Choosing the Best Bag for Rosin Pressing: Material and Micron Guide

Bag Material Types for Rosin Pressing

When it comes to rosin pressing, the choice of bag material is crucial for achieving optimal results. The material of the bag not only influences the quality of the extracted rosin but also affects the efficiency of the pressing process. Various materials are available, each with distinct properties that cater to different needs and preferences. Understanding these materials is essential for anyone looking to maximize their rosin yield and quality.

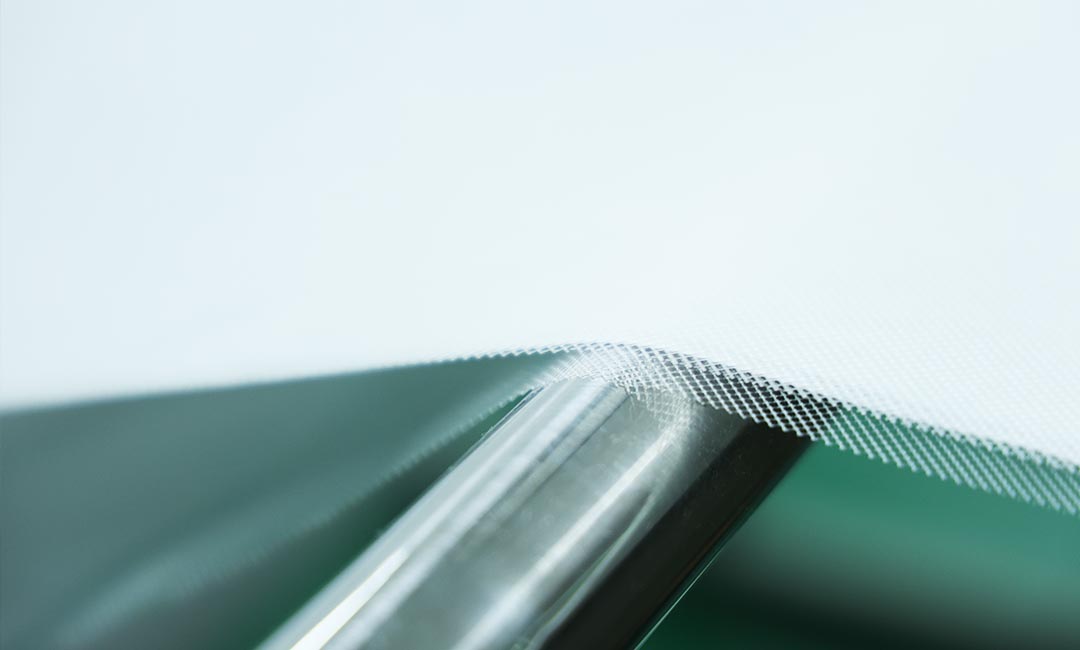

One of the most commonly used materials for rosin pressing bags is nylon. Renowned for its durability and resistance to heat, nylon bags can withstand the high temperatures involved in the pressing process without compromising their structural integrity. This characteristic makes nylon an excellent choice for those who prioritize longevity and reliability in their equipment. Additionally, nylon bags are often designed with a fine mesh, allowing for efficient filtration while preventing plant material from contaminating the final product. However, it is important to note that not all nylon bags are created equal; the quality of the nylon can vary significantly between manufacturers, which can impact the overall performance of the bag.

Another popular option is polypropylene, a material known for its lightweight and flexible nature. Polypropylene bags are often favored for their affordability and ease of use. They are less prone to tearing compared to other materials, making them suitable for those who may be new to rosin pressing or who require a more forgiving option. However, while polypropylene bags can be effective, they may not offer the same level of heat resistance as nylon, which could lead to potential issues during high-temperature extractions. Therefore, users should consider their specific pressing conditions when opting for polypropylene.

In addition to nylon and polypropylene, there are also specialized bags made from polyester. Polyester bags are particularly valued for their ability to maintain structural integrity under pressure, making them ideal for high-yield extractions. The material’s resistance to stretching and tearing ensures that the bag can handle the demands of the pressing process without compromising the quality of the rosin. Furthermore, polyester bags often feature a tighter weave, which can enhance filtration and result in a cleaner final product. However, users should be aware that polyester may not be as heat-resistant as nylon, so careful temperature management is essential when using these bags.

