Essential Rosin Bag Press Tips for Cleaner & Stronger Concentrates

Proper Temperature Control

When it comes to producing high-quality rosin concentrates, proper temperature control is paramount. The temperature at which you press your material can significantly influence the yield, flavor, and overall quality of the final product. Understanding the nuances of temperature control can help you achieve cleaner and stronger concentrates, making it an essential aspect of the rosin pressing process.

To begin with, it is crucial to recognize that different materials require different temperature settings. For instance, flower typically benefits from lower temperatures, generally ranging from 180°F to 220°F. This range allows for the preservation of terpenes, which are responsible for the aroma and flavor of the concentrate. By pressing at lower temperatures, you can extract a more flavorful product while minimizing the risk of burning the plant material. Conversely, when working with hash or kief, slightly higher temperatures, around 220°F to 250°F, can be more effective. The increased heat helps to break down the trichomes more efficiently, resulting in a higher yield without compromising quality.

Moreover, it is essential to maintain a consistent temperature throughout the pressing process. Fluctuations in temperature can lead to uneven extraction, which may result in a product that is either too harsh or lacks potency. To achieve this consistency, using a reliable heat source is vital. Electric heat plates are often preferred over other methods, as they provide precise temperature control and even heat distribution. Additionally, investing in a quality thermometer can help you monitor the temperature accurately, ensuring that you remain within the desired range throughout the pressing process.

In addition to the type of material and the heat source, the duration of the press also plays a critical role in temperature control. A longer pressing time at lower temperatures can yield a more flavorful concentrate, while shorter pressing times at higher temperatures may produce a more potent product. However, it is essential to strike a balance; pressing for too long can lead to the degradation of terpenes and the formation of undesirable compounds. Therefore, experimenting with different pressing times at various temperatures can help you find the optimal combination for your specific material.

Furthermore, preheating your rosin bags and material can enhance the overall efficiency of the pressing process. By allowing the material to reach the desired temperature before applying pressure, you can facilitate a more effective extraction. This preheating step can also help to reduce the risk of moisture retention, which can negatively impact the quality of the concentrate. It is advisable to allow your material to acclimate to room temperature before pressing, as this can further improve the consistency of the extraction.

Lastly, it is important to document your pressing parameters, including temperature, time, and material type. Keeping a detailed log of your experiments will enable you to refine your technique over time. By analyzing the results of different pressing sessions, you can identify patterns and make informed adjustments to your process. This systematic approach will ultimately lead to a better understanding of how temperature control affects the quality of your rosin concentrates.

In conclusion, mastering proper temperature control is essential for producing cleaner and stronger rosin concentrates. By understanding the specific needs of your material, maintaining consistent temperatures, and carefully monitoring pressing times, you can significantly enhance the quality of your final product. With practice and attention to detail, you will be well on your way to achieving exceptional rosin concentrates that showcase the full potential of your starting material.

