Choosing the Right High Flow Filter Cartridge for Your Business Needs

Benefits of High Flow Filter Cartridges

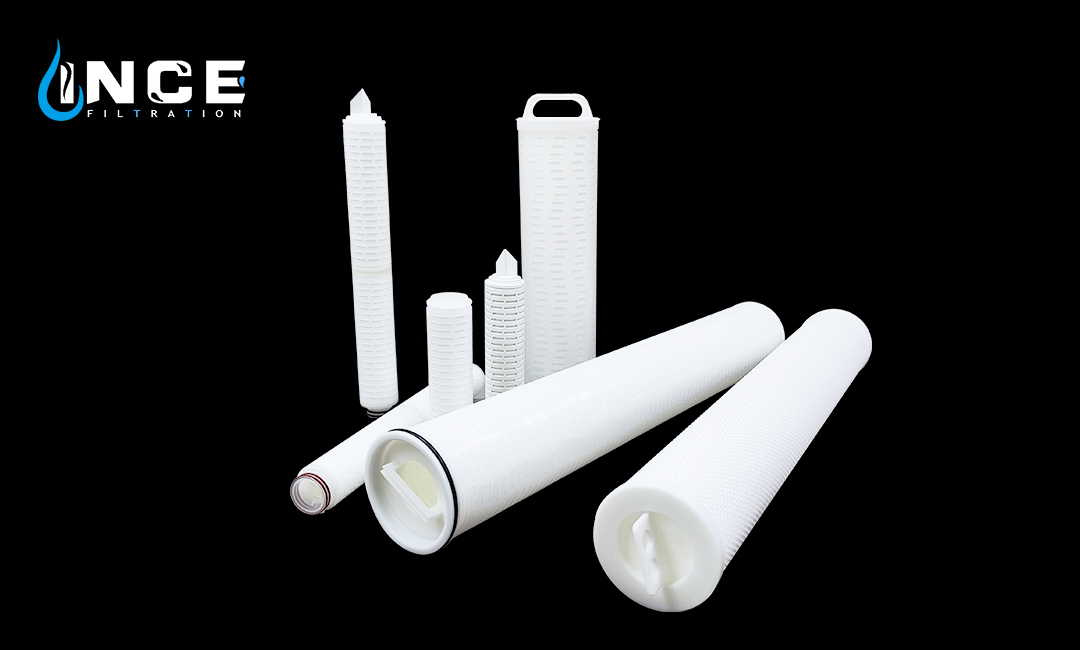

High flow filter cartridges are an essential component in many industrial and commercial applications. These filters are designed to handle high flow rates while effectively removing contaminants from liquids. Choosing the right high flow filter cartridge for your business needs is crucial to ensure optimal performance and efficiency.

One of the key benefits of high flow filter cartridges is their ability to handle large volumes of liquid flow. These filters are designed to accommodate flow rates that are significantly higher than traditional filters, making them ideal for applications where a high flow rate is required. This can help improve the overall efficiency of your operations by reducing the time and energy required to filter large volumes of liquid.

In addition to their high flow capacity, high flow filter cartridges are also known for their superior filtration efficiency. These filters are designed to remove a wide range of contaminants, including sediment, dirt, rust, and other particles that can affect the quality of your liquids. By using a high flow filter cartridge, you can ensure that your liquids are free from impurities and meet the required quality standards.

Another benefit of high flow filter cartridges is their long service life. These filters are built to withstand high flow rates and heavy use, making them a durable and reliable option for industrial and commercial applications. By choosing a high flow filter cartridge with a long service life, you can reduce the frequency of filter replacements and maintenance, saving time and money in the long run.

High flow filter cartridges are also easy to install and maintain, making them a convenient option for businesses with limited resources or technical expertise. These filters are designed to be user-friendly, with simple installation procedures and easy-to-follow maintenance instructions. This can help streamline your operations and reduce downtime associated with filter maintenance and replacement.