Moreover, some manufacturers have begun to produce bags with hybrid materials that combine the benefits of different fabrics. These hybrid bags aim to provide the best of both worlds, offering durability, flexibility, and heat resistance. By utilizing advanced weaving techniques and innovative materials, these bags can enhance the overall rosin extraction experience. As the market for rosin pressing continues to evolve, it is likely that we will see even more options emerge, catering to a wider range of preferences and requirements.

Ultimately, the choice of bag material for rosin pressing should be guided by individual needs, pressing conditions, and desired outcomes. Each material has its advantages and disadvantages, and understanding these nuances can significantly impact the quality and yield of the extracted rosin. By carefully considering the properties of nylon, polypropylene, polyester, and hybrid options, users can make informed decisions that align with their specific rosin pressing goals. As the art of rosin extraction continues to grow, so too will the innovations in bag materials, providing enthusiasts with even more tools to refine their craft.

Understanding Micron Sizes for Optimal Extraction

When it comes to rosin pressing, understanding micron sizes is crucial for achieving optimal extraction results. Micron sizes refer to the diameter of the filter mesh used in the pressing process, and they play a significant role in determining the quality and yield of the final product. The extraction of rosin involves applying heat and pressure to plant material, which releases the essential oils and cannabinoids. However, the effectiveness of this process is heavily influenced by the choice of micron size, as it directly affects the filtration of unwanted plant material and the preservation of desirable compounds.

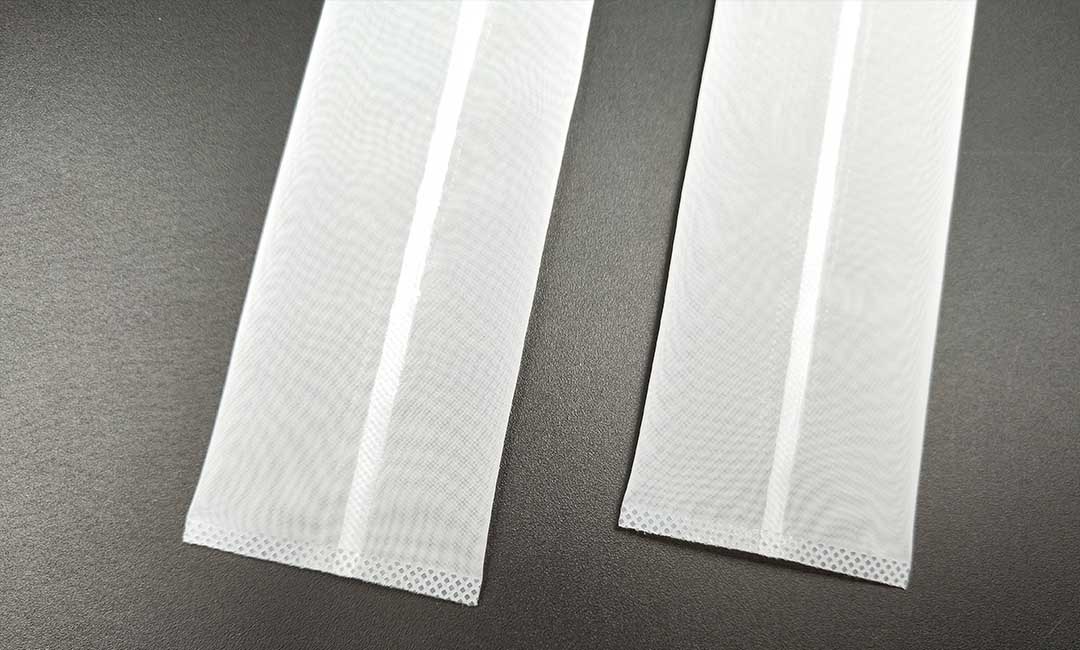

To begin with, it is essential to recognize that micron sizes are measured in micrometers, with one micron equaling one-millionth of a meter. In the context of rosin pressing, the most commonly used micron sizes range from 25 to 160 microns. Each size serves a specific purpose and can yield different results. For instance, bags with a micron size of 25 to 37 are often favored for their ability to filter out the smallest particles, resulting in a cleaner and more refined product. This size is particularly beneficial for high-quality flower or hash, as it allows for the extraction of pure rosin while minimizing the presence of plant material.

Conversely, larger micron sizes, such as 90 to 160 microns, are typically used for pressing lower-quality material or for achieving higher yields. While these larger sizes may allow more plant material to pass through, they can also result in a more robust extraction, capturing a broader spectrum of cannabinoids and terpenes. This can be advantageous for those seeking a more potent product, as the larger micron sizes can facilitate a greater volume of extraction. However, it is important to note that this may come at the cost of purity, as the final product may contain more impurities and undesirable plant matter.

