Enhancing Drying Efficiency with Polyester Fabric Belts

Benefits of Polyester Fabric Belts in Industrial Drying Processes

In the realm of industrial drying processes, the choice of materials plays a pivotal role in determining efficiency and effectiveness. Among the various options available, polyester fabric belts have emerged as a preferred choice for many industries. The benefits of these belts extend beyond mere functionality; they encompass durability, versatility, and cost-effectiveness, making them an invaluable asset in drying applications.

One of the primary advantages of polyester fabric belts is their exceptional strength and durability. Polyester fibers are known for their resistance to wear and tear, which is particularly important in industrial settings where equipment is subjected to continuous use. This durability translates into longer service life for the belts, reducing the frequency of replacements and maintenance. Consequently, industries can experience significant cost savings over time, as the need for frequent repairs or replacements diminishes. Furthermore, the robust nature of polyester fabric allows it to withstand high temperatures and varying humidity levels, ensuring consistent performance even in challenging environments.

In addition to their durability, polyester fabric belts offer remarkable versatility. They can be engineered to meet specific requirements, such as varying thicknesses, widths, and surface textures. This adaptability makes them suitable for a wide range of drying applications, from textiles to food products. For instance, in the textile industry, polyester belts can effectively transport wet fabrics through drying ovens, ensuring uniform drying without causing damage. Similarly, in the food processing sector, these belts can facilitate the drying of fruits and vegetables, maintaining product quality while enhancing throughput. The ability to customize polyester belts for different applications allows industries to optimize their drying processes, leading to improved efficiency and productivity.

Moreover, polyester fabric belts contribute to energy efficiency in drying operations. Their lightweight nature reduces the overall load on drying equipment, which can lead to lower energy consumption. When combined with advanced drying technologies, such as infrared or microwave drying, polyester belts can enhance the overall energy efficiency of the process. This is particularly important in an era where energy costs are rising and sustainability is becoming a priority for many businesses. By utilizing polyester fabric belts, industries can not only reduce their operational costs but also minimize their environmental impact, aligning with global sustainability goals.

Another significant benefit of polyester fabric belts is their ease of maintenance. Unlike some other materials that may require specialized cleaning agents or procedures, polyester belts can typically be cleaned with standard detergents and water. This simplicity in maintenance not only saves time but also ensures that the belts remain in optimal condition, thereby prolonging their lifespan. Additionally, the non-porous nature of polyester fabric helps prevent the absorption of moisture and contaminants, further enhancing hygiene and cleanliness in industrial drying processes.

In conclusion, the integration of polyester fabric belts into industrial drying processes offers a multitude of benefits that can significantly enhance operational efficiency. Their durability ensures longevity and reduced maintenance costs, while their versatility allows for customization to meet specific application needs. Furthermore, the energy efficiency and ease of maintenance associated with polyester belts make them an attractive option for industries seeking to optimize their drying operations. As businesses continue to prioritize efficiency and sustainability, the role of polyester fabric belts in industrial drying processes is likely to become increasingly prominent, paving the way for enhanced productivity and reduced environmental impact.

Techniques for Optimizing Drying Efficiency with Polyester Belts

In the quest for enhanced drying efficiency, the utilization of polyester fabric belts has emerged as a pivotal factor in various industrial applications. Polyester, known for its durability and resistance to moisture, offers a unique combination of properties that can significantly improve the drying process. To optimize drying efficiency with polyester belts, several techniques can be employed, each contributing to a more effective and streamlined operation.

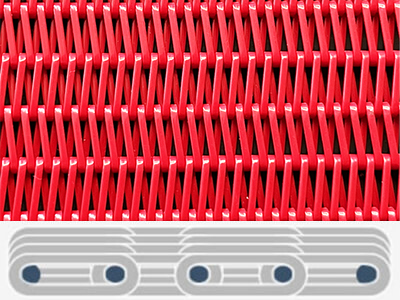

One of the primary techniques involves the careful selection of the belt’s weave and thickness. The weave pattern of polyester fabric can influence air permeability, which is crucial for effective moisture removal. A tighter weave may provide greater structural integrity, but it can also restrict airflow, leading to longer drying times. Conversely, a looser weave enhances air circulation, facilitating quicker moisture evaporation. Therefore, it is essential to strike a balance between strength and permeability, ensuring that the chosen fabric allows for optimal airflow while maintaining the necessary durability for industrial use.

In addition to the weave, the thickness of the polyester belt plays a significant role in drying efficiency. Thinner belts generally allow for faster heat transfer and moisture removal, as they present less material for heat to penetrate. However, they may also be more susceptible to wear and tear, necessitating a careful evaluation of the operational environment. By analyzing the specific requirements of the drying process, manufacturers can select the appropriate belt thickness that maximizes efficiency without compromising longevity.

