Comprehensive Guide to Rosin Press Bag Options for All Extraction Needs

Benefits of Using Rosin Press Bags

The use of rosin press bags has become increasingly popular among those engaged in the extraction of essential oils and concentrates from plant materials. These specialized bags serve a crucial role in the rosin extraction process, offering a range of benefits that enhance both the quality of the final product and the efficiency of the extraction process itself. One of the primary advantages of using rosin press bags is their ability to filter out unwanted plant material, such as stems and leaves, while allowing the desired resin to pass through. This filtration process is essential for producing a clean and pure concentrate, which is particularly important for consumers who prioritize quality and potency in their products.

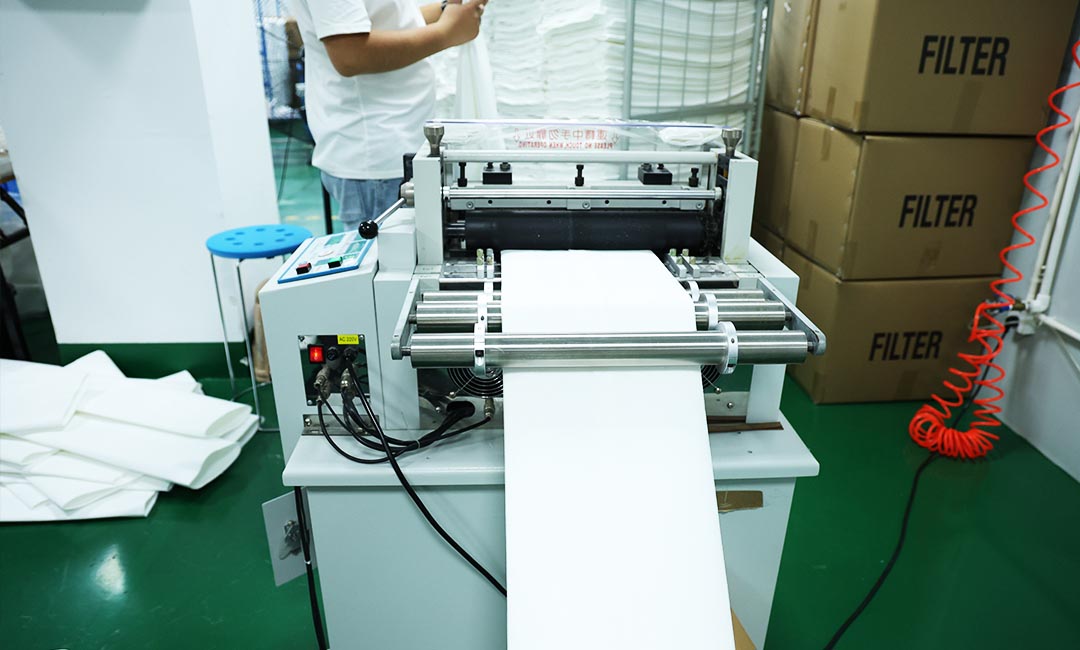

Moreover, rosin press bags are designed to withstand the high pressures and temperatures involved in the extraction process. This durability ensures that the bags do not tear or degrade during pressing, which could otherwise lead to contamination of the final product. By using high-quality materials, these bags maintain their integrity, allowing for a more efficient extraction process. As a result, users can achieve higher yields of rosin, maximizing the return on their investment in both time and resources.