Moreover, the choice of micron size should also take into account the type of material being pressed. For example, when working with fresh-frozen material, a smaller micron size is often recommended to ensure that the delicate trichomes are preserved and that the final product is of the highest quality. On the other hand, when pressing dry material, a larger micron size may be more appropriate, as it can help to increase yield without compromising too much on quality. This adaptability in choosing micron sizes allows for a tailored approach to rosin pressing, enabling extractors to optimize their results based on the specific characteristics of the material at hand.

In addition to the micron size, the material of the bag itself also plays a significant role in the extraction process. High-quality, durable materials are essential for withstanding the heat and pressure involved in rosin pressing. Bags made from nylon or polyester are commonly used due to their strength and resistance to tearing. Furthermore, the weave of the fabric can influence the flow rate of the extraction, making it important to select a bag that complements the chosen micron size.

Ultimately, understanding micron sizes is a fundamental aspect of successful rosin pressing. By carefully selecting the appropriate micron size based on the material being used and the desired outcome, extractors can significantly enhance both the quality and yield of their rosin. This knowledge, combined with the right bag material, empowers individuals to achieve optimal extraction results, ensuring that they can enjoy the full spectrum of benefits that rosin has to offer.

Comparing Nylon vs. Polyester Bags for Rosin

When it comes to rosin pressing, the choice of bag material plays a crucial role in determining the quality and yield of the final product. Among the most popular materials used for rosin bags are nylon and polyester, each offering distinct advantages and disadvantages that can significantly impact the pressing process. Understanding these differences is essential for anyone looking to optimize their rosin extraction.

Nylon bags are often favored for their durability and strength. They are designed to withstand high pressures and temperatures, making them suitable for the intense conditions of rosin pressing. The inherent elasticity of nylon allows it to stretch without tearing, which is particularly beneficial when dealing with larger quantities of material. Additionally, nylon bags typically have a smoother surface, which can facilitate the flow of rosin during extraction. This characteristic can lead to a more efficient pressing process, as the rosin is less likely to become trapped within the fibers of the bag. However, it is important to note that nylon bags can be more expensive than their polyester counterparts, which may be a consideration for those on a budget.

On the other hand, polyester bags present a more cost-effective option for rosin pressing. While they may not possess the same level of durability as nylon, polyester bags are still capable of handling moderate pressures and temperatures. They are often lighter and more flexible, which can make them easier to work with, especially for those who are new to the rosin pressing process. Furthermore, polyester bags are generally resistant to chemicals and moisture, which can be advantageous in maintaining the integrity of the material being pressed. However, the trade-off for this affordability is that polyester bags may not perform as well under extreme conditions, potentially leading to a lower yield or compromised quality in the final product.

When comparing the micron ratings of nylon and polyester bags, it is essential to consider the specific needs of the rosin pressing process. Micron ratings indicate the size of the filter mesh, which directly affects the filtration of plant material during extraction. Both nylon and polyester bags are available in a range of micron sizes, allowing users to select the appropriate bag for their desired outcome. For instance, a lower micron rating will result in a finer filtration, capturing more of the plant’s essential oils and terpenes, while a higher micron rating may allow for a quicker extraction process with less filtration. Therefore, the choice of micron size should align with the user’s goals, whether they prioritize yield, purity, or flavor.

In conclusion, the decision between nylon and polyester bags for rosin pressing ultimately depends on individual preferences and specific requirements. Nylon bags offer superior durability and efficiency, making them ideal for those who prioritize quality and are willing to invest in their equipment. Conversely, polyester bags provide a more budget-friendly option that still delivers satisfactory results for those who may be experimenting with rosin pressing or working with smaller quantities. By carefully considering the material properties, micron ratings, and personal goals, users can make an informed choice that enhances their rosin extraction experience. Ultimately, the right bag can make a significant difference in achieving the desired quality and yield, ensuring a successful rosin pressing endeavor.

Tips for Selecting the Right Bag for Your Needs

When it comes to rosin pressing, selecting the right bag is crucial for achieving optimal results. The choice of bag can significantly influence the quality and yield of the rosin extracted from your material. Therefore, understanding the various factors that contribute to the effectiveness of a pressing bag is essential. One of the primary considerations is the material of the bag itself. Typically, rosin bags are made from nylon or polyester, both of which offer durability and resistance to heat. Nylon bags are often favored for their strength and ability to withstand high pressures, while polyester bags are known for their affordability and effectiveness. It is important to assess your specific needs and preferences when deciding between these materials, as each has its own advantages.

