Choosing the Optimal Rosin Press Bag Size for Your Plates

Understanding Rosin Press Bag Sizes

When it comes to extracting rosin, the choice of bag size is a critical factor that can significantly influence the quality and yield of the final product. Understanding the various sizes of rosin press bags available on the market is essential for both novice and experienced users alike. The size of the bag you choose will depend on several factors, including the size of your plates, the amount of material you intend to process, and the specific characteristics of the material itself.

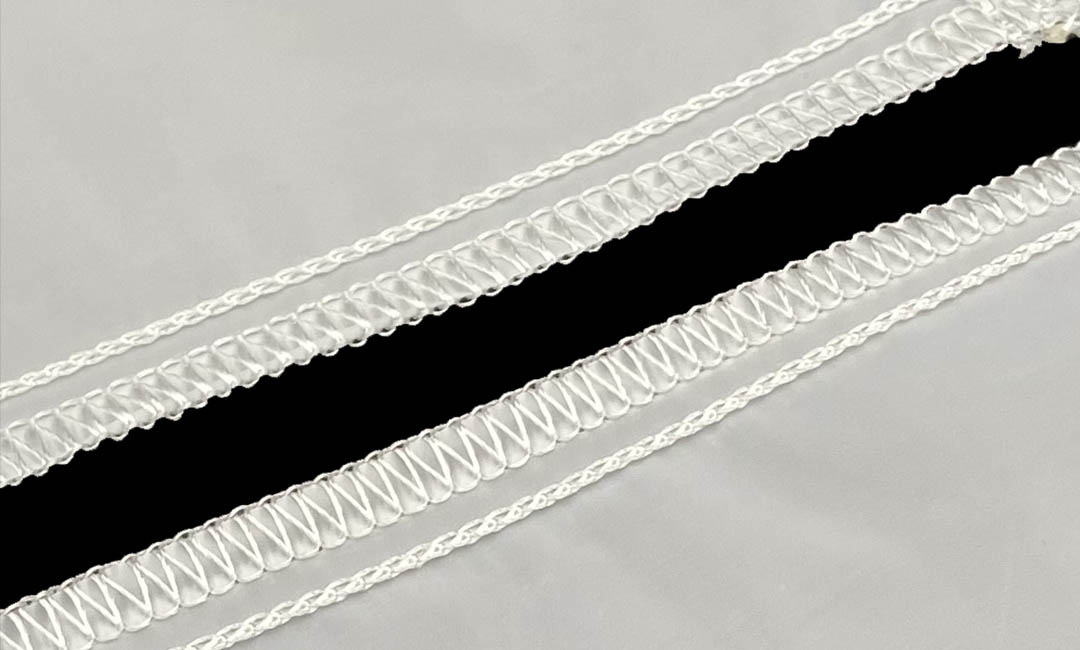

To begin with, rosin press bags come in a range of sizes, typically measured in microns, which indicates the size of the mesh openings. The most common sizes are 25, 37, 90, and 160 microns, each serving a distinct purpose in the extraction process. Smaller micron bags, such as those measuring 25 microns, are ideal for finer materials, as they allow for the extraction of high-quality rosin while filtering out unwanted plant material. Conversely, larger micron bags, like those at 160 microns, are better suited for coarser materials, as they facilitate a quicker extraction process but may yield a product with more impurities.

