Choosing the Right High Flow Filter Cartridge for Your Industry

Benefits of Using High Flow Filter Cartridges

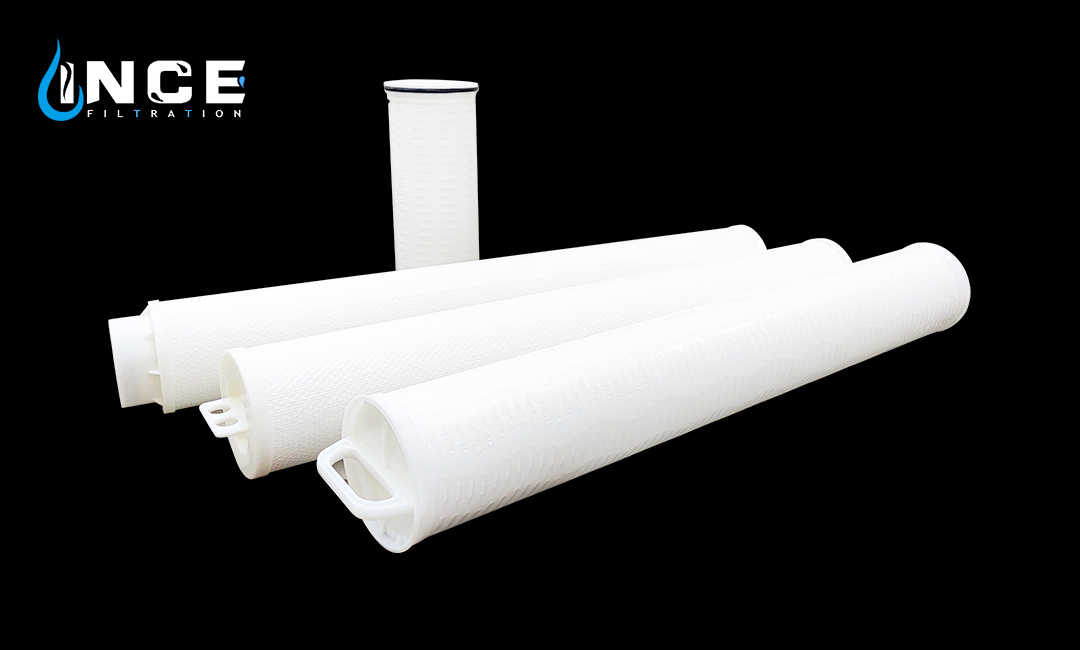

High flow filter cartridges are an essential component in many industries, helping to remove contaminants and impurities from liquids and gases. These cartridges offer numerous benefits, making them a popular choice for businesses looking to improve the quality of their products and processes. In this article, we will explore the advantages of using high flow filter cartridges and provide tips on how to choose the right one for your industry.

One of the primary benefits of high flow filter cartridges is their efficiency in removing particles from liquids and gases. These cartridges are designed to handle high flow rates, allowing for faster filtration and increased productivity. By using high flow filter cartridges, businesses can ensure that their products meet quality standards and regulations, leading to improved customer satisfaction and reduced waste.

Another advantage of high flow filter cartridges is their cost-effectiveness. These cartridges have a longer lifespan than traditional filters, reducing the need for frequent replacements and maintenance. This can result in significant cost savings for businesses over time, making high flow filter cartridges a wise investment for industries looking to improve efficiency and reduce operating costs.

In addition to their efficiency and cost-effectiveness, high flow filter cartridges are also versatile and can be customized to meet the specific needs of different industries. Whether you are in the food and beverage, pharmaceutical, or chemical industry, there is a high flow filter cartridge that can effectively remove contaminants and impurities from your products. By choosing the right cartridge for your industry, you can ensure that your filtration system operates at peak performance and delivers high-quality results.

When selecting a high flow filter cartridge for your industry, there are several factors to consider. First, you should determine the type of contaminants you need to remove from your liquids or gases. Different cartridges are designed to target specific particles, so it is essential to choose a cartridge that can effectively filter out the impurities present in your products.

