridges are essential components in many industrial and commercial applications, providing efficient filtration of liquids and gases to ensure the quality and purity of the final product. To maintain the optimal performance of these filter cartridges, regular cleaning and maintenance are crucial. In this comprehensive guide, we will discuss some tips and best practices for maintaining high flow filter cartridges to extend their lifespan and maximize their efficiency.

One of the most important aspects of maintaining high flow filter cartridges is regular cleaning. Over time, dirt, debris, and contaminants can accumulate on the surface of the filter media, reducing its effectiveness and potentially causing damage to the cartridge. To prevent this buildup, it is recommended to clean the filter cartridges at regular intervals, depending on the specific application and operating conditions.

Before cleaning the filter cartridges, it is important to shut off the flow of liquid or gas and depressurize the system to ensure safety. Once the cartridges are safely removed from the system, they can be cleaned using a variety of methods, including backwashing, chemical cleaning, or mechanical cleaning. Backwashing involves reversing the flow of liquid or gas through the filter cartridge to dislodge and remove trapped particles. Chemical cleaning involves using specialized cleaning agents to dissolve and remove contaminants from the filter media. Mechanical cleaning involves physically scrubbing the filter media to remove stubborn deposits.

After cleaning the filter cartridges, it is important to inspect them for any signs of damage or wear. Check for tears, holes, or other defects in the filter media, as these can compromise the filtration efficiency of the cartridge. If any damage is found, it is recommended to replace the filter cartridge with a new one to ensure optimal performance.

In addition to regular cleaning, proper storage of high flow filter cartridges is also important to maintain their effectiveness. Store the cartridges in a clean, dry, and well-ventilated area to prevent the growth of mold, mildew, or bacteria. Avoid exposing the cartridges to extreme temperatures or direct sunlight, as this can degrade the filter media and reduce its lifespan.

Another important aspect of maintaining high flow filter cartridges is monitoring their performance over time. Keep track of the pressure drop across the filter cartridges, as an increase in pressure drop can indicate a clogged or dirty filter. Regularly check the flow rate of the system to ensure that the filter cartridges are not restricting the flow of liquid or gas. If any abnormalities are detected, take corrective action immediately to prevent damage to the filter cartridges and ensure the continued efficiency of the filtration system.

In conclusion, maintaining high flow filter cartridges is essential to ensure the optimal performance and longevity of these critical components. By following the tips and best practices outlined in this guide, you can extend the lifespan of your filter cartridges and maximize their efficiency in filtering liquids and gases. Regular cleaning, proper storage, and monitoring of performance are key aspects of maintaining high flow filter cartridges, so be sure to incorporate these practices into your maintenance routine to keep your filtration system running smoothly.

Troubleshooting Common Issues

High flow filter cartridges are an essential component in many industrial processes, helping to remove contaminants and impurities from liquids and gases. However, like any piece of equipment, they require regular maintenance to ensure optimal performance. In this comprehensive guide, we will discuss common issues that can arise with high flow filter cartridges and provide troubleshooting tips to help you keep your system running smoothly.

One of the most common issues that can occur with high flow filter cartridges is clogging. Over time, contaminants can build up on the surface of the filter, reducing its effectiveness and causing a drop in flow rate. If you notice a decrease in flow rate or pressure, it may be a sign that your filter cartridge is clogged. To troubleshoot this issue, you can try backwashing the filter or replacing the cartridge altogether.

Another common issue with high flow filter cartridges is leaks. Leaks can occur for a variety of reasons, including damaged seals or gaskets, improper installation, or excessive pressure. If you notice a leak in your system, it is important to address it promptly to prevent further damage. Check the seals and gaskets for any signs of wear or damage, and replace them if necessary. Additionally, make sure that the filter cartridge is installed correctly and that the system is operating within the recommended pressure range.

In some cases, high flow filter cartridges may become damaged or worn out over time. This can result in poor filtration performance and reduced efficiency. If you notice any signs of damage, such as tears or holes in the filter material, it is important to replace the cartridge as soon as possible. Regularly inspecting your filter cartridges for signs of wear and tear can help prevent costly repairs and downtime.

One of the best ways to prevent common issues with high flow filter cartridges is to establish a regular maintenance schedule. By regularly inspecting and cleaning your filter cartridges, you can help prolong their lifespan and ensure optimal performance. Make sure to follow the manufacturer’s recommendations for maintenance and replacement intervals, and keep detailed records of your maintenance activities.

In conclusion, maintaining high flow filter cartridges is essential for ensuring the efficiency and effectiveness of your filtration system. By addressing common issues such as clogging, leaks, and damage promptly, you can prevent costly repairs and downtime. Establishing a regular maintenance schedule and following the manufacturer’s recommendations can help prolong the lifespan of your filter cartridges and keep your system running smoothly. Remember, proper maintenance is key to maximizing the performance of your high flow filter cartridges and ensuring the quality of your end products.