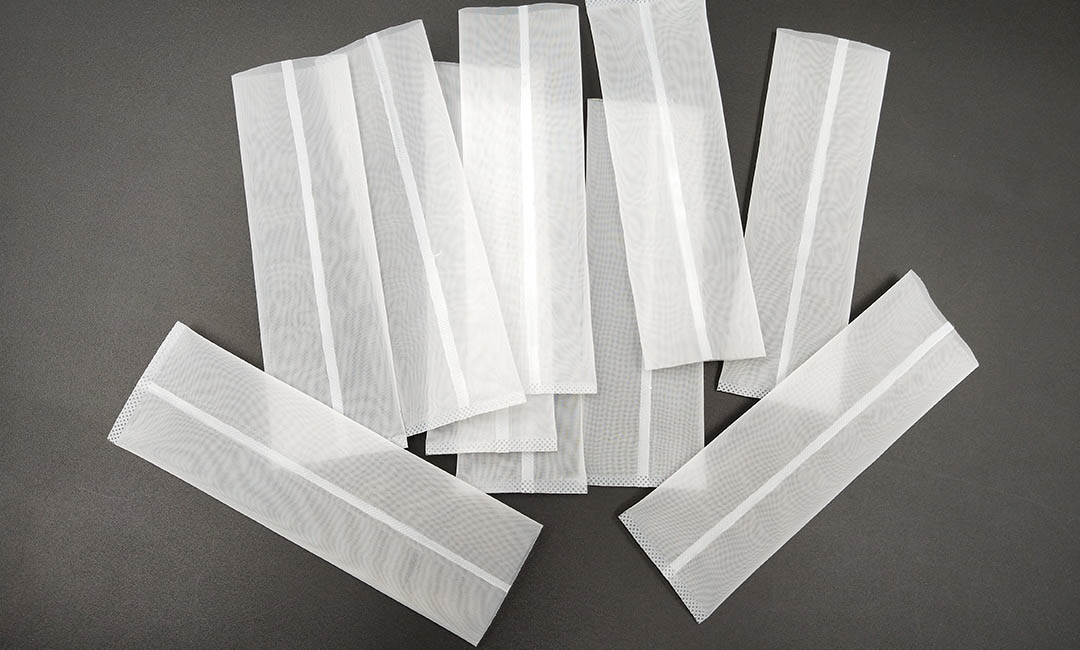

In addition to their filtering capabilities and durability, rosin press bags come in various sizes and micron ratings, catering to a wide range of extraction needs. The micron rating refers to the size of the mesh openings in the bag, which determines the size of the particles that can pass through. For instance, bags with lower micron ratings are ideal for extracting finer particles, resulting in a more refined product. Conversely, higher micron bags are suitable for coarser materials, allowing for a broader range of extraction options. This versatility enables users to select the appropriate bag for their specific material and desired outcome, further enhancing the overall efficiency of the extraction process.

Another significant benefit of using rosin press bags is their ease of use. The design of these bags allows for straightforward loading and unloading of plant material, streamlining the extraction process. Users can quickly fill the bags with their chosen material, seal them securely, and place them in the press without the need for complicated setups or additional equipment. This simplicity not only saves time but also reduces the likelihood of errors during the extraction process, leading to more consistent results.

Furthermore, rosin press bags contribute to a cleaner extraction environment. By containing the plant material and resin during the pressing process, these bags minimize mess and reduce the risk of cross-contamination. This cleanliness is particularly important for those who operate in professional settings, where maintaining a sterile environment is crucial for compliance with health and safety regulations. Additionally, the use of rosin press bags can facilitate easier cleanup after the extraction process, allowing users to focus on refining their techniques rather than dealing with the aftermath of a messy operation.

In conclusion, the benefits of using rosin press bags are manifold, encompassing improved product quality, enhanced extraction efficiency, and ease of use. Their ability to filter out unwanted materials, withstand high pressures, and come in various sizes and micron ratings makes them an indispensable tool for anyone involved in the rosin extraction process. As the demand for high-quality concentrates continues to grow, the role of rosin press bags in achieving optimal results cannot be overstated. By investing in the right bags, users can elevate their extraction practices, ensuring that they produce the finest rosin possible.

Different Types of Rosin Press Bags

When it comes to rosin extraction, the choice of rosin press bags is crucial for achieving optimal results. These bags serve as a filter during the extraction process, allowing the desired resin to pass through while retaining unwanted plant material. Understanding the different types of rosin press bags available can significantly enhance the quality of the final product, making it essential for both novice and experienced extractors to familiarize themselves with their options.

One of the most common types of rosin press bags is the standard nylon bag, which is favored for its durability and effectiveness. These bags are typically available in various micron sizes, which refer to the size of the holes in the fabric. Smaller micron sizes, such as 25 to 90 microns, are ideal for finer materials, as they allow for the extraction of high-quality rosin while filtering out most of the plant matter. Conversely, larger micron sizes, such as 160 to 220 microns, are better suited for coarser materials, enabling a quicker extraction process while still yielding a satisfactory product. The choice of micron size ultimately depends on the specific material being processed and the desired outcome.