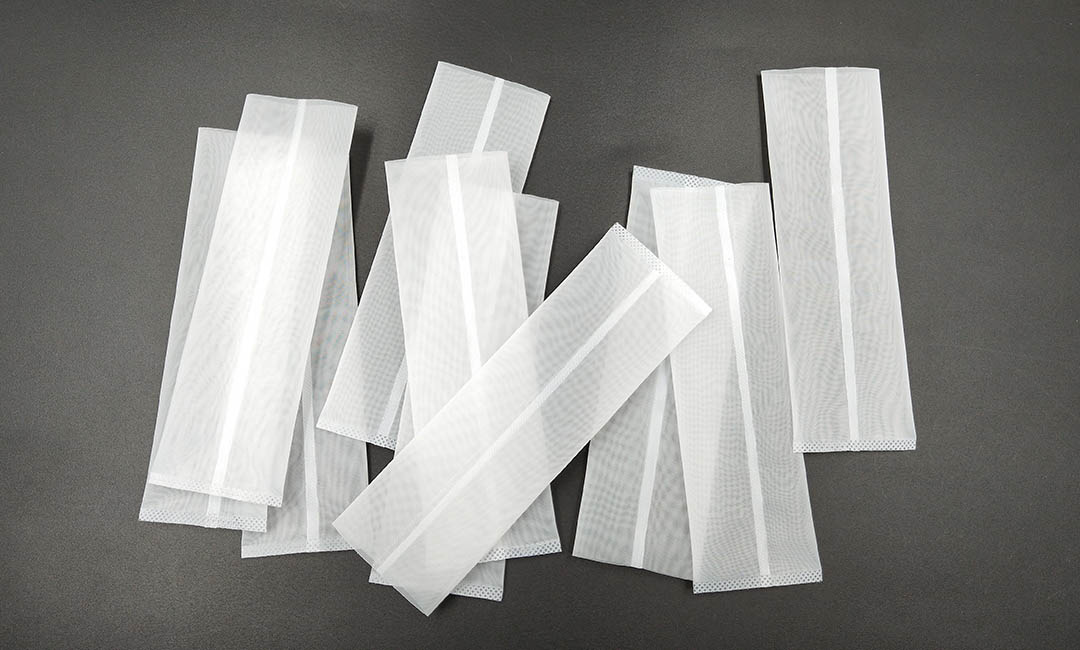

In addition to micron size, the physical dimensions of the bag are equally important. Rosin press bags are available in various sizes, ranging from small bags designed for personal use to larger bags suitable for commercial operations. When selecting a bag size, it is crucial to consider the dimensions of your rosin press plates. A bag that is too small may not fit properly, leading to inefficient extraction and potential damage to the bag itself. On the other hand, a bag that is excessively large may result in wasted material and a less concentrated yield.

Moreover, the amount of material you plan to process plays a significant role in determining the optimal bag size. For small batches, a smaller bag may suffice, allowing for a more controlled extraction process. However, if you are working with larger quantities, it is advisable to opt for a larger bag that can accommodate the volume without compromising the quality of the extraction. This balance between bag size and material quantity is essential for maximizing yield while maintaining the integrity of the rosin.

Furthermore, the type of material being processed can also influence your choice of bag size. Different strains of cannabis or other botanicals may have varying levels of moisture and oil content, which can affect how they respond to heat and pressure during extraction. For instance, denser materials may require a smaller micron size to ensure that the rosin is adequately filtered, while lighter, fluffier materials may benefit from a larger micron size that allows for a more efficient flow of oil.

In conclusion, selecting the optimal rosin press bag size involves a careful consideration of several factors, including micron size, physical dimensions, material quantity, and the specific characteristics of the material being processed. By understanding these elements, users can make informed decisions that enhance the quality and yield of their rosin extraction. Ultimately, the right bag size not only improves the efficiency of the extraction process but also contributes to the overall satisfaction with the final product. As you embark on your rosin extraction journey, taking the time to choose the appropriate bag size will undoubtedly pay dividends in the quality of your results.

Factors to Consider When Selecting Bag Size

When selecting the optimal rosin press bag size for your plates, several factors come into play that can significantly influence the quality and yield of your extraction process. Understanding these factors is essential for achieving the best results, as the right bag size can enhance efficiency and improve the overall experience of rosin extraction.

First and foremost, the size of the plates in your rosin press is a critical consideration. The dimensions of the plates dictate the maximum size of the rosin press bag you can use. It is essential to ensure that the bag fits comfortably within the plates without excessive overlap or bunching, as this can lead to uneven pressure distribution during the pressing process. A bag that is too large may not allow for optimal extraction, while one that is too small can restrict the material and hinder the flow of rosin. Therefore, measuring your plates accurately and selecting a bag that complements these dimensions is the first step in the decision-making process.

In addition to plate size, the amount and type of material you intend to press also play a significant role in determining the appropriate bag size. Different materials, such as flower, kief, or hash, have varying densities and moisture content, which can affect how they expand during pressing. For instance, if you are working with a denser material, you may require a larger bag to accommodate the expansion and ensure that the material does not become overly compacted. Conversely, lighter materials may necessitate a smaller bag to prevent excessive movement and ensure that the rosin is efficiently extracted. Thus, understanding the characteristics of your starting material is crucial for selecting the right bag size.

Moreover, the desired yield is another important factor to consider. If you are aiming for a higher yield, using a larger bag may be beneficial, as it allows for more material to be processed simultaneously. However, it is essential to strike a balance; overloading a bag can lead to suboptimal extraction and may result in lower-quality rosin. Therefore, it is advisable to consider your yield goals in conjunction with the other factors mentioned, ensuring that you do not compromise quality for quantity.

Furthermore, the micron size of the rosin press bag is an aspect that should not be overlooked. Micron size refers to the size of the filter mesh within the bag, which determines the size of the particles that can pass through during extraction. A smaller micron size can help retain more plant material, resulting in a cleaner and more potent product. However, it is essential to match the micron size with the bag dimensions and the type of material being pressed. For example, using a smaller micron bag with a larger amount of material may lead to clogging, which can hinder the extraction process.

Lastly, personal preference and experience also play a role in selecting the optimal bag size. As you gain more experience with rosin extraction, you may develop a better understanding of how different bag sizes affect your results. Experimenting with various sizes can provide valuable insights into what works best for your specific setup and material types. In conclusion, by carefully considering the size of your plates, the type and amount of material, desired yield, micron size, and your own experience, you can make an informed decision when selecting the optimal rosin press bag size for your plates, ultimately enhancing your rosin extraction process.