You should also consider the flow rate of your filtration system when selecting a high flow filter cartridge. The flow rate will determine the size and type of cartridge you need to ensure optimal filtration efficiency. By choosing a cartridge that matches your system’s flow rate, you can maximize the performance of your filtration system and achieve the desired level of purity in your products.

In conclusion, high flow filter cartridges offer numerous benefits for industries looking to improve the quality of their products and processes. These cartridges are efficient, cost-effective, and versatile, making them a valuable investment for businesses in various sectors. By choosing the right high flow filter cartridge for your industry and considering factors such as the type of contaminants and flow rate of your system, you can ensure that your filtration system operates at peak performance and delivers high-quality results.

Factors to Consider When Selecting High Flow Filter Cartridges

High flow filter cartridges are essential components in many industries, helping to remove contaminants and impurities from liquids and gases. Choosing the right high flow filter cartridge for your industry is crucial to ensure optimal performance and efficiency. There are several factors to consider when selecting high flow filter cartridges, including the type of contaminants present, flow rate requirements, and compatibility with existing filtration systems.

One of the most important factors to consider when selecting a high flow filter cartridge is the type of contaminants that need to be removed. Different industries may have varying levels of contaminants in their liquids or gases, such as sediment, particles, or chemicals. It is essential to choose a high flow filter cartridge that is specifically designed to effectively remove the contaminants present in your industry. For example, if your industry deals with heavy sedimentation, a high flow filter cartridge with a larger pore size may be more suitable.

Another factor to consider is the flow rate requirements of your industry. High flow filter cartridges are designed to handle a higher volume of liquid or gas flow compared to standard filter cartridges. It is important to select a high flow filter cartridge that can accommodate the flow rate demands of your industry without compromising filtration efficiency. Consider factors such as pressure drop, filtration capacity, and maintenance requirements when determining the appropriate flow rate for your high flow filter cartridge.

Compatibility with existing filtration systems is also a crucial consideration when selecting a high flow filter cartridge. It is essential to ensure that the high flow filter cartridge is compatible with your existing filtration system to avoid any compatibility issues or performance issues. Consider factors such as size, connection type, and installation requirements when choosing a high flow filter cartridge that seamlessly integrates with your existing filtration system.

In addition to these factors, it is important to consider the material construction of the high flow filter cartridge. High flow filter cartridges are available in a variety of materials, including polypropylene, polyester, and stainless steel. The material construction of the high flow filter cartridge can impact its durability, chemical resistance, and compatibility with different liquids or gases. Consider factors such as temperature resistance, chemical compatibility, and longevity when selecting a high flow filter cartridge with the appropriate material construction for your industry.

When selecting a high flow filter cartridge for your industry, it is essential to consider all of these factors to ensure optimal performance and efficiency. By carefully evaluating the type of contaminants present, flow rate requirements, compatibility with existing filtration systems, and material construction, you can choose the right high flow filter cartridge that meets the specific needs of your industry. Investing in the right high flow filter cartridge can help improve filtration efficiency, reduce maintenance costs, and ensure the quality and purity of your liquids or gases.

Comparison of Different Types of High Flow Filter Cartridges

High flow filter cartridges are essential components in various industries, including pharmaceutical, food and beverage, chemical, and water treatment. These cartridges are designed to remove contaminants and impurities from liquids, ensuring product quality and process efficiency. When it comes to choosing the right high flow filter cartridge for your industry, there are several factors to consider, including the type of contaminants present, flow rate requirements, and compatibility with existing filtration systems.

One of the most common types of high flow filter cartridges is the pleated filter cartridge. Pleated filter cartridges are made from a variety of materials, including polypropylene, polyester, and cellulose. These cartridges have a large surface area, which allows for high flow rates and efficient particle removal. Pleated filter cartridges are ideal for applications where high dirt-holding capacity and long service life are required.

Another type of high flow filter cartridge is the depth filter cartridge. Depth filter cartridges are made from materials such as cellulose, glass fiber, or polypropylene. These cartridges have a dense structure that traps contaminants throughout the depth of the filter media. Depth filter cartridges are effective at removing fine particles and are suitable for applications where high efficiency filtration is necessary.