When choosing a high flow filter cartridge for your business needs, it is important to consider the specific requirements of your application. Factors such as flow rate, filtration efficiency, service life, and compatibility with your existing equipment should all be taken into account when selecting a filter cartridge. Consulting with a filtration expert can help you determine the best high flow filter cartridge for your specific needs.

In conclusion, high flow filter cartridges offer a range of benefits for businesses looking to improve the efficiency and performance of their operations. These filters are designed to handle high flow rates, provide superior filtration efficiency, and offer a long service life. By choosing the right high flow filter cartridge for your business needs, you can ensure that your liquids are free from contaminants and meet the required quality standards. Consider the specific requirements of your application and consult with a filtration expert to find the best high flow filter cartridge for your business.

Factors to Consider When Choosing a High Flow Filter Cartridge

When it comes to selecting the right high flow filter cartridge for your business needs, there are several factors to consider. High flow filter cartridges are essential components in many industrial processes, helping to remove contaminants and impurities from liquids and gases. Choosing the right filter cartridge is crucial to ensuring the efficiency and effectiveness of your filtration system. In this article, we will discuss some key factors to consider when selecting a high flow filter cartridge for your business.

One of the first factors to consider when choosing a high flow filter cartridge is the type of contaminants you need to remove. Different filter cartridges are designed to target specific types of contaminants, such as sediment, bacteria, or chemicals. Understanding the specific contaminants present in your process stream will help you select a filter cartridge that is best suited to your needs.

Another important factor to consider is the flow rate of your filtration system. High flow filter cartridges are designed to handle large volumes of liquid or gas, so it is essential to choose a cartridge that can accommodate the flow rate of your system. Selecting a filter cartridge with the appropriate flow rate will help ensure that your filtration system operates efficiently and effectively.

The material of the filter cartridge is also an important consideration. High flow filter cartridges are available in a variety of materials, including polypropylene, polyester, and cellulose. The material of the filter cartridge will impact its compatibility with different liquids and gases, as well as its durability and lifespan. It is important to choose a filter cartridge made from a material that is compatible with the substances being filtered and that can withstand the conditions of your filtration system.

In addition to material, the size and configuration of the filter cartridge are also important factors to consider. High flow filter cartridges come in a range of sizes and configurations, including pleated, depth, and membrane filters. The size and configuration of the filter cartridge will impact its filtration efficiency and capacity. Selecting a filter cartridge with the appropriate size and configuration for your system will help ensure optimal filtration performance.

Cost is another important factor to consider when choosing a high flow filter cartridge. The cost of filter cartridges can vary significantly depending on factors such as material, size, and brand. It is important to consider not only the upfront cost of the filter cartridge but also factors such as maintenance and replacement costs. Choosing a high-quality filter cartridge that is within your budget will help ensure that your filtration system operates effectively without breaking the bank.

Finally, it is important to consider the reputation and reliability of the manufacturer when selecting a high flow filter cartridge. Working with a reputable manufacturer that has a track record of producing high-quality filter cartridges will help ensure that you are getting a reliable and effective product. Researching different manufacturers and reading customer reviews can help you make an informed decision when selecting a filter cartridge for your business.

In conclusion, choosing the right high flow filter cartridge for your business needs requires careful consideration of factors such as contaminants, flow rate, material, size, configuration, cost, and manufacturer reputation. By taking the time to evaluate these factors and select a filter cartridge that meets your specific requirements, you can ensure the efficiency and effectiveness of your filtration system.

Different Types of High Flow Filter Cartridges Available

High flow filter cartridges are essential components in many industrial processes, helping to remove contaminants and impurities from liquids and gases. When it comes to choosing the right high flow filter cartridge for your business needs, it’s important to consider the different types available on the market.

One of the most common types of high flow filter cartridges is the pleated filter cartridge. These cartridges are made from a pleated filter media that provides a large surface area for filtration. This design allows for high flow rates and efficient particle removal. Pleated filter cartridges are ideal for applications where high flow rates are required, such as in water treatment plants or industrial processes.

