Applications of Polyester Spiral Drying Fabric in Filtration Systems

Benefits of Using Polyester Spiral Drying Fabric in Filtration Systems

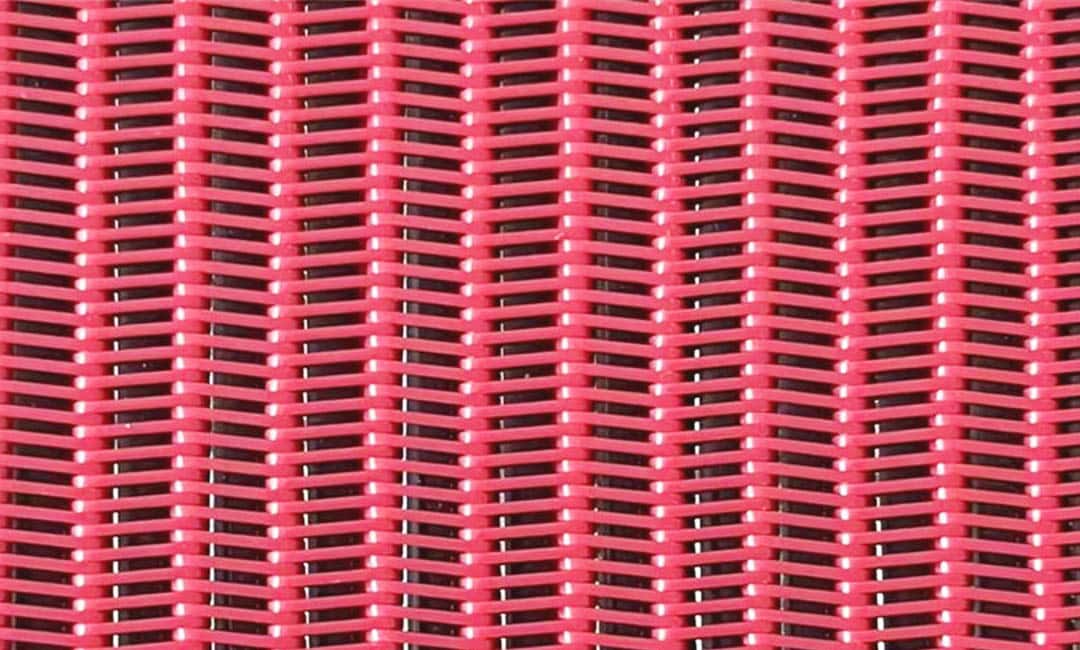

Polyester spiral drying fabric is a versatile material that has found numerous applications in various industries, including filtration systems. This fabric is made from high-quality polyester monofilament yarns, which are woven together in a spiral pattern to create a strong and durable mesh. The unique design of polyester spiral drying fabric allows for excellent air and liquid permeability, making it an ideal choice for filtration systems.

One of the key benefits of using polyester spiral drying fabric in filtration systems is its ability to effectively remove solid particles from liquids. The open mesh structure of the fabric allows for efficient filtration, trapping particles of various sizes while allowing the liquid to pass through. This makes polyester spiral drying fabric an excellent choice for applications where fine filtration is required, such as in wastewater treatment plants or food processing facilities.

In addition to its superior filtration capabilities, polyester spiral drying fabric is also highly resistant to chemicals and abrasion. This makes it a durable and long-lasting option for filtration systems that are exposed to harsh operating conditions. The fabric can withstand high temperatures and aggressive chemicals without losing its structural integrity, ensuring reliable performance over an extended period of time.

Another advantage of using polyester spiral drying fabric in filtration systems is its ease of maintenance. The smooth surface of the fabric prevents particles from becoming trapped, making it easy to clean and maintain. This reduces downtime and maintenance costs, making polyester spiral drying fabric a cost-effective choice for filtration applications.

