Comparing Polyester Spiral Belt Suppliers: What to Look For

Quality of Materials Used

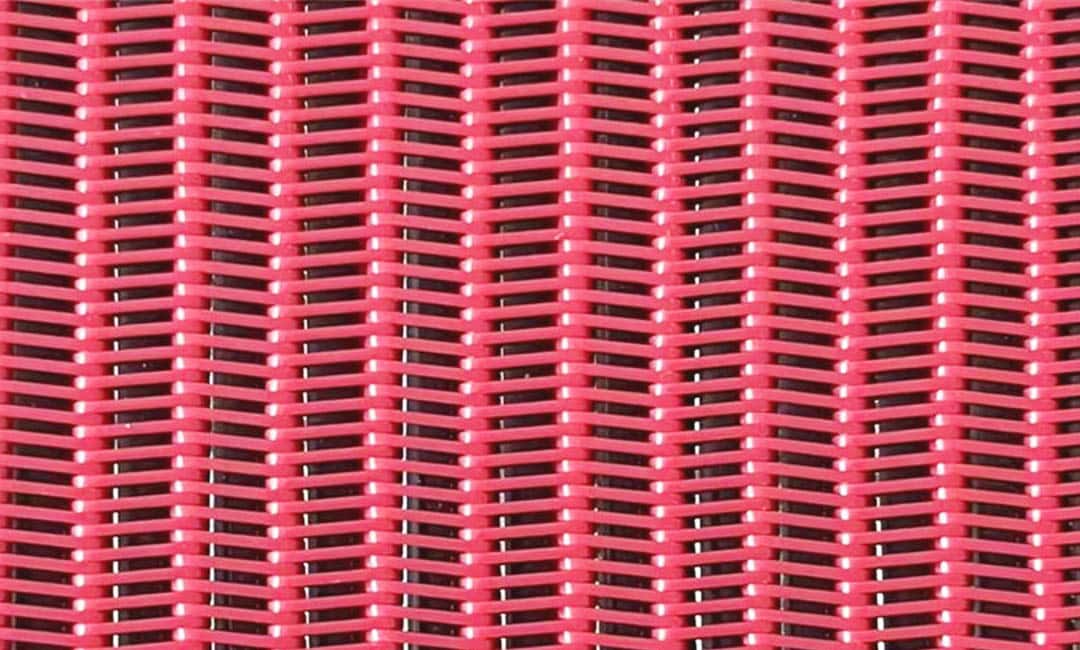

When considering polyester spiral belt suppliers, one of the most critical factors to evaluate is the quality of materials used in their products. The quality of materials directly influences the performance, durability, and overall effectiveness of the belts in various applications. Polyester, known for its strength and resistance to wear, is a popular choice in the manufacturing of spiral belts. However, not all polyester is created equal, and the specific grade and treatment of the polyester can significantly impact the belt’s functionality.

To begin with, it is essential to understand the different grades of polyester available in the market. High-quality polyester typically exhibits superior tensile strength, which is crucial for applications that require the belt to withstand heavy loads and continuous use. Suppliers that utilize industrial-grade polyester often provide products that can endure harsh conditions, including extreme temperatures and exposure to chemicals. Therefore, when comparing suppliers, it is advisable to inquire about the specific grade of polyester they use and whether it meets industry standards.

In addition to the grade of polyester, the manufacturing process plays a vital role in determining the quality of the final product. Suppliers that employ advanced manufacturing techniques, such as precision weaving and heat setting, are more likely to produce belts that offer enhanced stability and reduced elongation over time. This stability is particularly important in applications where consistent tension is required to maintain operational efficiency. Furthermore, a well-constructed polyester spiral belt will exhibit minimal shrinkage and deformation, ensuring that it performs reliably throughout its lifespan.

Another aspect to consider is the supplier’s commitment to quality control. Reputable suppliers often implement rigorous testing protocols to ensure that their products meet specific performance criteria. This may include testing for tensile strength, abrasion resistance, and overall durability. By choosing a supplier that prioritizes quality control, customers can have greater confidence in the reliability of the belts they purchase. It is beneficial to ask potential suppliers about their quality assurance processes and whether they have certifications that validate their commitment to producing high-quality materials.

Moreover, the environmental impact of the materials used is becoming increasingly important in today’s market. Suppliers that source their polyester from recycled materials or utilize sustainable manufacturing practices are not only contributing to environmental conservation but also appealing to a growing segment of eco-conscious consumers. When comparing suppliers, it is worthwhile to consider their sustainability initiatives and how they align with your own values and business practices.

In addition to the material quality, the supplier’s reputation and experience in the industry can provide valuable insights into the reliability of their products. Established suppliers with a proven track record are more likely to have the expertise necessary to produce high-quality polyester spiral belts. Customer reviews and testimonials can also serve as a useful resource when evaluating potential suppliers, as they offer firsthand accounts of product performance and customer service.

Ultimately, the quality of materials used in polyester spiral belts is a crucial factor that can significantly affect their performance and longevity. By carefully assessing the grade of polyester, the manufacturing processes employed, the supplier’s quality control measures, and their commitment to sustainability, businesses can make informed decisions when selecting a supplier. This thorough evaluation not only ensures that the belts will meet operational demands but also contributes to the overall success and efficiency of the applications in which they are utilized.

