DOE PP Melt blown Filter Cartridge

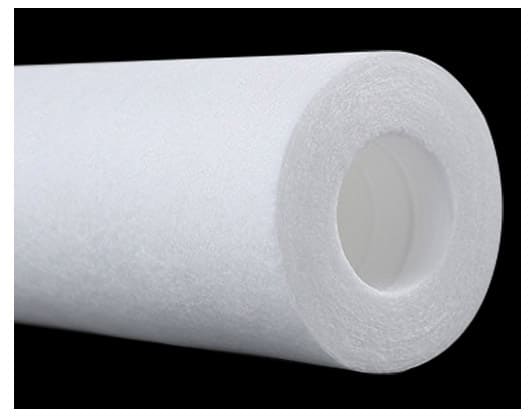

The filter cartridges use absolute precision filter media. All parts are thermally bonded and contain no adhesives or hot glue. These filter elements provide high flow rates and low-pressure drops. In addition, it can be used for repeated sterilization and disinfection operations, with extremely low extractable content and good dirt-holding capacity.

| Product name: | PP melt blown filter cartridge |

| Filter material: | PP polypropylene |

| Filter rating: | 1um, 3um, 5um, 10um, 20um, 30um, 60um |

| Length: | 5″,10″,20″,30″,40″ |

| PH: | 1-13 |

| Pressure difference: | Forward 0.4Mpa. |

| Working temperature: | <70ºC under 0.25 Mpa. |

| Sterilization: | Tolerate 126°C, 30 minutes online steam sterilization. |

| Endotoxin: | The water extract of the filter column is tested by IAL and the endotoxin content is less than 0.5 EU/ml |