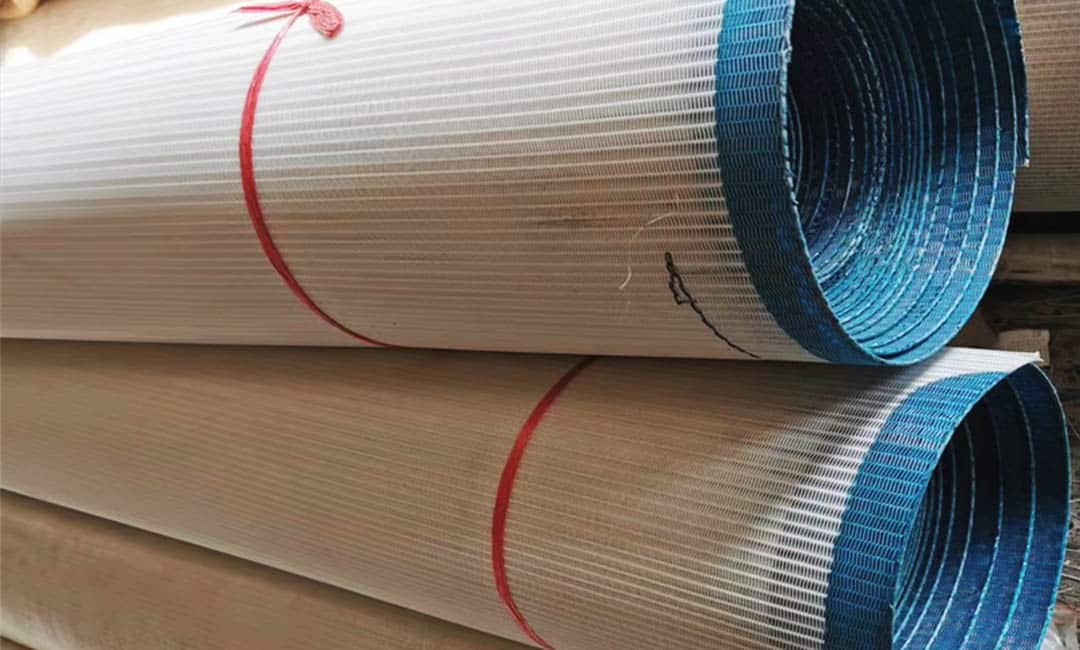

Furthermore, polyester spiral drying fabric is lightweight and flexible, making it easy to install and replace in filtration systems. The fabric can be easily cut to size and shaped to fit different filtration equipment, allowing for customization to meet specific requirements. This flexibility makes polyester spiral drying fabric a versatile option for a wide range of filtration applications.

Overall, the benefits of using polyester spiral drying fabric in filtration systems are clear. Its superior filtration capabilities, chemical resistance, ease of maintenance, and flexibility make it an excellent choice for applications where reliable and efficient filtration is essential. Whether used in wastewater treatment plants, food processing facilities, or industrial filtration systems, polyester spiral drying fabric offers a cost-effective and reliable solution for achieving high-quality filtration results.

In conclusion, polyester spiral drying fabric is a valuable material that has revolutionized the field of filtration systems. Its unique design and superior properties make it an ideal choice for applications where efficient filtration is crucial. By utilizing polyester spiral drying fabric in filtration systems, industries can benefit from improved performance, reduced maintenance costs, and increased durability. With its many advantages, polyester spiral drying fabric is sure to continue playing a key role in the advancement of filtration technology in the years to come.

How Polyester Spiral Drying Fabric Improves Filtration Efficiency

Polyester spiral drying fabric is a versatile material that has found numerous applications in various industries, including filtration systems. This fabric is made from high-quality polyester monofilament yarns that are woven together in a spiral pattern, creating a strong and durable mesh structure. The unique design of polyester spiral drying fabric allows for excellent air and liquid permeability, making it an ideal choice for filtration applications.

One of the key benefits of using polyester spiral drying fabric in filtration systems is its ability to improve filtration efficiency. The open mesh structure of the fabric allows for easy passage of air and liquids, while trapping solid particles and contaminants. This results in cleaner filtrate and higher filtration rates, making the filtration process more efficient and cost-effective.

