Choosing the Right Rosin Press Bag: Tips for Maximum Yield and Quality

Bag Material: Understanding Different Fabrics

When it comes to selecting the right rosin press bag, understanding the various bag materials available is crucial for maximizing both yield and quality. The fabric of the bag plays a significant role in the extraction process, influencing not only the efficiency of the yield but also the purity of the final product. Therefore, it is essential to familiarize oneself with the different types of materials used in rosin press bags to make an informed decision.

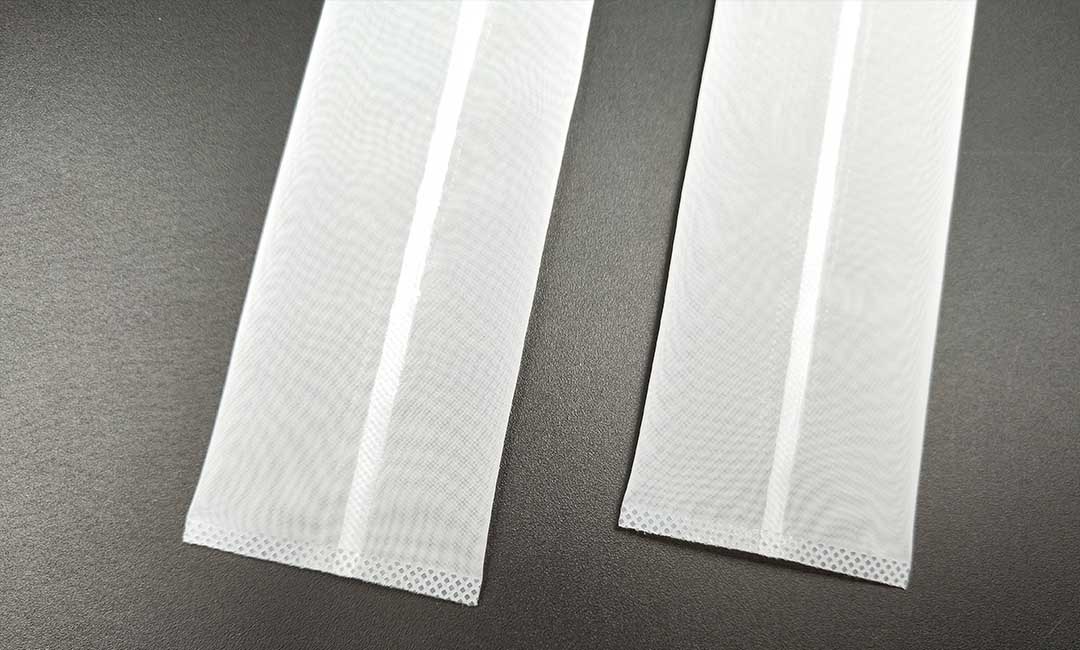

One of the most common materials used in rosin press bags is nylon. Renowned for its durability and resistance to heat, nylon bags can withstand the high temperatures typically employed during the extraction process. This characteristic is particularly important, as it ensures that the bag does not degrade or release unwanted contaminants into the rosin. Additionally, nylon bags are often designed with a tight weave, which helps to filter out unwanted plant material while allowing the essential oils to pass through. Consequently, using nylon bags can lead to a cleaner and more potent final product.

Another popular option is polypropylene, a synthetic fabric that is lightweight yet robust. Polypropylene bags are known for their excellent filtration capabilities, making them suitable for those seeking a high-quality extraction. The material’s resistance to chemicals and moisture further enhances its appeal, as it minimizes the risk of contamination during the extraction process. Moreover, polypropylene bags are often available in various micron sizes, allowing users to select the appropriate filtration level based on their specific needs. This versatility makes polypropylene a favored choice among both novice and experienced extractors.

In contrast, cotton bags offer a more traditional approach to rosin extraction. While they may not possess the same level of heat resistance as nylon or polypropylene, cotton bags are biodegradable and environmentally friendly. This aspect appeals to those who prioritize sustainability in their extraction practices. However, it is essential to note that cotton bags may require more careful handling to prevent degradation under high temperatures. Therefore, users must be mindful of the temperature settings on their rosin press when utilizing cotton bags to ensure optimal results.

