Applications of High Flow Filter Elements in Oil and Gas Industry

Benefits of Using High Flow Filter Elements in Oil and Gas Industry

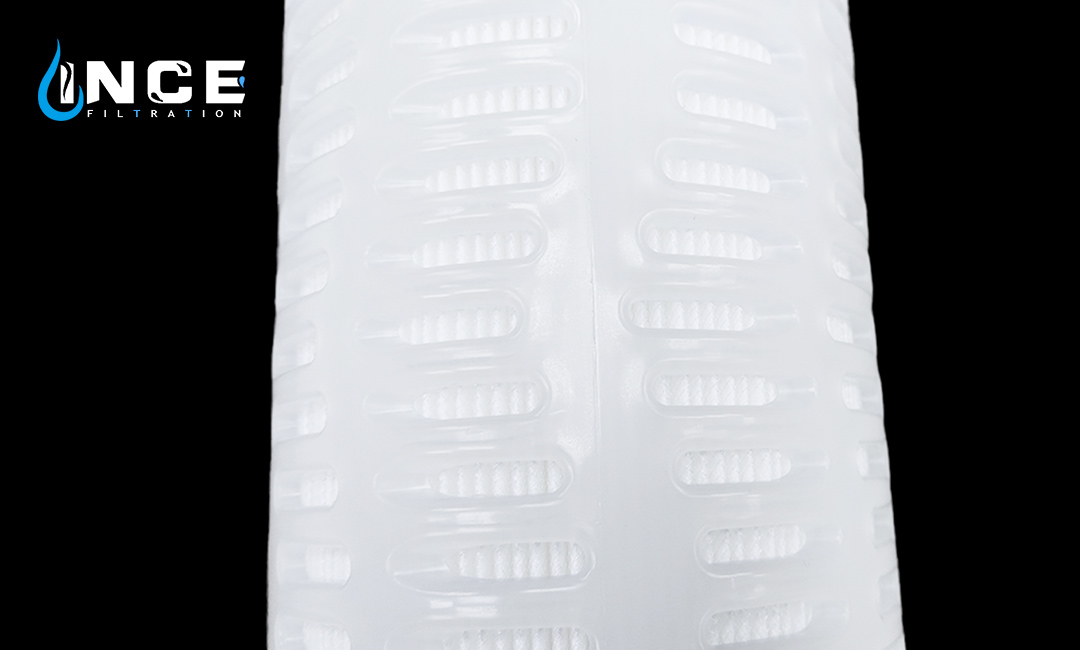

High flow filter elements play a crucial role in the oil and gas industry by ensuring the quality and purity of fluids used in various processes. These filter elements are designed to handle high flow rates while effectively removing contaminants such as dirt, debris, and other particles that can compromise the integrity of equipment and machinery. In this article, we will explore the benefits of using high flow filter elements in the oil and gas industry.

One of the primary benefits of high flow filter elements is their ability to improve operational efficiency. By effectively removing contaminants from fluids, these filter elements help prevent equipment breakdowns and reduce maintenance costs. This, in turn, leads to increased uptime and productivity, allowing companies in the oil and gas industry to maximize their output and profitability.

Furthermore, high flow filter elements help ensure the safety of workers and the environment by maintaining the quality of fluids used in various processes. Contaminated fluids can pose serious health risks to workers and can also have a negative impact on the environment if not properly managed. By using high flow filter elements, companies can mitigate these risks and demonstrate their commitment to safety and environmental stewardship.

Another key benefit of high flow filter elements is their versatility and adaptability to different applications in the oil and gas industry. These filter elements can be customized to meet specific requirements, such as flow rates, pressure levels, and filtration efficiency. This flexibility allows companies to tailor their filtration systems to suit their unique needs and challenges, ensuring optimal performance and reliability.

In addition, high flow filter elements are cost-effective solutions for companies in the oil and gas industry. By investing in high-quality filter elements, companies can reduce the frequency of filter replacements and maintenance, leading to long-term cost savings. Furthermore, the improved operational efficiency and reduced downtime resulting from the use of high flow filter elements can translate into significant financial benefits for companies in the long run.

