Choosing the Best High Flow Pleated Cartridge for Your Needs

Benefits of High Flow Pleated Cartridges

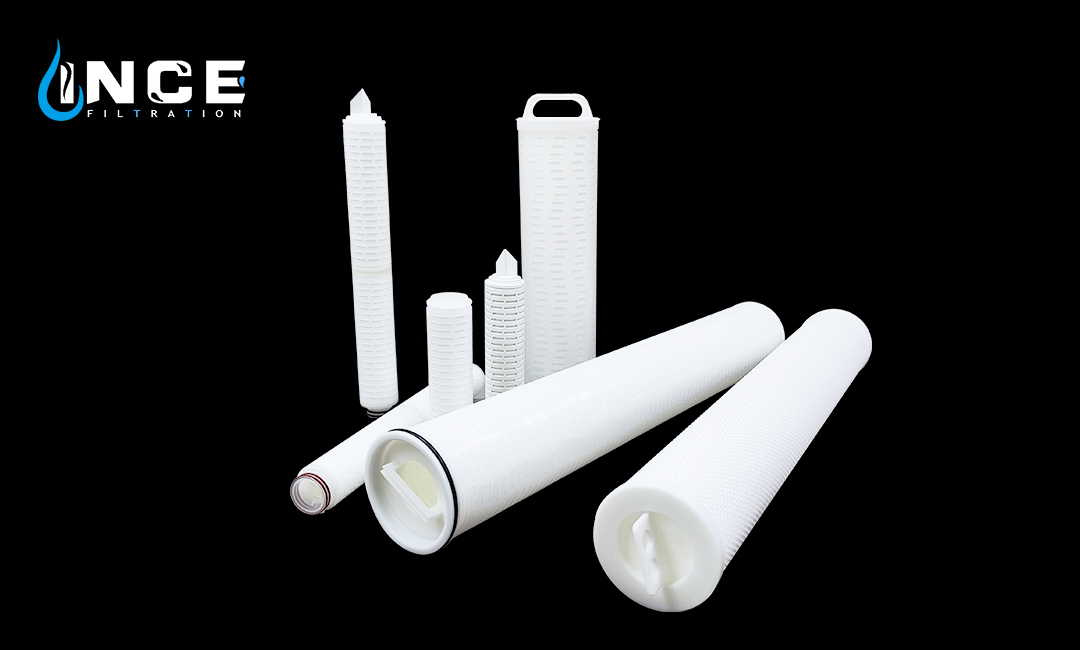

High flow pleated cartridges are an essential component in many industrial and commercial filtration systems. These cartridges are designed to handle high flow rates while effectively removing contaminants from liquids. Choosing the best high flow pleated cartridge for your specific needs is crucial to ensuring optimal filtration performance and efficiency.

One of the key benefits of high flow pleated cartridges is their ability to handle a large volume of liquid flow. This makes them ideal for applications where high flow rates are required, such as in water treatment plants, chemical processing facilities, and food and beverage production. The pleated design of these cartridges provides a large surface area for filtration, allowing for greater dirt-holding capacity and longer service life.

Another advantage of high flow pleated cartridges is their superior filtration efficiency. The pleated design creates a tortuous path for the liquid to flow through, trapping contaminants and particles along the way. This results in cleaner, clearer liquid output with reduced levels of impurities. High flow pleated cartridges are available in a variety of micron ratings to suit different filtration needs, from coarse to fine filtration.

In addition to their high flow rate and filtration efficiency, high flow pleated cartridges are also easy to install and replace. Most cartridges are designed to fit standard filter housings, making them compatible with a wide range of filtration systems. This makes it simple to upgrade or replace cartridges as needed, without the need for specialized tools or equipment.

When choosing the best high flow pleated cartridge for your needs, there are several factors to consider. The first is the micron rating of the cartridge, which determines the size of particles that can be effectively removed. For applications requiring fine filtration, a lower micron rating is recommended, while coarser filtration may require a higher micron rating.

Another important factor to consider is the material of the cartridge. High flow pleated cartridges are available in a variety of materials, including polypropylene, polyester, and nylon. The choice of material will depend on the specific requirements of your application, such as chemical compatibility, temperature resistance, and durability.

