Enhancing Manufacturing with Polyester Spiral Dryer Conveyors

Increased Efficiency in Material Handling

In the realm of modern manufacturing, the quest for increased efficiency in material handling has become paramount. One innovative solution that has emerged to address this need is the polyester spiral dryer conveyor. These conveyors are designed to optimize the drying process of various materials, significantly enhancing productivity and reducing operational costs. By integrating polyester spiral dryer conveyors into manufacturing processes, companies can streamline their operations, ensuring that materials are handled more effectively and efficiently.

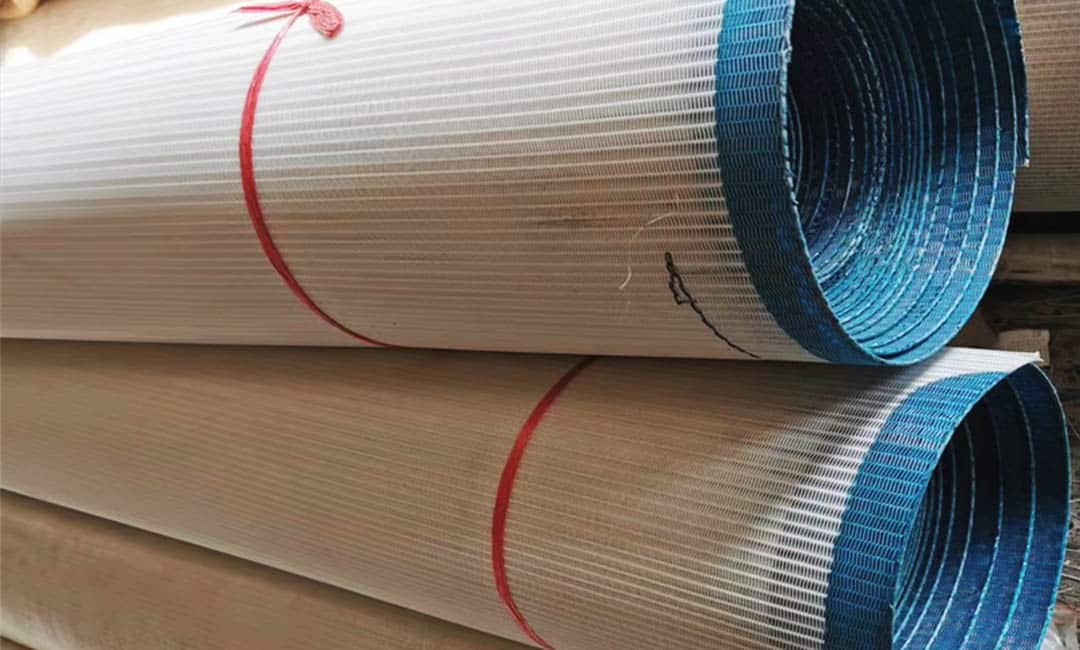

The polyester spiral dryer conveyor operates on a unique principle that allows for continuous drying of materials as they move through the system. This continuous flow not only minimizes the time materials spend in the drying phase but also maximizes the use of available space. Unlike traditional drying methods, which often require large areas and extensive manual handling, the spiral design of these conveyors allows for a compact footprint. This space-saving feature is particularly beneficial in facilities where floor space is at a premium, enabling manufacturers to allocate resources more effectively.

Moreover, the efficiency of polyester spiral dryer conveyors is further enhanced by their ability to maintain consistent drying temperatures. This consistency is crucial in ensuring that materials are dried uniformly, which is essential for maintaining quality standards. In many manufacturing processes, uneven drying can lead to defects, increased waste, and ultimately, higher costs. By utilizing a conveyor system that provides uniform heat distribution, manufacturers can mitigate these risks, resulting in higher quality products and reduced rework.

In addition to improving drying efficiency, polyester spiral dryer conveyors also contribute to the overall automation of manufacturing processes. Automation is a key driver of efficiency in modern manufacturing, as it reduces the need for manual labor and minimizes the potential for human error. By incorporating these conveyors into automated systems, manufacturers can achieve a higher level of precision in material handling. This integration allows for seamless transitions between different stages of production, ensuring that materials are processed quickly and accurately.

Furthermore, the durability and reliability of polyester spiral dryer conveyors play a significant role in enhancing efficiency. Constructed from high-quality materials, these conveyors are designed to withstand the rigors of industrial environments. Their robust design reduces the likelihood of breakdowns and maintenance issues, which can disrupt production schedules and lead to costly downtime. By investing in reliable conveyor systems, manufacturers can ensure that their operations run smoothly, further contributing to overall efficiency.