Supplier Reputation and Experience

When it comes to choosing a supplier for polyester spiral belts, there are several factors to consider. One of the most important aspects to look at is the supplier’s reputation and experience in the industry. A supplier with a good reputation and years of experience is more likely to provide high-quality products and excellent customer service.

One way to gauge a supplier’s reputation is to look at their customer reviews and testimonials. This can give you an idea of how satisfied their customers are with the products and services they provide. Positive reviews and feedback are a good indication that the supplier is reliable and trustworthy. On the other hand, negative reviews or complaints may be a red flag that the supplier does not deliver on their promises.

In addition to customer reviews, you can also research the supplier’s experience in the industry. A supplier that has been in business for many years is likely to have a good understanding of the market and the needs of their customers. They may also have developed strong relationships with manufacturers and other suppliers, which can be beneficial for you as a buyer.

Another important factor to consider when comparing polyester spiral belt suppliers is their track record of delivering orders on time. A supplier that consistently meets deadlines and delivers products as promised is more likely to be reliable and trustworthy. On the other hand, a supplier that frequently misses deadlines or delivers products late may not be the best choice for your business.

It is also important to consider the supplier’s communication and customer service. A supplier that is responsive to your inquiries and provides clear and timely communication is more likely to be easy to work with. Good customer service can make a big difference when it comes to resolving any issues or concerns that may arise during the ordering process.

When comparing suppliers, it is also important to consider their pricing and payment terms. While cost is certainly an important factor, it should not be the only consideration when choosing a supplier. It is important to weigh the cost of the products against the quality and reliability of the supplier. In addition, you should also consider the supplier’s payment terms and whether they are flexible and accommodating to your needs.

In conclusion, when comparing polyester spiral belt suppliers, it is important to consider their reputation, experience, track record, communication, customer service, pricing, and payment terms. By carefully evaluating these factors, you can choose a supplier that meets your needs and provides high-quality products and excellent service. Remember to do your research, ask questions, and make an informed decision based on the information available to you.

Customization Options and Flexibility

When evaluating polyester spiral belt suppliers, one of the most critical aspects to consider is the range of customization options and the flexibility they offer. Customization is essential in ensuring that the belts meet specific operational requirements, which can vary significantly across different industries. A supplier that provides a variety of customization options can cater to unique needs, enhancing the efficiency and effectiveness of the production process. This flexibility can manifest in several ways, including the ability to modify dimensions, materials, and design features of the belts.

One of the primary factors to assess is the supplier’s capability to produce belts in various sizes and configurations. Different applications may require belts of specific widths, lengths, or thicknesses. A supplier that can accommodate these variations demonstrates a commitment to meeting customer needs. Furthermore, the ability to produce belts with varying pitch sizes and spiral configurations can significantly impact the performance of the belt in its intended application. For instance, tighter pitches may be necessary for applications requiring more precise handling of products, while wider pitches might be suitable for bulk material handling.

In addition to size and configuration, the choice of materials is another critical aspect of customization. Polyester spiral belts can be manufactured from different grades of polyester, each offering distinct properties such as strength, durability, and resistance to chemicals or temperature extremes. A supplier that provides options for material selection allows businesses to choose the most suitable belt for their specific operational environment. This is particularly important in industries such as food processing, where hygiene and safety standards are paramount. Suppliers that offer belts with FDA-approved materials or those that are easy to clean can provide significant advantages in maintaining compliance with industry regulations.

Moreover, the design features of the belts can also be customized to enhance functionality. For example, some applications may benefit from belts with special surface textures or coatings that improve grip or reduce friction. Suppliers that offer these design modifications can help businesses optimize their processes, leading to increased productivity and reduced downtime. Additionally, the ability to incorporate features such as sidewalls or cleats can further enhance the versatility of the belts, allowing them to handle a wider range of products and materials.

Another important consideration is the supplier’s willingness to collaborate with customers during the design and customization process. A supplier that engages in open communication and actively seeks input from clients can better understand their specific needs and challenges. This collaborative approach not only fosters a stronger partnership but also ensures that the final product aligns closely with the customer’s expectations. Furthermore, suppliers that offer prototyping services can provide valuable insights into the performance of customized belts before full-scale production, allowing for adjustments and refinements as needed.

Finally, it is essential to evaluate the lead times and production capabilities of potential suppliers. A supplier that can quickly adapt to changing demands and deliver customized belts in a timely manner can significantly impact a business’s operational efficiency. In industries where downtime can lead to substantial losses, having a reliable supplier that can respond swiftly to customization requests is invaluable.

In conclusion, when comparing polyester spiral belt suppliers, the emphasis on customization options and flexibility is paramount. By considering factors such as size, material selection, design features, collaborative processes, and production capabilities, businesses can make informed decisions that enhance their operational efficiency and effectiveness. Ultimately, a supplier that prioritizes customization and flexibility will be better positioned to meet the evolving needs of its clients, fostering long-term partnerships and success.