It is also important to consider the flow rate and pressure rating of the cartridge. High flow pleated cartridges are designed to handle a specific flow rate and pressure range, so it is essential to choose a cartridge that is compatible with your system’s requirements. Selecting a cartridge with a higher flow rate and pressure rating than needed can result in reduced filtration efficiency and increased operating costs.

In conclusion, high flow pleated cartridges offer numerous benefits for industrial and commercial filtration applications. Their high flow rate, superior filtration efficiency, and ease of installation make them an ideal choice for a wide range of applications. When choosing the best high flow pleated cartridge for your needs, consider factors such as micron rating, material, flow rate, and pressure rating to ensure optimal filtration performance and efficiency.

Factors to Consider When Choosing a High Flow Pleated Cartridge

When it comes to choosing the best high flow pleated cartridge for your needs, there are several factors to consider. High flow pleated cartridges are commonly used in industrial and commercial applications to filter large volumes of liquid at a fast rate. These cartridges are designed to handle high flow rates while maintaining efficiency and durability. In order to select the right high flow pleated cartridge for your specific application, it is important to take into account a few key factors.

One of the most important factors to consider when choosing a high flow pleated cartridge is the filtration efficiency. The filtration efficiency of a cartridge is determined by its pore size and surface area. Cartridges with smaller pore sizes and larger surface areas are more effective at removing contaminants from the liquid. It is important to select a cartridge with the appropriate filtration efficiency for your specific application in order to achieve the desired level of filtration.

Another factor to consider when choosing a high flow pleated cartridge is the material of construction. High flow pleated cartridges are typically made from a variety of materials, including polypropylene, polyester, and cellulose. Each material has its own unique properties and is suitable for different applications. It is important to select a cartridge made from a material that is compatible with the liquid being filtered and can withstand the operating conditions of your system.

In addition to filtration efficiency and material of construction, it is also important to consider the flow rate and pressure drop of the cartridge. High flow pleated cartridges are designed to handle large volumes of liquid at a fast rate, but the flow rate and pressure drop of the cartridge can vary depending on the design and construction of the cartridge. It is important to select a cartridge that can handle the flow rate and pressure drop requirements of your system in order to ensure optimal performance.

Furthermore, it is important to consider the size and configuration of the cartridge. High flow pleated cartridges come in a variety of sizes and configurations, including single open end, double open end, and single closed end. The size and configuration of the cartridge can impact its compatibility with your system and its ease of installation. It is important to select a cartridge that is the right size and configuration for your specific application in order to ensure a proper fit and optimal performance.

In conclusion, choosing the best high flow pleated cartridge for your needs requires careful consideration of several key factors. By taking into account factors such as filtration efficiency, material of construction, flow rate and pressure drop, and size and configuration, you can select a cartridge that is well-suited to your specific application. It is important to consult with a filtration expert or supplier to help guide you through the selection process and ensure that you choose the right high flow pleated cartridge for your needs.

Top Brands and Models of High Flow Pleated Cartridges

When it comes to choosing the best high flow pleated cartridge for your needs, there are several top brands and models to consider. These cartridges are designed to provide efficient filtration for a wide range of applications, from industrial to residential. In this article, we will explore some of the top brands and models of high flow pleated cartridges on the market today.

One of the top brands in the high flow pleated cartridge industry is Pall Corporation. Pall offers a wide range of high flow pleated cartridges that are designed to provide superior filtration performance. Their cartridges are made from high-quality materials and are designed to withstand high flow rates and high temperatures. Some of the top models from Pall include the Ultipleat High Flow Filter and the Profile Core High Flow Filter.

Another top brand in the high flow pleated cartridge industry is Parker Hannifin. Parker Hannifin offers a variety of high flow pleated cartridges that are designed to provide efficient filtration for a wide range of applications. Their cartridges are known for their durability and reliability, making them a top choice for many customers. Some of the top models from Parker Hannifin include the Finite High Flow Filter and the Par-Fit High Flow Filter.

