Applications of High Flow Pleated Filters in Industrial Processes

Benefits of Using High Flow Pleated Filters in Industrial Processes

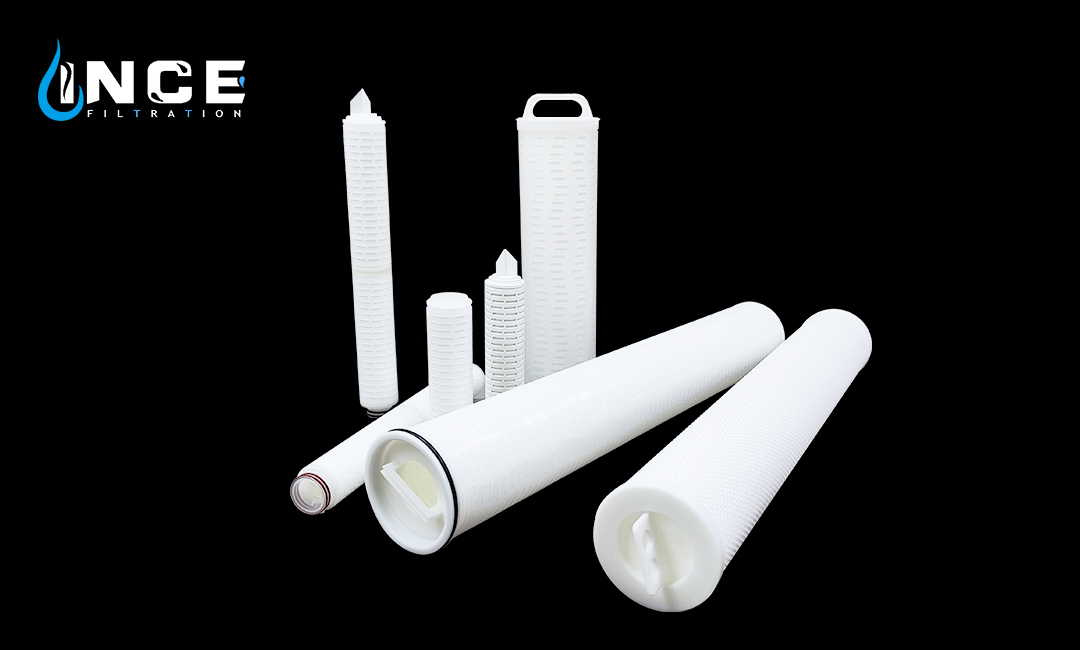

High flow pleated filters are an essential component in many industrial processes, providing a cost-effective and efficient solution for removing contaminants from liquids and gases. These filters offer numerous benefits that make them a popular choice for a wide range of applications.

One of the key advantages of high flow pleated filters is their ability to handle high flow rates while maintaining a low pressure drop. This means that they can effectively filter large volumes of fluid without causing a significant decrease in system performance. This is particularly important in industrial processes where maintaining a consistent flow rate is critical to the overall operation of the system.

In addition to their high flow capacity, pleated filters also offer a large filtration area, which allows them to capture a greater amount of contaminants before needing to be replaced. This not only reduces the frequency of filter changes but also helps to prolong the life of downstream equipment by preventing the buildup of harmful particles.

Another benefit of high flow pleated filters is their versatility. These filters can be used in a wide range of applications, from water treatment and chemical processing to food and beverage production. Their ability to effectively remove contaminants of various sizes makes them a valuable tool in maintaining the quality and purity of liquids and gases in industrial processes.

Furthermore, high flow pleated filters are easy to install and replace, making them a convenient option for busy industrial facilities. Their compact design and lightweight construction make them easy to handle, while their durable materials ensure long-lasting performance even in harsh operating conditions.

In addition to their practical benefits, high flow pleated filters also offer cost savings for industrial operations. By reducing the need for frequent filter changes and minimizing downtime due to clogged filters, these filters help to lower maintenance costs and improve overall efficiency. This can result in significant savings over time, making high flow pleated filters a smart investment for businesses looking to optimize their processes.

Overall, the applications of high flow pleated filters in industrial processes are vast and varied. From improving system performance and prolonging equipment life to reducing maintenance costs and ensuring product quality, these filters offer a range of benefits that make them an essential component in many industries. Whether used in water treatment, chemical processing, or food and beverage production, high flow pleated filters provide a reliable and cost-effective solution for removing contaminants and maintaining the integrity of liquids and gases in industrial processes.

Case Studies on the Efficiency of High Flow Pleated Filters in Industrial Applications

High flow pleated filters have become an essential component in various industrial processes due to their efficiency and effectiveness in removing contaminants from liquids. These filters are designed to handle high flow rates while maintaining a high level of filtration efficiency, making them ideal for applications where large volumes of liquid need to be filtered quickly and effectively.

One common application of high flow pleated filters is in the water treatment industry. Water treatment plants rely on these filters to remove impurities and contaminants from water sources before it can be used for drinking, irrigation, or industrial purposes. The high flow rate of these filters allows for a large volume of water to be processed in a short amount of time, ensuring that clean and safe water is available for consumption.

