Applications of Ultipleat High Flow Filters in Chemical Processing

Improved Efficiency in Chemical Processing with Ultipleat High Flow Filters

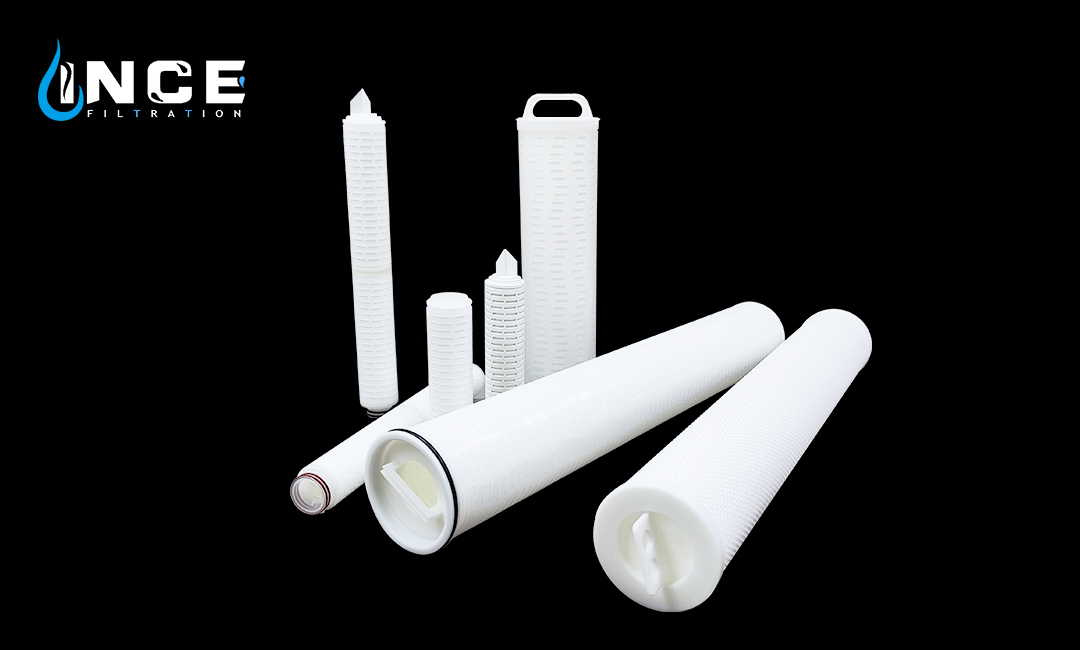

Chemical processing is a complex and intricate industry that requires precision and efficiency in order to produce high-quality products. One key component in this process is filtration, which plays a crucial role in removing impurities and ensuring the purity of the final product. Ultipleat High Flow Filters have emerged as a popular choice in the chemical processing industry due to their superior performance and efficiency.