Choosing the Right Rosin Bag Size

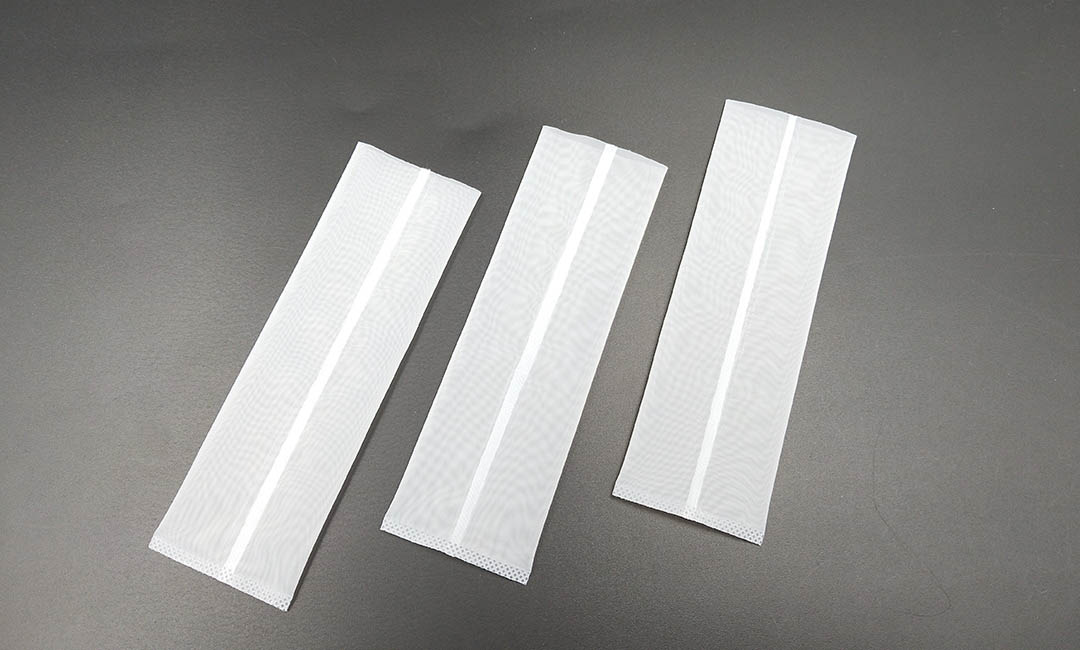

When it comes to making high-quality concentrates, using a rosin bag press is essential. These bags help to filter out plant material and impurities, resulting in cleaner and stronger concentrates. However, choosing the right rosin bag size is crucial to achieving the best results. In this article, we will discuss some essential tips for selecting the right rosin bag size for your pressing needs.

One of the most important factors to consider when choosing a rosin bag size is the type of material you are pressing. Different materials require different sizes of bags to achieve optimal results. For example, if you are pressing fine kief or sift, a smaller bag size is recommended to prevent the material from leaking out during the pressing process. On the other hand, if you are pressing larger quantities of flower or trim, a larger bag size will be necessary to accommodate the volume of material.

Another important consideration when choosing a rosin bag size is the pressure you will be applying during the pressing process. Higher pressures require larger bags to prevent blowouts and ensure that the material is evenly distributed within the bag. It is important to choose a bag size that can withstand the pressure you will be applying without bursting or tearing.

Additionally, the size of your rosin press plates will also play a role in determining the appropriate bag size. The bags should be slightly smaller than the plates to allow for proper heat distribution and prevent the bags from getting caught in the press. It is recommended to measure the size of your plates before purchasing rosin bags to ensure a proper fit.

When selecting a rosin bag size, it is also important to consider the micron rating of the bag. The micron rating refers to the size of the filter pores in the bag and determines the level of filtration that will be achieved. Lower micron ratings provide finer filtration, resulting in cleaner concentrates, while higher micron ratings allow for more material to pass through the filter. It is important to choose a bag with the appropriate micron rating for the type of material you are pressing to achieve the desired level of purity.

In conclusion, choosing the right rosin bag size is essential for producing cleaner and stronger concentrates. Consider the type of material you are pressing, the pressure you will be applying, the size of your press plates, and the micron rating of the bag when selecting the appropriate size. By following these tips, you can ensure that your pressing process is efficient and effective, resulting in high-quality concentrates every time.

Optimal Pressure Application

When it comes to making high-quality concentrates, using a rosin bag press is essential. This tool allows you to extract the maximum amount of resin from your plant material, resulting in cleaner and stronger concentrates. However, to achieve the best results, it is crucial to apply the right amount of pressure during the pressing process. In this article, we will discuss some essential tips for optimal pressure application when using a rosin bag press.

One of the most important factors to consider when applying pressure is the type of material you are pressing. Different materials require different levels of pressure to extract the resin effectively. For example, softer materials like kief or bubble hash may require less pressure, while harder materials like flower or trim may require more pressure. It is essential to experiment with different pressure levels to find the optimal setting for the material you are working with.

Another crucial tip for optimal pressure application is to evenly distribute the pressure across the entire surface of the material. Uneven pressure can result in an uneven extraction, leading to lower-quality concentrates. To ensure even pressure distribution, it is recommended to use a press with a large surface area or to apply pressure in multiple stages. This will help to ensure that the resin is extracted evenly and efficiently.

It is also important to monitor the temperature of the press during the pressing process. High temperatures can cause the resin to degrade, resulting in lower-quality concentrates. It is recommended to use a press with temperature control settings and to keep the temperature within the optimal range for the material you are pressing. This will help to preserve the quality of the resin and produce cleaner and stronger concentrates.