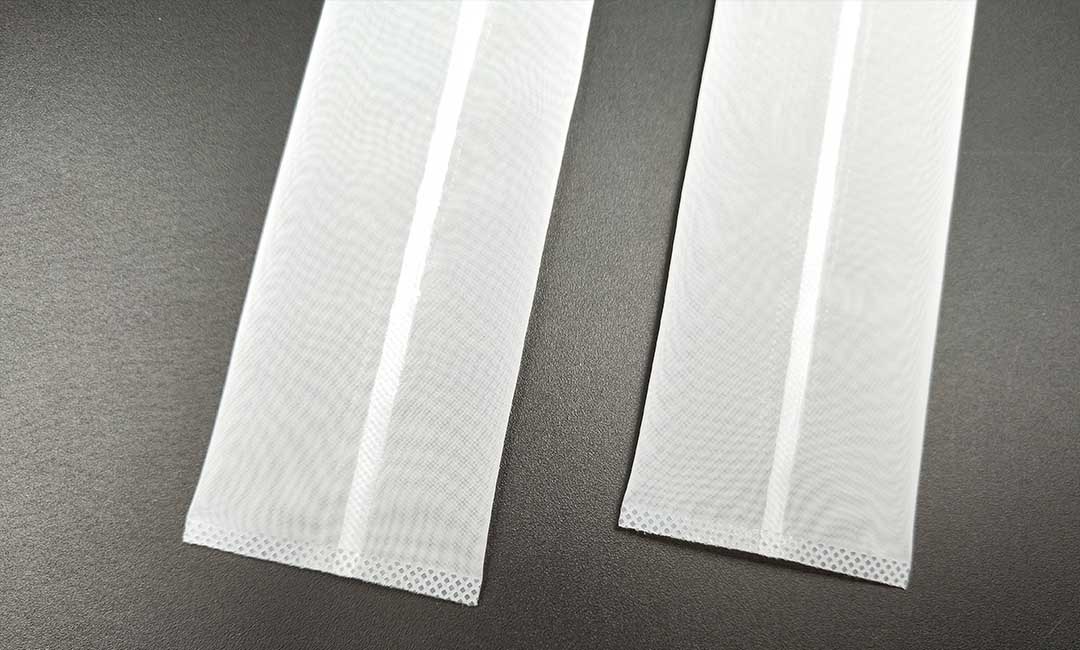

In addition to standard nylon bags, there are also specialized rosin press bags designed for specific extraction needs. For instance, some bags are constructed with a double-layer design, which provides an extra level of filtration. This feature is particularly beneficial when working with materials that contain a higher concentration of plant matter, as it helps to ensure a cleaner final product. Furthermore, these double-layer bags can enhance the overall yield by allowing more resin to be extracted without compromising quality.

Another option worth considering is the use of mesh bags, which are often made from polyester or other synthetic materials. These bags are designed to provide a different filtration experience, as the mesh allows for greater airflow during the extraction process. This increased airflow can lead to a more efficient extraction, as it helps to prevent the material from becoming overly saturated. Additionally, mesh bags are typically easier to clean and reuse, making them a cost-effective choice for those who engage in frequent extraction sessions.

For those seeking a more eco-friendly option, biodegradable rosin press bags are becoming increasingly popular. These bags are made from natural materials that break down over time, reducing environmental impact. While they may not offer the same level of durability as their synthetic counterparts, they can still provide satisfactory results for those who prioritize sustainability in their extraction practices. It is important to note, however, that the performance of biodegradable bags may vary depending on the specific extraction conditions.

Moreover, some manufacturers offer custom-sized rosin press bags, allowing extractors to tailor their equipment to their specific needs. This customization can be particularly advantageous for those working with unique materials or in specialized extraction setups. By selecting the appropriate size and micron rating, extractors can optimize their process and achieve the best possible results.

In conclusion, the variety of rosin press bags available on the market caters to a wide range of extraction needs. From standard nylon bags to specialized double-layer and mesh options, each type offers distinct advantages that can enhance the extraction process. Additionally, the emergence of biodegradable bags provides an eco-friendly alternative for conscientious extractors. By understanding the different types of rosin press bags and their respective benefits, individuals can make informed decisions that will ultimately lead to higher-quality rosin and a more efficient extraction experience.

How to Choose the Right Rosin Press Bag for Your Extraction Needs

When it comes to extracting rosin, the choice of press bag is a critical factor that can significantly influence the quality and yield of the final product. Selecting the right rosin press bag involves understanding various aspects, including material, micron size, and bag dimensions, all of which play a vital role in the extraction process. To begin with, the material of the press bag is paramount. Most rosin press bags are made from nylon or polyester, both of which offer durability and resistance to heat. Nylon bags are often preferred for their ability to withstand higher temperatures, making them suitable for a range of extraction methods. Conversely, polyester bags may be more cost-effective and still provide adequate performance for lower-temperature extractions.