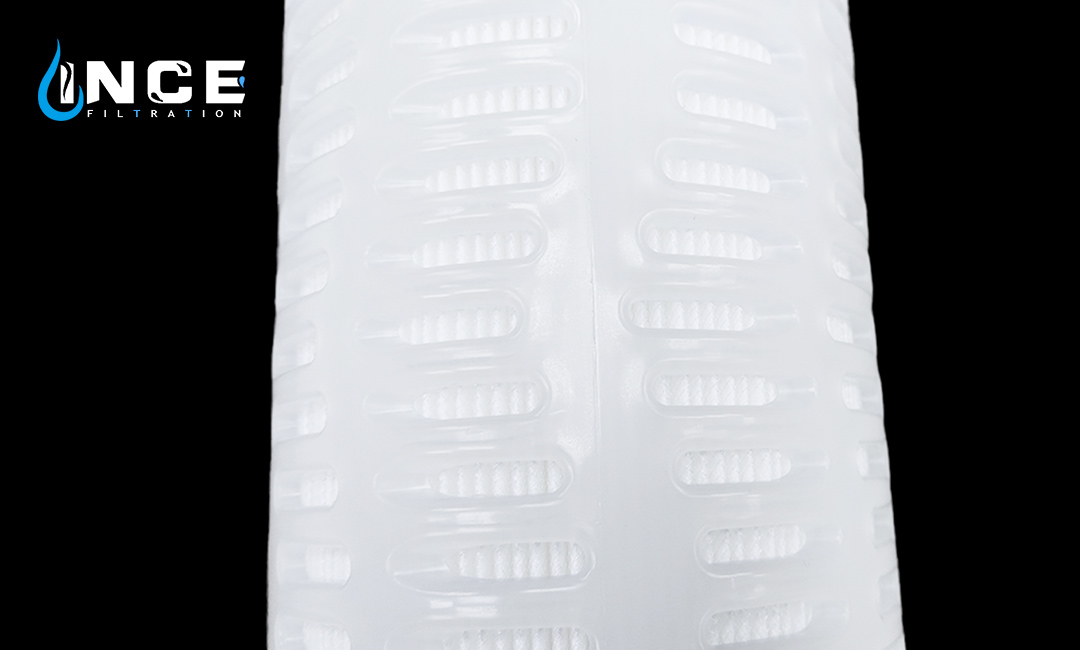

One of the main advantages of Ultipleat High Flow Filters is their high flow rates, which allow for faster filtration and increased productivity. This is especially important in chemical processing, where time is of the essence and any delays can result in costly downtime. By using Ultipleat High Flow Filters, companies can streamline their filtration processes and achieve higher throughput without sacrificing quality.

In addition to their high flow rates, Ultipleat High Flow Filters also offer excellent particle retention and removal efficiency. This is crucial in chemical processing, where even the smallest impurities can have a significant impact on the quality of the final product. Ultipleat High Flow Filters are designed to capture particles of all sizes, ensuring that the end product meets the strictest quality standards.

Another key benefit of Ultipleat High Flow Filters is their long service life and durability. These filters are built to withstand the harsh conditions of chemical processing, including high temperatures, corrosive chemicals, and high pressures. This means that companies can rely on Ultipleat High Flow Filters to deliver consistent performance and reliable filtration over an extended period of time.

Ultipleat High Flow Filters are also highly versatile and can be used in a wide range of applications within the chemical processing industry. Whether it’s removing contaminants from raw materials, purifying solvents and reagents, or clarifying final products, Ultipleat High Flow Filters can handle it all. This versatility makes them a cost-effective solution for companies looking to streamline their filtration processes and improve overall efficiency.

Furthermore, Ultipleat High Flow Filters are easy to install and maintain, reducing the need for costly downtime and maintenance. This is a significant advantage for companies in the chemical processing industry, where any disruptions to production can have serious consequences. With Ultipleat High Flow Filters, companies can minimize downtime and keep their operations running smoothly.

In conclusion, Ultipleat High Flow Filters are a valuable tool for improving efficiency in chemical processing. Their high flow rates, excellent particle retention, durability, versatility, and ease of maintenance make them an ideal choice for companies looking to optimize their filtration processes. By investing in Ultipleat High Flow Filters, companies can achieve higher throughput, better quality control, and increased productivity in their chemical processing operations.

Cost Savings and Environmental Benefits of Using Ultipleat High Flow Filters in Chemical Processing

Ultipleat High Flow Filters have become an essential tool in the chemical processing industry due to their efficiency, cost-effectiveness, and environmental benefits. These filters are designed to handle high flow rates while maintaining a high level of filtration efficiency, making them ideal for a wide range of applications in the chemical processing industry.

One of the key benefits of using Ultipleat High Flow Filters in chemical processing is the cost savings they offer. These filters have a longer service life compared to traditional filters, which means less frequent filter changes and reduced downtime for maintenance. This not only saves on labor costs but also reduces the need for replacement filters, resulting in significant cost savings over time.

In addition to cost savings, Ultipleat High Flow Filters also offer environmental benefits. By reducing the frequency of filter changes, these filters help to minimize waste generation and reduce the environmental impact of chemical processing operations. This is particularly important in industries where large volumes of chemicals are used and disposed of on a regular basis.