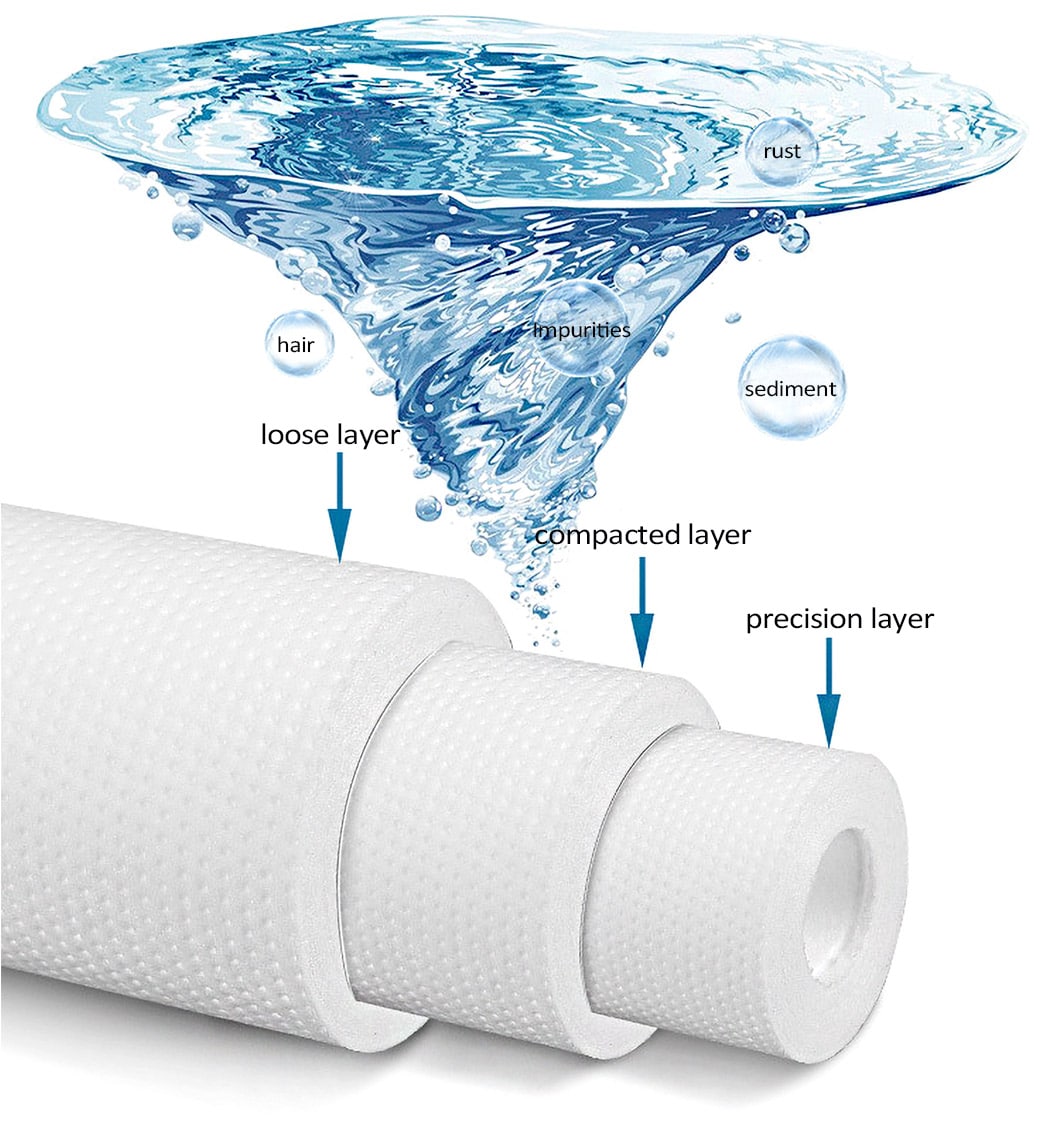

THREE-LAYER FILTER STRUCTURE

The outer layer is loose and the inner layer is tight.

Each layer can give full play to the better filtering effect.

Features:

1. High filtration efficiency, accurate filter rating, uniform filter cartridge pores.

Up to 85% filtration efficiency.

2. Low filtration resistance, high flow, high dirt holding capacity, and long service life.

During the production process, the fiber diameter and gap are adjustable.

The filter cartridge pore is small in the inner layers and large in the outer layers, which enhances its flow

and dirt-holding capacity and makes the filter cartridge not easily clogged, thereby extending

its service life.

3. High cleanness, no pollution to water quality, great resistance to acids, bases, organic solvents, and corrosion.

4. High strength. When the differential pressure between the filter inlet and outlet exceeds 0.4 MPa, the filter cartridge will not deform; when the temperature is greater than 90 °C, the filter efficiency will not be reduced.

5. It has high hydrophilicity after PP treatment and can absorb 10 times the weight of water so that it can be used in oil and water separation applications.

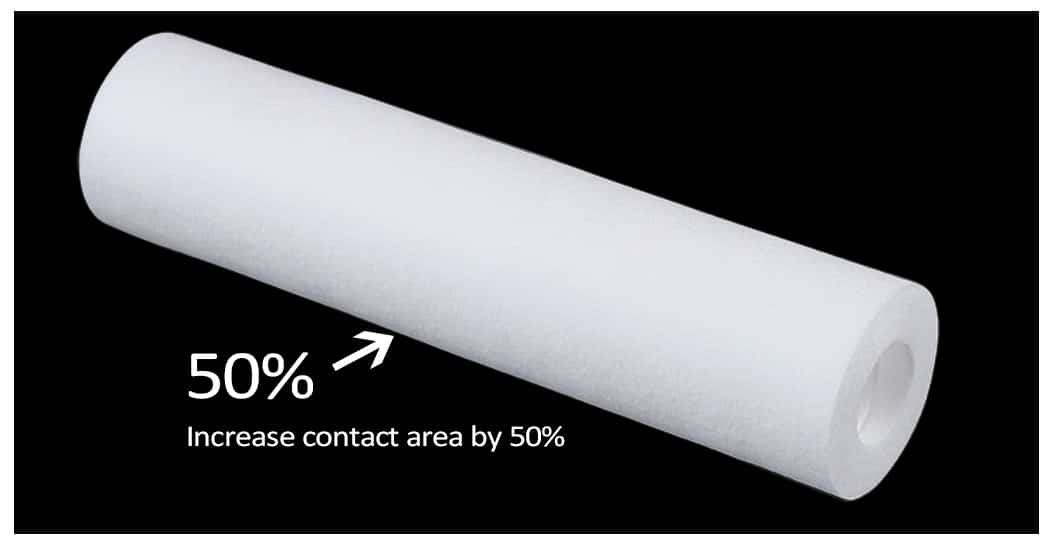

PLANE BRUSHED DESIGN

The plane design allows a larger area to contact the water source, increasing the contact area by more than 50%, resulting in greater flow and stronger dirt-holding capacity.