Another important aspect of polyester spiral dryer conveyors is their adaptability to various manufacturing processes. Whether in the food industry, textile production, or other sectors, these conveyors can be customized to meet specific requirements. This versatility allows manufacturers to implement solutions that are tailored to their unique needs, ensuring that they can handle a wide range of materials effectively. As industries continue to evolve, the ability to adapt to changing demands is crucial for maintaining a competitive edge.

In conclusion, the integration of polyester spiral dryer conveyors into manufacturing processes represents a significant advancement in material handling efficiency. By optimizing drying times, maintaining consistent quality, and enhancing automation, these conveyors provide manufacturers with the tools they need to improve productivity and reduce costs. As the manufacturing landscape continues to evolve, embracing innovative solutions like polyester spiral dryer conveyors will be essential for companies looking to thrive in an increasingly competitive environment. The benefits of these systems extend beyond mere efficiency; they pave the way for a more streamlined, effective, and sustainable approach to manufacturing.

Cost-Effectiveness of Polyester Spiral Dryer Conveyors

Polyester spiral dryer conveyors have emerged as a pivotal innovation in the manufacturing sector, particularly in industries where efficient drying processes are essential. The cost-effectiveness of these conveyors is a significant factor that contributes to their growing popularity. By integrating polyester spiral dryer conveyors into production lines, manufacturers can achieve substantial savings while enhancing operational efficiency. One of the primary advantages of these systems is their ability to optimize energy consumption. Traditional drying methods often require extensive energy input, leading to elevated operational costs. In contrast, polyester spiral dryer conveyors utilize a continuous drying process that minimizes energy usage. This efficiency not only reduces utility bills but also aligns with the increasing emphasis on sustainability in manufacturing practices.

Moreover, the design of polyester spiral dryer conveyors allows for a compact footprint, which is particularly beneficial for facilities with limited space. By maximizing vertical space, these conveyors enable manufacturers to streamline their operations without the need for extensive floor area. This space-saving feature translates into lower real estate costs and allows for more efficient use of existing facilities. Additionally, the modular nature of these systems means that they can be easily integrated into existing production lines, further reducing the need for costly renovations or expansions. As manufacturers seek to remain competitive, the ability to adapt and upgrade equipment without significant financial investment is invaluable.

Another aspect of cost-effectiveness lies in the reduced maintenance requirements of polyester spiral dryer conveyors. Traditional drying systems often involve complex mechanisms that require frequent maintenance and repairs, leading to increased downtime and associated costs. In contrast, polyester spiral dryer conveyors are designed for durability and reliability, which translates into lower maintenance expenses over time. The use of high-quality materials in their construction ensures that these conveyors can withstand the rigors of continuous operation, thereby extending their lifespan and reducing the frequency of replacements. This reliability not only contributes to cost savings but also enhances overall productivity, as manufacturers can rely on consistent performance without the disruptions caused by equipment failures.

Furthermore, the efficiency of polyester spiral dryer conveyors can lead to improved product quality, which is another critical factor in cost-effectiveness. In many manufacturing processes, the quality of the final product is directly linked to the drying process. Inadequate drying can result in defects, leading to increased waste and rework costs. By providing uniform and controlled drying conditions, polyester spiral dryer conveyors help ensure that products meet quality standards, thereby reducing the likelihood of costly errors. This focus on quality not only enhances customer satisfaction but also strengthens a manufacturer’s reputation in the market, ultimately contributing to long-term profitability.

In conclusion, the cost-effectiveness of polyester spiral dryer conveyors is evident through their energy efficiency, space-saving design, reduced maintenance needs, and ability to enhance product quality. As manufacturers continue to seek ways to optimize their operations and reduce costs, the adoption of these innovative drying solutions presents a compelling opportunity. By investing in polyester spiral dryer conveyors, companies can not only achieve immediate financial benefits but also position themselves for sustainable growth in an increasingly competitive landscape. The integration of such advanced technologies is not merely a trend; it represents a strategic move towards more efficient and cost-effective manufacturing processes that can yield significant returns on investment over time.

Improved Product Quality and Consistency

In the realm of manufacturing, the quest for improved product quality and consistency is paramount. One innovative solution that has emerged to address these challenges is the polyester spiral dryer conveyor. This technology not only enhances the efficiency of the drying process but also significantly contributes to the overall quality of the final product. By utilizing a polyester spiral dryer conveyor, manufacturers can achieve a more uniform drying process, which is essential for maintaining the integrity of various materials.