In addition to improving filtration efficiency, polyester spiral drying fabric also offers excellent cake release properties. The smooth surface of the fabric prevents solid particles from sticking to the mesh, making it easier to remove the filter cake after filtration. This not only saves time and labor but also ensures a more thorough cleaning of the filter, prolonging its lifespan and reducing maintenance costs.

Furthermore, polyester spiral drying fabric is highly resistant to chemicals, abrasion, and high temperatures, making it suitable for a wide range of filtration applications. Whether filtering water, chemicals, or food products, this fabric can withstand harsh operating conditions without compromising its performance. This durability and reliability make polyester spiral drying fabric a popular choice for industries that require consistent and efficient filtration processes.

Another advantage of using polyester spiral drying fabric in filtration systems is its versatility. This fabric can be customized to meet specific filtration requirements, such as pore size, mesh count, and thickness. This flexibility allows for greater control over the filtration process, ensuring optimal performance and quality of the filtrate.

Moreover, polyester spiral drying fabric is easy to clean and maintain, thanks to its non-stick properties and resistance to clogging. Regular cleaning and maintenance of the fabric can help prolong its lifespan and ensure consistent filtration performance over time. This makes polyester spiral drying fabric a cost-effective and reliable solution for industries that rely on efficient filtration systems.

In conclusion, polyester spiral drying fabric offers numerous benefits for filtration systems, including improved filtration efficiency, excellent cake release properties, chemical resistance, and versatility. Its durability, reliability, and ease of maintenance make it a popular choice for industries that require high-performance filtration solutions. By incorporating polyester spiral drying fabric into their filtration systems, businesses can achieve cleaner filtrate, higher filtration rates, and cost savings in the long run.

Case Studies of Successful Applications of Polyester Spiral Drying Fabric in Filtration Systems

Polyester spiral drying fabric is a versatile material that has found numerous applications in filtration systems across various industries. Its unique properties make it an ideal choice for filtering and drying processes, providing efficient and effective solutions for a wide range of applications.

One of the key advantages of polyester spiral drying fabric is its high tensile strength and durability. This makes it suitable for use in demanding filtration systems where the fabric is subjected to high pressures and temperatures. Its ability to withstand harsh conditions without losing its shape or integrity makes it a reliable choice for continuous operation in industrial settings.

In addition to its strength, polyester spiral drying fabric is also known for its excellent filtration properties. The tight weave of the fabric allows for efficient separation of solids and liquids, making it an effective tool for removing impurities from various substances. This makes it an essential component in filtration systems used in industries such as food and beverage, pharmaceuticals, and wastewater treatment.

One successful application of polyester spiral drying fabric is in the production of paper and pulp. The fabric is used in the drying section of paper machines to remove water from the paper pulp, resulting in a dry and smooth finished product. Its high permeability and uniform airflow ensure even drying of the paper, leading to improved quality and productivity in the paper manufacturing process.

Another common application of polyester spiral drying fabric is in the wastewater treatment industry. The fabric is used in belt filter presses to dewater sludge and separate solids from liquids in the treatment process. Its high filtration efficiency and resistance to chemical corrosion make it an ideal choice for handling the abrasive and corrosive nature of wastewater sludge.

Polyester spiral drying fabric is also widely used in the food and beverage industry for filtering and drying applications. It is commonly used in the production of sugar, salt, and other food products to remove impurities and excess moisture, resulting in a high-quality end product. Its food-grade certification and easy cleanability make it a safe and hygienic choice for food processing applications.

Overall, the applications of polyester spiral drying fabric in filtration systems are diverse and widespread. Its strength, durability, and filtration properties make it a valuable tool for a variety of industries seeking efficient and reliable filtration solutions. Whether used in paper manufacturing, wastewater treatment, or food processing, polyester spiral drying fabric continues to prove its effectiveness in improving processes and product quality.

In conclusion, polyester spiral drying fabric is a versatile material that has found successful applications in filtration systems across various industries. Its unique properties make it an ideal choice for filtering and drying processes, providing efficient and effective solutions for a wide range of applications. From paper manufacturing to wastewater treatment to food processing, polyester spiral drying fabric continues to play a crucial role in improving processes and product quality in diverse industries.