Furthermore, some manufacturers have begun to produce hybrid bags that combine different materials to enhance performance. These hybrid bags often feature a nylon exterior for durability and a polypropylene interior for superior filtration. By leveraging the strengths of multiple materials, hybrid bags can provide an excellent balance between yield and quality. This innovation reflects the ongoing evolution in rosin extraction technology, as producers continually seek to improve the efficiency and effectiveness of their processes.

In addition to the material itself, the micron size of the bag is another critical factor to consider. Micron sizes typically range from 25 to 160 microns, with smaller sizes providing finer filtration. While smaller micron bags can yield a purer product, they may also result in lower overall yields due to increased resistance to oil flow. Conversely, larger micron bags may allow for higher yields but could compromise the quality of the final product. Therefore, it is essential to strike a balance between micron size and material choice to achieve the desired outcome.

In conclusion, understanding the various bag materials available for rosin extraction is vital for anyone looking to optimize their yield and quality. By considering factors such as durability, filtration capabilities, and environmental impact, users can make informed decisions that align with their specific extraction goals. Ultimately, the right choice of bag material can significantly enhance the overall rosin extraction experience, leading to superior results.

Size Matters: Selecting the Right Dimensions

When it comes to maximizing yield and quality in the rosin extraction process, selecting the right rosin press bag is crucial, and one of the most significant factors to consider is size. The dimensions of the bag directly influence the efficiency of the extraction, as well as the quality of the final product. Therefore, understanding how to choose the appropriate size is essential for both novice and experienced users alike.

To begin with, it is important to recognize that rosin press bags come in various sizes, typically measured in inches. The size you choose should correspond to the amount of material you intend to process. For instance, if you are working with small quantities, such as a few grams of flower or hash, a smaller bag, perhaps around 2.5 inches by 4 inches, may suffice. Conversely, if you are dealing with larger amounts, such as an ounce or more, opting for a larger bag, like 4 inches by 6 inches or even larger, will be necessary to accommodate the volume of material without compromising the extraction process.

Moreover, the size of the bag also affects the pressure distribution during extraction. A bag that is too small for the amount of material can lead to uneven pressure, resulting in suboptimal yields and potentially lower quality rosin. When the material is packed too tightly, it can restrict the flow of oils and terpenes, which are essential for achieving a high-quality product. Therefore, it is advisable to select a bag that allows for adequate space for the material to expand and release its oils effectively.

In addition to considering the amount of material, the type of material being processed also plays a significant role in determining the appropriate bag size. For example, if you are working with dry sift or kief, which is more finely ground, a smaller bag may be suitable. However, when using whole flower, which has a larger structure and requires more space to release its oils, a larger bag is recommended. This distinction is vital, as using the wrong size can lead to a compromised extraction process, resulting in lower yields and diminished quality.

Furthermore, it is essential to consider the type of rosin press being used. Different presses may have varying plate sizes and pressure capabilities, which can influence the choice of bag size. Ensuring that the bag fits well within the press is crucial for achieving optimal results. A bag that is too large may not fit properly, leading to inefficient extraction, while a bag that is too small may not withstand the pressure applied during the process.

Ultimately, selecting the right dimensions for your rosin press bag is a critical step in the extraction process. By carefully considering the amount and type of material, as well as the specifications of your rosin press, you can ensure that you are using a bag that maximizes both yield and quality. In conclusion, taking the time to choose the appropriate size will not only enhance your extraction experience but also contribute to producing a superior final product that meets your expectations. Thus, size truly matters when it comes to achieving the best results in rosin extraction.

Micron Ratings: How to Choose the Best Filter

When it comes to maximizing yield and quality in the extraction process, selecting the right rosin press bag is crucial, and understanding micron ratings is a fundamental aspect of this decision. Micron ratings refer to the size of the filter’s pores, which directly influences the efficiency of the extraction process. The choice of micron size can significantly affect both the quantity and quality of the rosin produced, making it essential to comprehend how these ratings work.

Typically, rosin press bags come in a range of micron sizes, often from 25 to 160 microns. A lower micron rating, such as 25 or 37 microns, is ideal for extracting finer particles, which can lead to a purer and more potent product. These smaller bags are particularly effective for high-quality flower or hash, as they allow the essential oils and cannabinoids to pass through while filtering out unwanted plant material. However, while lower micron bags can yield a cleaner product, they may also be more prone to clogging, especially when working with larger quantities or denser materials.