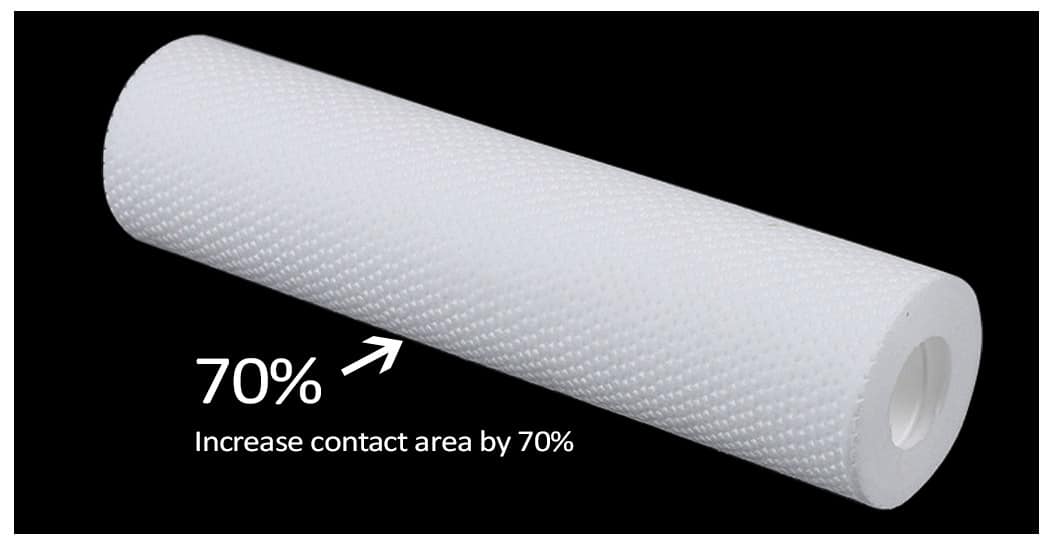

TRENCH PROCESS

The fibers are finer, the structure is tighter, the density is higher, the dirt-holding capacity is stronger, and the purified water flow rate is increased.

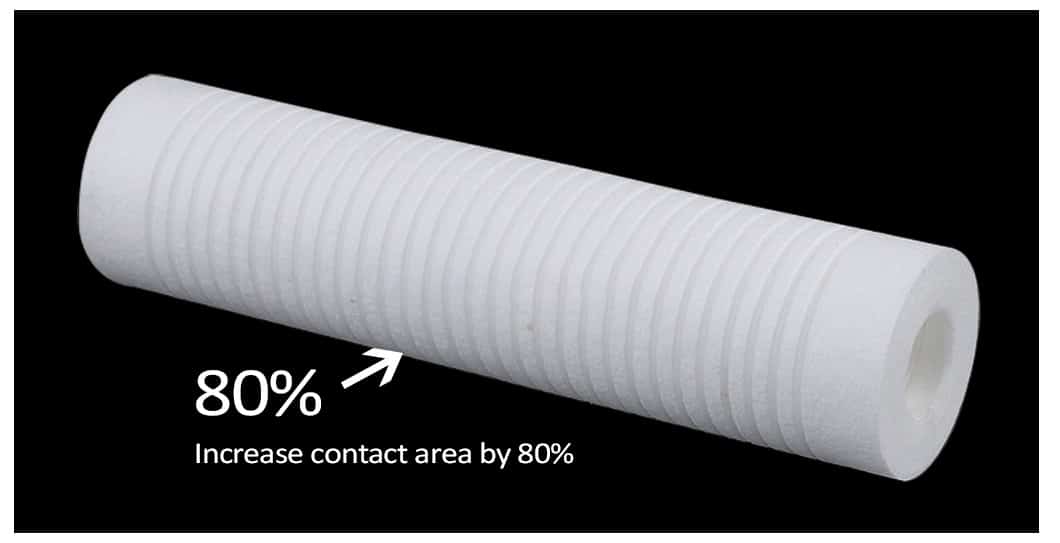

NEEDLE PUNCHED GROOVE DESIGN

The groove design allows a larger area to contact the water source, increasing the contact area by more than 70%, resulting in greater flow and stronger dirt holding capacity.