Another critical aspect of optimizing drying efficiency is the maintenance of the polyester belts. Regular cleaning and inspection are vital to ensure that the belts remain free from contaminants that could impede airflow and moisture removal. Accumulated debris can create barriers that trap moisture, leading to inefficient drying cycles. Implementing a routine maintenance schedule not only prolongs the life of the belts but also enhances their performance, ultimately contributing to improved drying efficiency.

Moreover, the integration of advanced drying technologies can further enhance the effectiveness of polyester fabric belts. For instance, utilizing infrared or microwave drying methods in conjunction with polyester belts can significantly reduce drying times. These technologies work by directly targeting moisture within the material, allowing for quicker evaporation. When combined with the inherent properties of polyester, such as its ability to withstand high temperatures, these methods can lead to substantial improvements in overall drying efficiency.

Furthermore, optimizing the operational parameters of the drying process is essential. Factors such as temperature, humidity, and airflow should be carefully controlled to create an ideal environment for moisture removal. By adjusting these parameters in conjunction with the use of polyester belts, operators can achieve a more efficient drying cycle. For example, increasing the temperature can enhance evaporation rates, while maintaining adequate airflow ensures that moisture is effectively carried away from the material.

In conclusion, enhancing drying efficiency with polyester fabric belts involves a multifaceted approach that encompasses material selection, maintenance, technological integration, and operational optimization. By carefully considering the weave and thickness of the belts, implementing regular maintenance practices, and leveraging advanced drying technologies, industries can significantly improve their drying processes. Ultimately, these techniques not only lead to increased efficiency but also contribute to cost savings and improved product quality, making polyester fabric belts an invaluable asset in modern drying applications.

Maintenance Tips for Prolonging the Life of Polyester Fabric Drying Belts

Polyester fabric belts are widely recognized for their durability and efficiency in various drying applications, particularly in industries such as textiles, food processing, and paper manufacturing. However, to maximize their lifespan and maintain optimal performance, it is essential to implement a comprehensive maintenance strategy. Regular maintenance not only enhances the drying efficiency of these belts but also reduces the likelihood of costly downtime and replacements.

To begin with, routine inspections are crucial for identifying potential issues before they escalate into significant problems. Operators should conduct visual checks of the polyester fabric belts to look for signs of wear, such as fraying edges, discoloration, or surface damage. Additionally, it is advisable to inspect the belt’s alignment and tension regularly. Misalignment can lead to uneven wear and increased stress on the fabric, while improper tension can cause slippage or excessive strain, ultimately shortening the belt’s lifespan. By addressing these issues promptly, operators can ensure that the belts function effectively and efficiently.

Furthermore, cleaning the polyester fabric belts is an essential aspect of maintenance that should not be overlooked. Accumulation of debris, dust, or chemical residues can hinder the drying process and lead to fabric degradation over time. To maintain cleanliness, operators should establish a regular cleaning schedule, utilizing appropriate cleaning agents that are compatible with polyester. It is important to avoid harsh chemicals that could damage the fabric. Instead, a mild detergent and warm water solution can effectively remove contaminants without compromising the integrity of the belt. After cleaning, thorough rinsing and drying are necessary to prevent moisture retention, which could promote mold growth and further deterioration.

In addition to cleaning, lubrication plays a vital role in prolonging the life of polyester fabric belts. While polyester itself does not require lubrication, the components of the drying system, such as rollers and bearings, do. Proper lubrication reduces friction and wear on these components, which in turn minimizes the stress placed on the fabric belt. Operators should follow the manufacturer’s recommendations regarding lubrication intervals and types of lubricants to ensure optimal performance.

Moreover, temperature control is another critical factor in maintaining polyester fabric belts. Excessive heat can weaken the fabric and lead to premature failure. Therefore, it is essential to monitor the drying environment and ensure that temperatures remain within the recommended range for polyester materials. Implementing temperature control measures, such as using thermocouples or infrared sensors, can help maintain optimal conditions and prevent overheating.

Lastly, training personnel on proper handling and operation of the drying system is vital for the longevity of polyester fabric belts. Employees should be educated on the importance of following operational guidelines, including load limits and speed settings. By fostering a culture of awareness and responsibility, organizations can significantly reduce the risk of damage caused by improper use.

In conclusion, maintaining polyester fabric drying belts requires a multifaceted approach that includes regular inspections, cleaning, lubrication, temperature control, and personnel training. By adhering to these maintenance tips, industries can enhance the efficiency of their drying processes while prolonging the life of their polyester fabric belts. Ultimately, a proactive maintenance strategy not only ensures optimal performance but also contributes to cost savings and operational reliability in the long run.