Moreover, high flow filter elements help companies in the oil and gas industry comply with regulatory requirements and industry standards. By maintaining the quality of fluids used in various processes, companies can ensure that they meet the necessary guidelines and avoid potential fines or penalties. This not only helps protect the company’s reputation but also demonstrates its commitment to upholding the highest standards of quality and safety.

In conclusion, high flow filter elements offer a wide range of benefits for companies in the oil and gas industry. From improving operational efficiency and ensuring worker safety to reducing maintenance costs and complying with regulatory requirements, these filter elements play a critical role in enhancing the overall performance and reliability of filtration systems. By investing in high-quality filter elements, companies can achieve significant cost savings, increase productivity, and demonstrate their commitment to excellence in the oil and gas industry.

Importance of Proper Filtration in Oil and Gas Applications

The oil and gas industry is a critical sector that plays a vital role in powering the global economy. With the increasing demand for energy, the industry is constantly striving to improve efficiency and productivity. One crucial aspect of oil and gas operations is the filtration of fluids to ensure the smooth functioning of equipment and machinery. Proper filtration is essential to prevent contamination, reduce downtime, and extend the lifespan of equipment.

High flow filter elements are an integral part of the filtration process in the oil and gas industry. These filter elements are designed to handle high flow rates while effectively removing contaminants from fluids. They are commonly used in various applications such as hydraulic systems, lubrication systems, and fuel systems. High flow filter elements are capable of capturing particles as small as a few microns, ensuring that the fluids are clean and free from impurities.

In the oil and gas industry, the use of high flow filter elements is crucial for maintaining the integrity of equipment and machinery. Contaminants such as dirt, debris, and water can cause damage to critical components, leading to costly repairs and downtime. By using high flow filter elements, operators can effectively remove these contaminants and protect their equipment from premature wear and failure.

One of the key benefits of high flow filter elements is their ability to handle large volumes of fluid without compromising filtration efficiency. This is particularly important in high-flow applications where a significant amount of fluid needs to be filtered quickly. High flow filter elements are designed to withstand high pressure and flow rates, making them ideal for use in demanding oil and gas environments.

Another advantage of high flow filter elements is their long service life and durability. These filter elements are constructed from high-quality materials that are resistant to corrosion and degradation. This ensures that they can withstand harsh operating conditions and continue to perform effectively over an extended period of time. By using high flow filter elements, operators can reduce maintenance costs and minimize downtime associated with filter replacement.

In addition to their filtration capabilities, high flow filter elements also play a crucial role in ensuring the safety and reliability of oil and gas operations. Clean fluids are essential for the proper functioning of equipment and machinery, as well as for the protection of personnel and the environment. By using high flow filter elements, operators can maintain the cleanliness of fluids and prevent contamination that could lead to accidents or environmental damage.

Overall, the applications of high flow filter elements in the oil and gas industry are vast and varied. From hydraulic systems to fuel systems, these filter elements are essential for maintaining the efficiency and reliability of equipment. By investing in high-quality filter elements and implementing proper filtration practices, operators can ensure the smooth operation of their oil and gas facilities while minimizing the risk of equipment failure and downtime.

Case Studies on Successful Implementation of High Flow Filter Elements

High flow filter elements play a crucial role in the oil and gas industry, where the need for efficient filtration of fluids is paramount. These filter elements are designed to handle high flow rates while maintaining the required level of filtration efficiency. In this article, we will explore some case studies that demonstrate the successful implementation of high flow filter elements in the oil and gas industry.

One of the key applications of high flow filter elements in the oil and gas industry is in the filtration of produced water. Produced water is a byproduct of oil and gas production that contains various contaminants, including oil, solids, and chemicals. Efficient filtration of produced water is essential to meet environmental regulations and ensure the proper disposal or reuse of the water.

In a case study conducted by a major oil and gas company, high flow filter elements were used to treat produced water from an offshore platform. The filter elements were able to handle the high flow rates of produced water while effectively removing oil and solids from the water. This resulted in a significant reduction in the amount of oil and solids discharged into the environment, leading to improved environmental compliance and reduced environmental impact.

Another application of high flow filter elements in the oil and gas industry is in the filtration of hydraulic fluids. Hydraulic systems are widely used in the oil and gas industry for various applications, including drilling, well stimulation, and pipeline operations. Contaminants in hydraulic fluids can cause damage to equipment and lead to costly downtime.