In addition to material, the micron size of the bag plays a pivotal role in the extraction process. Micron sizes refer to the diameter of the filter mesh openings, which can range from 25 to 160 microns. A smaller micron size, such as 25 or 37 microns, is ideal for extracting finer, more potent rosin, as it allows only the smallest particles to pass through. Conversely, larger micron sizes, such as 90 or 120 microns, may be more suitable for coarser materials, as they allow for a higher yield while still filtering out unwanted plant matter. Therefore, it is essential to consider the type of material you are pressing and the desired outcome when selecting the appropriate micron size.

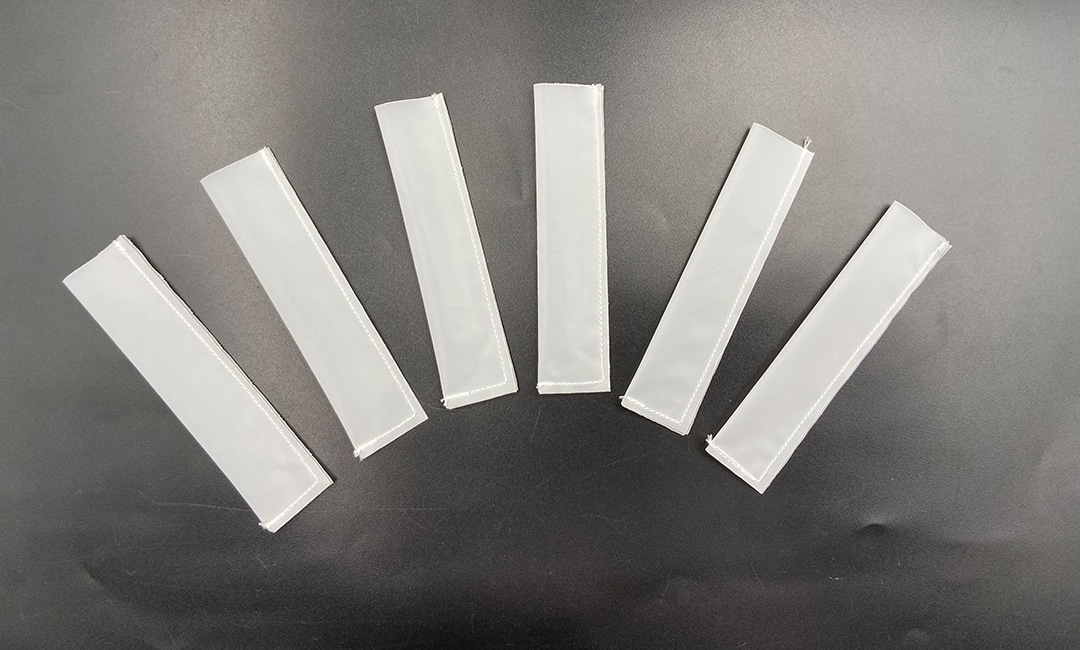

Moreover, the volume of material you intend to press should also influence your choice of bag. Bags come in various sizes, and selecting one that accommodates your pressing needs is vital. A bag that is too small may lead to overpacking, which can result in uneven pressure distribution and suboptimal extraction. On the other hand, a bag that is excessively large may not provide the necessary pressure to extract the rosin effectively. Therefore, it is advisable to choose a bag that matches the quantity of material you plan to process, ensuring that it fits comfortably within the press.

Another important aspect to consider is the bag’s stitching and construction. High-quality bags typically feature reinforced seams and double stitching, which enhance their durability and prevent tearing during the pressing process. Investing in well-constructed bags can save you time and money in the long run, as they are less likely to fail under pressure. Additionally, some bags come with a pre-wash treatment to remove any contaminants, which can further improve the purity of the final product. Therefore, examining the construction quality of the bag is a prudent step in your selection process.

Finally, it is beneficial to seek recommendations and reviews from other users in the rosin pressing community. Engaging with experienced individuals can provide valuable insights into the performance of different bags and help you make an informed decision. Online forums, social media groups, and product reviews can serve as excellent resources for gathering information about the best bags available on the market. By taking the time to research and consider these factors, you can confidently select the right bag for your rosin pressing needs, ultimately enhancing the quality and efficiency of your extraction process. In conclusion, the right bag can make a significant difference in your rosin pressing experience, so it is essential to choose wisely.