Another type of high flow filter cartridge is the depth filter cartridge. These cartridges are made from a thick layer of filter media that traps contaminants as the liquid or gas passes through. Depth filter cartridges are known for their high dirt-holding capacity and long service life. They are often used in applications where a high level of filtration is required, such as in pharmaceutical manufacturing or food and beverage processing.

In addition to pleated and depth filter cartridges, there are also membrane filter cartridges available. These cartridges are made from a thin membrane that provides precise filtration of particles and microorganisms. Membrane filter cartridges are commonly used in applications where sterile filtration is required, such as in the pharmaceutical and biotech industries.

When choosing a high flow filter cartridge for your business needs, it’s important to consider the specific requirements of your application. Factors such as flow rate, particle size, and contaminant type will all play a role in determining the best filter cartridge for your needs. Consulting with a filtration expert can help you determine the most suitable filter cartridge for your application.

It’s also important to consider the material of construction when choosing a high flow filter cartridge. Filter cartridges are available in a variety of materials, including polypropylene, polyester, and nylon. The material of construction will impact the compatibility of the filter cartridge with different liquids and gases, as well as its resistance to chemicals and temperature.

In conclusion, choosing the right high flow filter cartridge for your business needs is essential for maintaining the efficiency and effectiveness of your filtration system. By considering the different types of high flow filter cartridges available on the market, as well as the specific requirements of your application, you can select a filter cartridge that meets your filtration needs. Consulting with a filtration expert can help you make an informed decision and ensure that you choose the best filter cartridge for your business.

How to Properly Maintain and Replace High Flow Filter Cartridges

High flow filter cartridges are an essential component in many industrial and commercial applications. They play a crucial role in removing contaminants and impurities from liquids, ensuring that equipment and processes run smoothly and efficiently. However, in order for high flow filter cartridges to perform effectively, they must be properly maintained and replaced when necessary.

One of the most important aspects of maintaining high flow filter cartridges is ensuring that they are cleaned regularly. Over time, contaminants can build up on the surface of the filter, reducing its effectiveness and potentially causing damage to equipment downstream. Regular cleaning can help to prevent these issues and prolong the life of the filter cartridge.

When cleaning high flow filter cartridges, it is important to use the proper techniques and cleaning solutions. Harsh chemicals or abrasive cleaning methods can damage the filter media and reduce its efficiency. Instead, it is recommended to use a mild detergent and water solution to gently clean the filter cartridge. Be sure to rinse the filter thoroughly after cleaning to remove any residue.

In addition to regular cleaning, it is also important to monitor the condition of high flow filter cartridges and replace them when necessary. Over time, the filter media can become clogged with contaminants, reducing the flow rate and efficiency of the filter. This can lead to increased pressure drop, decreased filtration performance, and potential damage to equipment downstream.

To determine when a high flow filter cartridge needs to be replaced, it is important to monitor the pressure drop across the filter. An increase in pressure drop indicates that the filter is becoming clogged and may need to be replaced. Additionally, if the quality of the filtered liquid begins to deteriorate, it may be a sign that the filter cartridge is no longer effective and needs to be replaced.

When choosing a replacement high flow filter cartridge, it is important to select the right type and size for your specific application. There are a wide variety of filter cartridges available, each designed for different levels of filtration and flow rates. It is important to consider factors such as the type of contaminants being filtered, the flow rate of the liquid, and the operating conditions of the system when selecting a replacement filter cartridge.

It is also important to ensure that the replacement filter cartridge is compatible with the existing filtration system. Different filter cartridges may have different end cap configurations, sizes, and sealing mechanisms. It is important to select a replacement filter cartridge that is designed to fit your specific filtration system to ensure proper installation and performance.

In conclusion, proper maintenance and replacement of high flow filter cartridges are essential for ensuring the efficiency and effectiveness of industrial and commercial filtration systems. By following the proper cleaning techniques, monitoring the condition of the filter cartridges, and selecting the right replacement cartridges for your specific needs, you can ensure that your filtration system operates smoothly and efficiently. Remember to consult with a filtration expert if you have any questions or concerns about maintaining and replacing high flow filter cartridges in your business.