Conversely, higher micron ratings, such as 90 or 160 microns, are better suited for coarser materials or when working with larger quantities. These bags allow for a quicker extraction process, as they are less likely to clog. However, the trade-off is that they may allow more plant material to pass through, potentially compromising the purity and flavor of the final product. Therefore, when choosing a rosin press bag, it is essential to consider the type of material being processed and the desired outcome.

In addition to the micron size, the material and construction of the rosin press bag also play a significant role in the extraction process. High-quality bags are typically made from durable, heat-resistant materials that can withstand the pressures and temperatures involved in rosin extraction. It is advisable to select bags that are stitched rather than glued, as stitched seams tend to be more robust and less likely to rupture under pressure. This durability ensures that the bag maintains its integrity throughout the extraction process, allowing for a more efficient yield.

Moreover, it is important to consider the specific strain or type of material being used. Different strains may have varying levels of moisture and oil content, which can influence the choice of micron size. For instance, a strain with a high oil content may benefit from a lower micron bag to capture the maximum amount of essential oils, while a drier strain may perform better with a higher micron bag to facilitate smoother extraction. Therefore, experimenting with different micron sizes can be beneficial in determining the optimal setup for each specific material.

Ultimately, the key to achieving maximum yield and quality lies in understanding the relationship between micron ratings and the characteristics of the material being processed. By carefully selecting the appropriate micron size and ensuring the use of high-quality bags, extractors can enhance both the efficiency of their extraction process and the quality of the rosin produced. This thoughtful approach not only leads to better yields but also contributes to a more refined and enjoyable end product, making the investment in the right rosin press bag a worthwhile endeavor for any serious extractor.

Pre-Press Techniques: Maximizing Your Rosin Extraction

When it comes to maximizing yield and quality in rosin extraction, pre-press techniques play a crucial role. The process of preparing your material before it undergoes the pressing phase can significantly influence the final product’s potency and purity. To begin with, it is essential to understand the importance of the starting material. High-quality flower or hash is fundamental, as the characteristics of the input directly affect the output. Therefore, selecting the right strain with a high resin content is the first step in ensuring a successful extraction.

Once you have chosen your material, the next step involves proper curing and drying. Curing allows the plant to develop its full flavor profile and potency, while drying ensures that excess moisture is removed. Moisture content can lead to undesirable results during pressing, such as the formation of unwanted contaminants or a lower yield. Ideally, the material should be dried to a moisture content of around 10-12%. This balance is critical, as overly dry material can lead to a loss of terpenes, while overly moist material can hinder the extraction process.

After ensuring that your material is adequately dried and cured, the next phase involves grinding. The grind size is a pivotal factor in the extraction process. A finer grind increases the surface area, allowing for more efficient extraction of the resin. However, it is essential to avoid grinding the material too finely, as this can lead to the inclusion of plant matter in the final product, which may compromise its quality. A medium grind is often recommended, as it strikes a balance between maximizing surface area and maintaining the integrity of the material.

Following grinding, the pre-pressing stage is where the magic begins. Pre-pressing involves compacting the material into a uniform shape, which can enhance the efficiency of the extraction process. This step is particularly beneficial when using rosin press bags, as it helps to create a consistent puck that can be easily handled and pressed. When pre-pressing, it is advisable to use a hydraulic press or a manual pre-press mold to achieve the desired density. The goal is to create a compact puck that allows for even distribution of heat and pressure during the pressing phase.

Moreover, the choice of rosin press bag is integral to the pre-press technique. Selecting the right micron size is essential, as it determines the filtration of the extracted oil. A bag with a micron size that is too large may allow unwanted plant material to pass through, while a bag that is too small can restrict the flow of oil, leading to lower yields. Generally, bags with a micron size between 25 and 160 are recommended, depending on the type of material being used. For flower, a 90 to 120 micron bag is often ideal, while hash may benefit from a smaller micron size.

In addition to these techniques, maintaining a consistent temperature during the pressing process is vital. The ideal temperature range for rosin extraction typically falls between 180°F and 220°F. Staying within this range helps to preserve the terpenes and cannabinoids, ensuring that the final product is both potent and flavorful. By implementing these pre-press techniques, including careful selection of material, proper curing, grinding, and the use of appropriate rosin press bags, you can significantly enhance your rosin extraction process. Ultimately, these steps will lead to a higher yield and superior quality, allowing you to enjoy the full benefits of your extraction efforts.