Common Mistakes in Choosing Rosin Press Bags

When it comes to extracting rosin, the choice of rosin press bag size is crucial for achieving optimal results. However, many individuals make common mistakes that can hinder their extraction process. One prevalent error is selecting a bag size that does not correspond to the size of the plates being used. It is essential to understand that the dimensions of the rosin press bag should align with the plates to ensure an efficient extraction. If the bag is too small, it may not accommodate the material properly, leading to uneven pressure distribution and subpar yields. Conversely, using a bag that is excessively large can result in wasted space and inefficient extraction, as the material may not be adequately compressed.

Another frequent mistake is overlooking the thickness of the rosin press bag. While many users focus solely on the size, the thickness of the bag plays a significant role in the extraction process. Thicker bags can withstand higher pressures, which is particularly important for those who are working with denser materials. However, if the bag is too thick for the specific extraction being performed, it may impede the flow of rosin, resulting in lower yields. Therefore, it is vital to strike a balance between size and thickness to ensure that the bag can handle the pressure while allowing for optimal resin flow.

In addition to size and thickness, many users fail to consider the type of material being extracted when choosing a rosin press bag. Different materials have varying characteristics that can affect the extraction process. For instance, when working with flower, a bag with a larger micron size may be appropriate, as it allows for the passage of larger particles while still capturing the essential oils. On the other hand, when extracting from hash or kief, a smaller micron size is often recommended to ensure that only the finest particles are collected. Neglecting to match the bag’s micron size to the material can lead to contamination and reduced quality of the final product.

Moreover, some individuals underestimate the importance of pre-pressing their material before placing it in the rosin press bag. Failing to pre-press can result in uneven distribution of the material within the bag, which can lead to inconsistent pressure during extraction. This inconsistency can ultimately affect the quality and quantity of the rosin produced. By pre-pressing the material, users can create a more uniform puck that fits snugly within the bag, allowing for better compression and more efficient extraction.

Lastly, it is essential to consider the number of bags being used during the extraction process. Some users mistakenly believe that using multiple bags will enhance their yields. However, this can often lead to complications, such as increased chances of bag rupture or difficulty in managing the extraction process. Instead, focusing on the right size and quality of a single bag can yield better results than attempting to use multiple bags simultaneously.

In conclusion, choosing the optimal rosin press bag size involves careful consideration of several factors, including the size and thickness of the bag, the type of material being extracted, and the importance of pre-pressing. By avoiding these common mistakes, users can enhance their extraction process, leading to higher yields and better-quality rosin. Understanding these nuances will ultimately contribute to a more successful and satisfying rosin extraction experience.

Benefits of Using the Right Bag Size for Your Plates

When it comes to extracting rosin, the size of the press bag you choose plays a crucial role in determining the quality and yield of your final product. Selecting the optimal rosin press bag size for your plates can significantly enhance the efficiency of the extraction process, leading to better results. One of the primary benefits of using the right bag size is that it allows for a more uniform distribution of material within the press. When the bag is appropriately sized, the plant material can be evenly spread out, ensuring that heat and pressure are applied uniformly. This uniformity is essential because it helps to maximize the extraction of essential oils and cannabinoids, resulting in a higher yield of rosin.

Moreover, using the correct bag size minimizes the risk of blowouts during the pressing process. A bag that is too small may become overfilled, leading to excessive pressure that can cause the bag to rupture. Conversely, a bag that is too large may allow the material to shift, resulting in uneven extraction and wasted product. By choosing a bag that fits your plates snugly, you can maintain control over the extraction process, thereby reducing the likelihood of mishaps and ensuring a cleaner, more efficient operation.

In addition to improving yield and reducing blowouts, the right bag size can also enhance the overall quality of the rosin produced. When the material is properly contained within the bag, it is less likely to come into contact with contaminants or foreign materials that could compromise the purity of the final product. This is particularly important for those who prioritize quality and are looking to produce rosin that is free from impurities. Furthermore, a well-sized bag can help to retain the terpenes and flavors of the plant material, resulting in a more aromatic and flavorful end product.

Another significant advantage of using the correct bag size is that it can streamline the extraction process. When the bag fits well within the plates, it allows for easier handling and manipulation during pressing. This efficiency can save time and effort, making the entire process more enjoyable and less labor-intensive. Additionally, a properly sized bag can facilitate better drainage of the rosin, allowing for a quicker and more effective collection of the final product. This efficiency not only enhances the user experience but also contributes to a more productive workflow.

Furthermore, using the right bag size can lead to cost savings in the long run. By maximizing yield and minimizing waste, you can make the most of your starting material, ultimately reducing the amount of product you need to purchase. This is particularly beneficial for those who are operating on a budget or looking to optimize their resources. In essence, the right bag size not only improves the quality and quantity of your rosin but also enhances the overall efficiency of the extraction process.

In conclusion, the benefits of choosing the optimal rosin press bag size for your plates are manifold. From maximizing yield and ensuring quality to streamlining the extraction process and reducing costs, the right bag size is an essential consideration for anyone serious about rosin extraction. By taking the time to select the appropriate size, you can significantly improve your results and enjoy a more successful and satisfying extraction experience.