Membrane filter cartridges are a third type of high flow filter cartridge. Membrane filter cartridges are made from materials such as polyethersulfone (PES), polypropylene, or nylon. These cartridges have a microporous membrane that traps particles larger than the membrane pore size. Membrane filter cartridges are ideal for applications where absolute particle removal is required, such as in the pharmaceutical and biotechnology industries.

When comparing different types of high flow filter cartridges, it is important to consider the filtration efficiency, flow rate, and compatibility with the liquid being filtered. Pleated filter cartridges are known for their high flow rates and dirt-holding capacity, making them suitable for applications with high particle loads. Depth filter cartridges are effective at removing fine particles and are ideal for applications where high efficiency filtration is necessary. Membrane filter cartridges provide absolute particle removal and are suitable for critical applications where product quality is paramount.

In addition to the type of filter cartridge, it is important to consider the micron rating and pore size of the filter media. The micron rating indicates the size of particles that the filter cartridge can remove, with lower micron ratings indicating finer filtration. The pore size of the filter media determines the size of particles that can pass through the filter, with smaller pore sizes providing better particle retention.

When choosing a high flow filter cartridge for your industry, it is essential to consider the specific requirements of your application. Whether you need high flow rates, fine particle removal, or absolute filtration, there is a high flow filter cartridge available to meet your needs. By comparing the different types of high flow filter cartridges and considering factors such as filtration efficiency, flow rate, and compatibility, you can select the right filter cartridge for your industry and ensure optimal performance and product quality.

Case Studies of Successful Implementation of High Flow Filter Cartridges in Various Industries

High flow filter cartridges are an essential component in many industries, helping to remove contaminants and impurities from liquids and gases. Choosing the right high flow filter cartridge for your industry is crucial to ensure optimal performance and efficiency. In this article, we will explore some case studies of successful implementation of high flow filter cartridges in various industries, highlighting the benefits and key considerations to keep in mind when selecting the right filter for your specific needs.

One industry that has seen significant success with high flow filter cartridges is the food and beverage industry. With strict regulations and standards for cleanliness and purity, it is essential for food and beverage manufacturers to have reliable filtration systems in place. By using high flow filter cartridges, these companies have been able to effectively remove contaminants such as bacteria, particles, and other impurities from their products, ensuring that they meet the highest quality standards.

Another industry that has benefited from the use of high flow filter cartridges is the pharmaceutical industry. With a focus on producing safe and effective medications, pharmaceutical companies rely on high-quality filtration systems to ensure the purity of their products. High flow filter cartridges have proven to be an effective solution for removing contaminants and ensuring the quality of pharmaceutical products, helping these companies meet regulatory requirements and maintain their reputation for excellence.

In the oil and gas industry, high flow filter cartridges play a critical role in ensuring the efficiency and reliability of equipment and processes. By using high flow filters, oil and gas companies can remove contaminants such as dirt, sand, and other particles from their fluids, preventing damage to equipment and ensuring smooth operation. With the right high flow filter cartridge in place, these companies can improve the performance of their operations and reduce maintenance costs, ultimately leading to increased productivity and profitability.

The automotive industry is another sector that has seen success with the implementation of high flow filter cartridges. With a focus on producing high-quality vehicles, automotive manufacturers rely on filtration systems to ensure the cleanliness of fluids used in their production processes. High flow filter cartridges have proven to be an effective solution for removing contaminants and ensuring the quality of automotive fluids, helping these companies maintain the performance and reliability of their vehicles.

In conclusion, choosing the right high flow filter cartridge for your industry is essential to ensure optimal performance and efficiency. By considering the specific needs and requirements of your industry, you can select a filter that will effectively remove contaminants and impurities, helping you meet regulatory standards and maintain the quality of your products. The case studies highlighted in this article demonstrate the success that various industries have seen with the implementation of high flow filter cartridges, showcasing the benefits and advantages of using these filters in different applications. Whether you work in the food and beverage, pharmaceutical, oil and gas, automotive, or any other industry, high flow filter cartridges can help you improve the quality and reliability of your products and processes, ultimately leading to increased success and profitability.