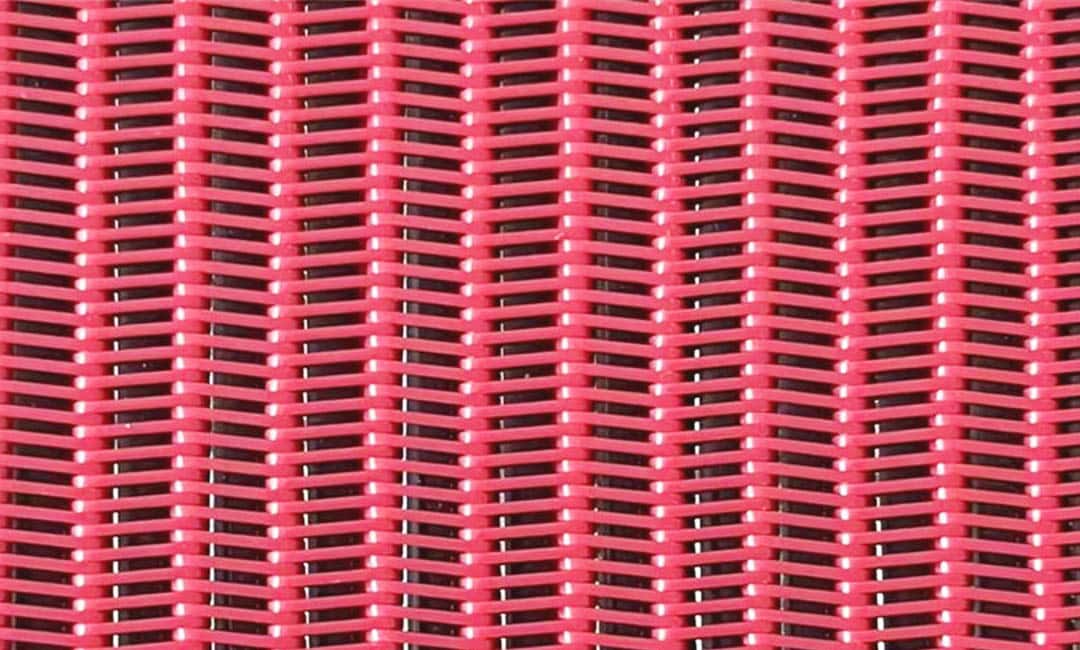

The design of polyester spiral dryer conveyors allows for a continuous and controlled drying environment. This is particularly beneficial in industries where moisture content is critical, such as food processing, textiles, and paper manufacturing. The spiral configuration of the conveyor ensures that products are evenly exposed to heat and airflow, minimizing the risk of over-drying or under-drying. As a result, manufacturers can produce items with consistent moisture levels, which directly impacts the quality of the end product. For instance, in the food industry, maintaining the right moisture content is crucial for flavor, texture, and shelf life.

Moreover, the polyester material used in these conveyors offers several advantages over traditional drying methods. Polyester is known for its durability and resistance to wear, which translates to a longer lifespan for the conveyor system. This durability reduces the frequency of maintenance and replacement, allowing manufacturers to focus on production rather than equipment upkeep. Additionally, polyester is lightweight, which contributes to lower energy consumption during operation. This energy efficiency not only reduces operational costs but also aligns with the growing emphasis on sustainability in manufacturing practices.

Another significant aspect of polyester spiral dryer conveyors is their ability to accommodate a wide range of products. Whether dealing with delicate textiles or robust industrial materials, these conveyors can be tailored to meet specific drying requirements. This versatility ensures that manufacturers can maintain high standards of quality across different product lines. Furthermore, the adaptability of the conveyor system allows for quick adjustments in response to varying production demands, thereby enhancing overall operational efficiency.

In addition to improving product quality, polyester spiral dryer conveyors also play a crucial role in ensuring consistency throughout the manufacturing process. Consistency is vital for building customer trust and satisfaction, as consumers expect uniformity in the products they purchase. By implementing a reliable drying solution, manufacturers can minimize variations in product quality, leading to a more predictable output. This predictability not only enhances brand reputation but also facilitates better inventory management and forecasting.

The integration of polyester spiral dryer conveyors into manufacturing processes represents a significant advancement in technology. As industries continue to evolve, the need for innovative solutions that enhance product quality and consistency becomes increasingly important. By investing in such systems, manufacturers can not only improve their operational efficiency but also ensure that they meet the ever-growing demands of consumers for high-quality products. In conclusion, the adoption of polyester spiral dryer conveyors is a strategic move that can lead to substantial improvements in product quality and consistency, ultimately benefiting both manufacturers and consumers alike. As the manufacturing landscape continues to change, embracing such advancements will be crucial for staying competitive and meeting the expectations of the market.