In a case study conducted by a drilling company, high flow filter elements were installed in the hydraulic systems of their drilling rigs. The filter elements were able to effectively remove contaminants from the hydraulic fluids, ensuring the smooth operation of the equipment and reducing the risk of equipment failure. This resulted in improved equipment reliability, reduced maintenance costs, and increased operational efficiency.

High flow filter elements are also used in the filtration of fuel and lubricants in the oil and gas industry. Contaminants in fuel and lubricants can cause engine damage, reduce equipment performance, and increase maintenance costs. Efficient filtration of fuel and lubricants is essential to ensure the proper operation of equipment and prevent costly downtime.

In a case study conducted by a transportation company, high flow filter elements were installed in the fuel and lubricant systems of their fleet of vehicles. The filter elements were able to effectively remove contaminants from the fuel and lubricants, leading to improved engine performance, reduced maintenance costs, and increased fuel efficiency. This resulted in significant cost savings for the company and improved the overall reliability of their fleet.

In conclusion, high flow filter elements play a critical role in the oil and gas industry, where efficient filtration of fluids is essential to ensure environmental compliance, equipment reliability, and operational efficiency. The case studies discussed in this article demonstrate the successful implementation of high flow filter elements in various applications in the oil and gas industry, highlighting the benefits of using these filter elements to improve performance and reduce costs.

Future Trends in High Flow Filtration Technology for Oil and Gas Industry

High flow filter elements play a crucial role in the oil and gas industry by ensuring the purity of fluids used in various processes. These filter elements are designed to handle high flow rates while effectively removing contaminants from the fluid. In recent years, there has been a growing demand for high flow filtration technology in the oil and gas industry due to its efficiency and reliability.

One of the key applications of high flow filter elements in the oil and gas industry is in the filtration of hydraulic fluids. Hydraulic systems are widely used in the industry for various operations, such as drilling, pumping, and transportation. These systems require clean and contaminant-free hydraulic fluids to operate efficiently and prevent equipment failure. High flow filter elements are capable of removing particles, water, and other contaminants from hydraulic fluids, ensuring smooth and reliable operation of hydraulic systems.

Another important application of high flow filter elements in the oil and gas industry is in the filtration of lubricating oils. Lubricating oils are used to reduce friction and wear in machinery and equipment, prolonging their lifespan and improving efficiency. However, these oils can become contaminated with particles, water, and other impurities over time, leading to equipment failure and downtime. High flow filter elements are designed to effectively remove contaminants from lubricating oils, ensuring optimal performance and longevity of equipment.

High flow filter elements are also used in the filtration of fuel oils in the oil and gas industry. Fuel oils are essential for powering various equipment and vehicles in the industry, such as generators, pumps, and vehicles. Contaminated fuel oils can lead to engine damage, reduced efficiency, and increased maintenance costs. High flow filter elements are capable of removing particles, water, and other impurities from fuel oils, ensuring clean and reliable fuel supply for equipment and vehicles.

In addition to these applications, high flow filter elements are also used in the filtration of process fluids in the oil and gas industry. Process fluids, such as water, chemicals, and solvents, are used in various operations, such as refining, extraction, and transportation. These fluids need to be free of contaminants to prevent equipment corrosion, product contamination, and environmental damage. High flow filter elements are designed to handle large volumes of process fluids while effectively removing contaminants, ensuring the quality and integrity of the final product.

As the oil and gas industry continues to evolve and expand, the demand for high flow filtration technology is expected to grow. Advancements in filter element design, materials, and manufacturing processes are driving the development of more efficient and reliable high flow filter elements for the industry. Future trends in high flow filtration technology for the oil and gas industry include the use of advanced materials, such as nanofibers and membranes, to improve filtration efficiency and performance.

Overall, high flow filter elements play a critical role in ensuring the purity and quality of fluids used in the oil and gas industry. From hydraulic fluids to lubricating oils, fuel oils, and process fluids, high flow filter elements are essential for maintaining equipment reliability, efficiency, and safety. With ongoing advancements in technology and materials, high flow filtration technology is poised to play an even greater role in the future of the oil and gas industry.