One of the key factors to consider when choosing a high flow pleated cartridge is the filtration efficiency. The filtration efficiency of a cartridge is determined by its pore size and surface area. Cartridges with smaller pore sizes and larger surface areas are able to capture more contaminants and provide better filtration performance. When choosing a high flow pleated cartridge, it is important to consider the specific requirements of your application and select a cartridge that offers the right balance of filtration efficiency and flow rate.

In addition to filtration efficiency, it is also important to consider the flow rate of the cartridge. High flow pleated cartridges are designed to handle high flow rates, making them ideal for applications where a large volume of fluid needs to be filtered quickly. When choosing a high flow pleated cartridge, it is important to select a model that can handle the flow rate of your application without causing a drop in pressure or flow rate.

Another important factor to consider when choosing a high flow pleated cartridge is the material of construction. Cartridges are typically made from a variety of materials, including polypropylene, polyester, and fiberglass. The material of construction can impact the durability and performance of the cartridge, so it is important to choose a cartridge that is made from a material that is compatible with your application.

In conclusion, when choosing the best high flow pleated cartridge for your needs, it is important to consider factors such as filtration efficiency, flow rate, and material of construction. By selecting a high-quality cartridge from a top brand such as Pall Corporation or Parker Hannifin, you can ensure that you are getting a reliable and efficient filtration solution for your application.

How to Properly Maintain and Replace High Flow Pleated Cartridges

High flow pleated cartridges are essential components in many industrial and commercial filtration systems. They are designed to handle high flow rates while effectively removing contaminants from liquids. However, like all filtration components, high flow pleated cartridges require proper maintenance and replacement to ensure optimal performance. In this article, we will discuss how to properly maintain and replace high flow pleated cartridges to help you choose the best option for your specific needs.

Regular maintenance is key to ensuring the longevity and efficiency of high flow pleated cartridges. One of the most important maintenance tasks is regular cleaning. Over time, contaminants can build up on the surface of the pleats, reducing the cartridge’s effectiveness. To clean a high flow pleated cartridge, simply remove it from the filtration system and rinse it with clean water. For more stubborn contaminants, a mild detergent or cleaning solution may be necessary. Be sure to follow the manufacturer’s guidelines for cleaning to avoid damaging the cartridge.

In addition to regular cleaning, it is important to monitor the pressure drop across the cartridge. A sudden increase in pressure drop may indicate that the cartridge is becoming clogged and needs to be replaced. Monitoring the pressure drop can help you determine the optimal replacement schedule for your specific filtration system.

When it comes time to replace a high flow pleated cartridge, it is important to choose the right replacement for your needs. There are several factors to consider when selecting a replacement cartridge, including the filtration efficiency, flow rate, and compatibility with your filtration system. It is important to choose a cartridge that is designed to handle the specific contaminants present in your liquid stream.

One of the most important factors to consider when choosing a replacement cartridge is the filtration efficiency. High flow pleated cartridges are available in a variety of filtration ratings, ranging from coarse to fine. The filtration rating you choose will depend on the size and type of contaminants you need to remove from your liquid stream. For example, if you are filtering out large particles, a coarse filtration rating may be sufficient. However, if you need to remove smaller particles or microorganisms, a finer filtration rating may be necessary.

Another important factor to consider when choosing a replacement cartridge is the flow rate. High flow pleated cartridges are designed to handle high flow rates, but it is important to choose a cartridge that can handle the specific flow rate of your filtration system. Choosing a cartridge with a flow rate that is too low can result in reduced filtration efficiency, while choosing a cartridge with a flow rate that is too high can put unnecessary strain on your filtration system.

Finally, it is important to ensure that the replacement cartridge is compatible with your filtration system. High flow pleated cartridges come in a variety of sizes and configurations, so it is important to choose a cartridge that fits your system’s specifications. Be sure to consult the manufacturer’s guidelines and specifications when selecting a replacement cartridge to ensure compatibility.

In conclusion, proper maintenance and replacement of high flow pleated cartridges are essential for ensuring the efficiency and longevity of your filtration system. By following the tips outlined in this article, you can choose the best high flow pleated cartridge for your specific needs and ensure optimal performance of your filtration system.