Furthermore, Ultipleat High Flow Filters are designed to provide superior filtration performance, ensuring that contaminants are effectively removed from the process stream. This helps to improve product quality and consistency, leading to higher yields and reduced product losses. In addition, the high flow rates of these filters allow for faster processing times, increasing overall efficiency and productivity in chemical processing operations.

Another advantage of using Ultipleat High Flow Filters in chemical processing is their versatility. These filters can be customized to meet the specific requirements of different applications, making them suitable for a wide range of chemical processing operations. Whether filtering corrosive chemicals, high-viscosity fluids, or abrasive materials, Ultipleat High Flow Filters can be tailored to provide optimal filtration performance.

Overall, the applications of Ultipleat High Flow Filters in chemical processing are vast and varied. From removing contaminants and impurities from process streams to improving product quality and consistency, these filters offer a range of benefits that can help chemical processing operations run more efficiently and cost-effectively.

In conclusion, Ultipleat High Flow Filters are a valuable tool for the chemical processing industry, offering cost savings, environmental benefits, and superior filtration performance. By incorporating these filters into their operations, chemical processing companies can improve efficiency, reduce costs, and minimize their environmental footprint. Ultimately, Ultipleat High Flow Filters are a smart investment for any chemical processing operation looking to enhance their filtration capabilities and optimize their processes.

Enhancing Product Quality and Consistency Through Ultipleat High Flow Filters in Chemical Processing

In the realm of chemical processing, maintaining product quality and consistency is paramount. Any deviation in the composition or purity of chemicals can have far-reaching consequences, from compromising the effectiveness of end products to posing safety risks. To address these challenges, many chemical processing plants have turned to Ultipleat High Flow Filters as a reliable solution.

Ultipleat High Flow Filters are designed to handle high flow rates while maintaining excellent filtration efficiency. This makes them ideal for applications in chemical processing where large volumes of liquids need to be filtered quickly and effectively. By using Ultipleat High Flow Filters, chemical processing plants can ensure that their products meet the required specifications and standards consistently.

One of the key advantages of Ultipleat High Flow Filters is their ability to remove contaminants and impurities from liquids with high efficiency. This is crucial in chemical processing, where even trace amounts of impurities can have a significant impact on product quality. By using Ultipleat High Flow Filters, chemical processing plants can achieve the desired level of purity in their products, leading to improved quality and consistency.

Furthermore, Ultipleat High Flow Filters are designed to be durable and long-lasting, making them a cost-effective solution for chemical processing plants. With proper maintenance and care, Ultipleat High Flow Filters can provide reliable filtration performance over an extended period, reducing the need for frequent replacements and minimizing downtime. This not only helps to improve operational efficiency but also contributes to overall cost savings for chemical processing plants.

In addition to their filtration efficiency and durability, Ultipleat High Flow Filters offer versatility in terms of application. They can be used in a wide range of chemical processing operations, from removing particulates and contaminants in raw materials to ensuring the purity of final products. This flexibility makes Ultipleat High Flow Filters a valuable asset for chemical processing plants looking to enhance product quality and consistency across different stages of production.

Moreover, Ultipleat High Flow Filters are easy to install and maintain, requiring minimal training and resources. This simplifies the integration of Ultipleat High Flow Filters into existing chemical processing systems, allowing for seamless operation and minimal disruption to production processes. With Ultipleat High Flow Filters, chemical processing plants can streamline their filtration operations and focus on delivering high-quality products to their customers.

Overall, Ultipleat High Flow Filters have proven to be a reliable and effective solution for enhancing product quality and consistency in chemical processing. Their high filtration efficiency, durability, versatility, and ease of use make them a preferred choice for many chemical processing plants looking to optimize their filtration processes. By incorporating Ultipleat High Flow Filters into their operations, chemical processing plants can ensure that their products meet the required standards and specifications consistently, leading to improved customer satisfaction and business success.