In the oil and gas industry, high flow pleated filters are used to remove particulates and contaminants from crude oil and natural gas before they can be processed further. These filters are capable of handling the high flow rates associated with oil and gas production, making them an essential component in ensuring the quality and purity of these valuable resources.

Another application of high flow pleated filters is in the pharmaceutical industry, where they are used to remove bacteria, viruses, and other contaminants from pharmaceutical products during the manufacturing process. The high filtration efficiency of these filters ensures that the final product meets the strict quality standards required for pharmaceutical products.

In the food and beverage industry, high flow pleated filters are used to remove impurities and contaminants from liquids such as juices, soft drinks, and beer. These filters help to ensure that the final product is free from any harmful substances and meets the quality standards set by regulatory bodies.

One of the key advantages of high flow pleated filters is their long service life and low maintenance requirements. These filters are designed to withstand high flow rates and can operate continuously for extended periods without the need for frequent replacement or cleaning. This makes them a cost-effective solution for industrial processes that require reliable and efficient filtration.

In a recent case study conducted in a manufacturing plant, high flow pleated filters were installed in the water treatment system to improve the quality of the water used in the production process. The filters were able to remove a high percentage of contaminants from the water, resulting in a significant improvement in the quality of the final product. The plant saw a reduction in downtime and maintenance costs, as well as an increase in production efficiency.

In another case study conducted in an oil refinery, high flow pleated filters were used to remove particulates and contaminants from the crude oil before it was processed further. The filters were able to handle the high flow rates associated with oil production and effectively remove impurities from the crude oil, resulting in a higher quality end product. The refinery saw an improvement in the efficiency of their production process and a reduction in maintenance costs.

Overall, high flow pleated filters have proven to be a valuable asset in various industrial processes, providing efficient and reliable filtration solutions for a wide range of applications. Their high filtration efficiency, long service life, and low maintenance requirements make them an ideal choice for industries that require effective contaminant removal from liquids. Whether it is in water treatment, oil and gas production, pharmaceutical manufacturing, or food and beverage processing, high flow pleated filters continue to play a crucial role in ensuring the quality and purity of industrial products.

Future Trends and Innovations in High Flow Pleated Filters for Industrial Processes

High flow pleated filters are an essential component in many industrial processes, providing efficient filtration of liquids and gases to ensure the quality and safety of the final product. These filters are designed to handle high flow rates while maintaining a high level of filtration efficiency, making them ideal for a wide range of applications in industries such as pharmaceuticals, food and beverage, chemicals, and water treatment.

One of the key advantages of high flow pleated filters is their ability to handle large volumes of fluid without sacrificing filtration performance. This makes them particularly well-suited for applications where high flow rates are required, such as in the production of pharmaceuticals or the treatment of wastewater. By using high flow pleated filters, companies can increase their production efficiency and reduce downtime, ultimately leading to cost savings and improved overall productivity.

In the pharmaceutical industry, high flow pleated filters are used to ensure the purity of drugs and medical devices by removing contaminants and impurities from the manufacturing process. These filters are designed to meet the stringent requirements of the industry, providing a high level of filtration efficiency and reliability. By using high flow pleated filters, pharmaceutical companies can maintain the quality and safety of their products, ensuring compliance with regulatory standards and protecting the health of consumers.

In the food and beverage industry, high flow pleated filters are used to remove particles, bacteria, and other contaminants from liquids such as water, juices, and dairy products. These filters help to improve the quality and shelf life of food and beverage products, ensuring that they meet the highest standards of safety and hygiene. By using high flow pleated filters, companies can enhance the taste, appearance, and overall quality of their products, leading to increased customer satisfaction and loyalty.

In the chemical industry, high flow pleated filters are used to remove impurities and contaminants from chemicals and solvents, ensuring the purity and consistency of the final product. These filters are designed to withstand the harsh conditions of chemical processing, providing reliable filtration performance and long-lasting durability. By using high flow pleated filters, chemical companies can improve the efficiency and reliability of their production processes, reducing the risk of contamination and ensuring the quality of their products.

In the water treatment industry, high flow pleated filters are used to remove suspended solids, bacteria, and other contaminants from water sources, ensuring the safety and purity of drinking water and industrial process water. These filters are designed to handle large volumes of water while maintaining a high level of filtration efficiency, making them ideal for applications such as municipal water treatment plants, industrial wastewater treatment facilities, and desalination plants. By using high flow pleated filters, water treatment companies can improve the quality of their water sources, protect the environment, and ensure the health and safety of the communities they serve.

Overall, high flow pleated filters play a crucial role in a wide range of industrial processes, providing efficient filtration of liquids and gases to ensure the quality and safety of the final product. With their high flow rates, filtration efficiency, and reliability, these filters are essential components in industries such as pharmaceuticals, food and beverage, chemicals, and water treatment. As technology continues to advance, we can expect to see further innovations in high flow pleated filters, leading to even greater efficiency, performance, and cost savings for companies across various industries.