In addition to material, the micron size of the bag is another crucial consideration. Micron size refers to the size of the holes in the bag, which directly affects the filtration process. A smaller micron size, typically ranging from 25 to 160 microns, is ideal for finer materials, as it allows for the extraction of high-quality rosin while preventing unwanted plant material from contaminating the final product. On the other hand, larger micron sizes may be more appropriate for coarser materials, as they facilitate a quicker extraction process while still yielding a satisfactory product. Therefore, understanding the type of material being processed is essential in determining the appropriate micron size for the rosin press bag.

Furthermore, the dimensions of the press bag should align with the scale of the extraction operation. For home users or small-scale operations, smaller bags may suffice, allowing for manageable quantities of material to be processed at once. However, larger commercial operations may require bigger bags to accommodate larger batches, ensuring efficiency and maximizing yield. It is also important to consider the compatibility of the bag with the rosin press being used. Ensuring that the bag fits well within the press will help prevent any issues during the extraction process, such as tearing or leaking, which can compromise the quality of the rosin.

Another factor to consider is the number of bags needed for a particular extraction session. Many users find it beneficial to have a variety of bag sizes and micron options on hand, allowing for flexibility depending on the material being processed. This versatility can enhance the overall extraction experience, enabling users to experiment with different combinations to achieve the desired results. Additionally, some manufacturers offer pre-pressed bags, which can save time and effort during the extraction process, particularly for those who are new to rosin extraction.

Moreover, it is advisable to consider the reputation and reviews of the bag manufacturer. Quality can vary significantly between brands, and investing in well-reviewed products can lead to better extraction outcomes. Engaging with online communities or forums dedicated to rosin extraction can provide valuable insights and recommendations based on real-world experiences.

In conclusion, choosing the right rosin press bag is a multifaceted decision that requires careful consideration of material, micron size, dimensions, and the specific needs of the extraction process. By taking the time to evaluate these factors, users can enhance their rosin extraction experience, ultimately leading to higher quality and more efficient yields. As the rosin extraction landscape continues to evolve, staying informed about the latest options and techniques will further empower users to make the best choices for their extraction needs.

Tips for Maximizing Efficiency and Yield with Rosin Press Bags

Rosin press bags are an essential tool for anyone looking to maximize efficiency and yield when using a rosin press for extraction. These bags come in a variety of sizes, materials, and micron ratings, each serving a specific purpose depending on the type of material being pressed. In this comprehensive guide, we will explore the different options available for rosin press bags and provide tips for selecting the right bag for your extraction needs.

When it comes to selecting the right rosin press bag, one of the most important factors to consider is the material. The two most common materials used for rosin press bags are nylon and polyester. Nylon bags are known for their durability and heat resistance, making them ideal for high-temperature extractions. Polyester bags, on the other hand, are more affordable and offer good heat resistance, but may not be as durable as nylon bags.

In addition to material, the micron rating of a rosin press bag is also crucial in determining the quality of the extraction. The micron rating refers to the size of the pores in the bag, with lower micron ratings indicating smaller pores. Bags with lower micron ratings are ideal for pressing finer materials, such as kief or bubble hash, as they help to filter out impurities and produce a cleaner final product. Higher micron bags are better suited for pressing larger materials, such as flower or trim, as they allow for more airflow and prevent blowouts during the pressing process.

When selecting a rosin press bag, it is important to consider the size of the bag in relation to the amount of material being pressed. Bags that are too small may not be able to accommodate the material, leading to blowouts and a decrease in yield. Conversely, bags that are too large may not provide enough pressure to properly extract the material, resulting in a lower-quality final product. It is recommended to use bags that are slightly larger than the amount of material being pressed to ensure a proper fit and maximize yield.

Another important factor to consider when selecting a rosin press bag is the seam construction. Bags with reinforced seams are more durable and less likely to break during the pressing process, resulting in a higher yield and a cleaner final product. It is also important to ensure that the seams are properly aligned to prevent leaks and blowouts.

In addition to selecting the right rosin press bag, there are several tips that can help maximize efficiency and yield during the extraction process. One tip is to pre-press the material before placing it in the bag, as this helps to evenly distribute the material and prevent blowouts. Another tip is to use a pre-press mold to shape the material before placing it in the bag, which can help to increase yield and produce a more consistent final product.

Overall, selecting the right rosin press bag is essential for maximizing efficiency and yield during the extraction process. By considering factors such as material, micron rating, size, and seam construction, you can ensure that you are using the best bag for your extraction needs. Additionally, following tips such as pre-pressing the material and using a pre-press mold can help to further enhance the quality of your extractions. With the right rosin press bag and proper techniques, you can achieve optimal results and produce high-quality rosin every time.