In addition to monitoring the temperature, it is essential to pay attention to the time of the pressing process. Pressing for too long can result in over-extraction, leading to a decrease in quality. On the other hand, pressing for too short a time may not extract enough resin, resulting in lower yields. It is recommended to experiment with different pressing times to find the optimal duration for the material you are working with.

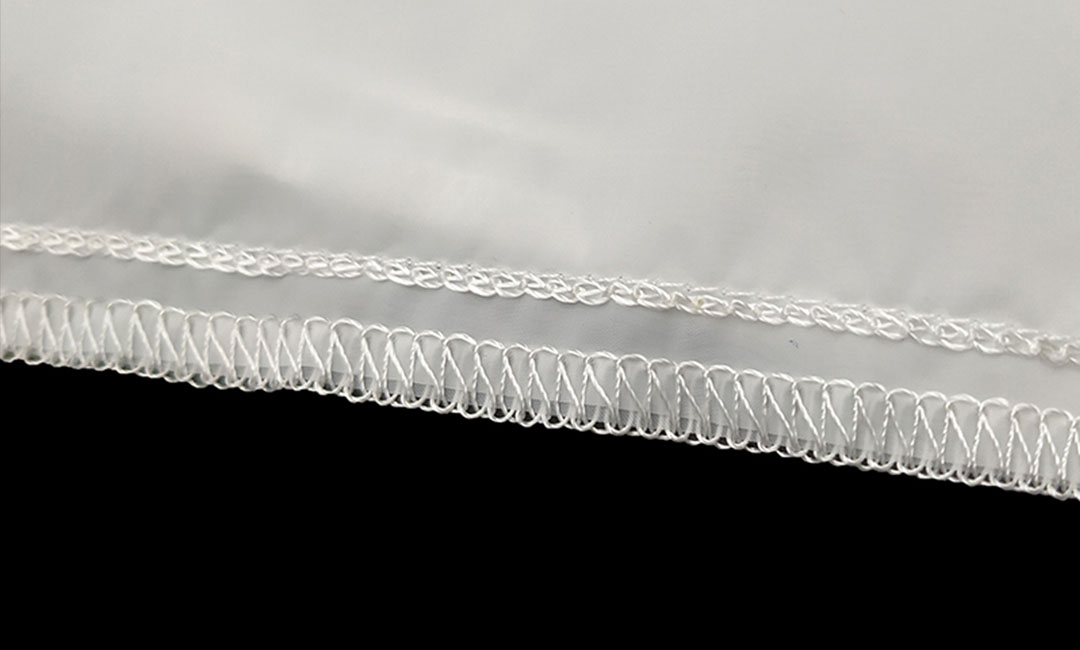

Lastly, it is crucial to use high-quality rosin bags when pressing your material. Low-quality bags can break or tear during the pressing process, leading to contamination of the resin and lower-quality concentrates. It is recommended to use bags made from durable materials like nylon or polyester and to replace them regularly to ensure optimal results.

In conclusion, applying the right amount of pressure is essential for producing cleaner and stronger concentrates with a rosin bag press. By considering factors such as material type, pressure distribution, temperature, pressing time, and bag quality, you can achieve optimal results and maximize the quality of your concentrates. Experimenting with different settings and techniques will help you find the perfect balance for your specific needs and preferences. With these essential tips in mind, you can take your concentrate production to the next level and enjoy high-quality extracts every time.

Cleaning and Maintaining Your Equipment

Cleaning and maintaining your rosin bag press equipment is crucial for achieving cleaner and stronger concentrates. The quality of your final product is directly influenced by the condition of your tools, making regular maintenance an essential practice for any serious extractor. To begin with, it is important to understand that rosin presses, like any other equipment, accumulate residue over time. This residue can affect the purity and flavor of your concentrates, so a systematic cleaning routine is necessary.

First and foremost, after each pressing session, it is advisable to allow your equipment to cool down before attempting any cleaning. This precaution not only protects you from burns but also ensures that any residual material is easier to remove when it is not hot. Once the equipment has cooled, you can start by wiping down the plates with a clean, lint-free cloth. This step is vital, as it removes any leftover plant material or oils that may have adhered to the surface during the pressing process. For more stubborn residues, a small amount of isopropyl alcohol can be used to break down the oils, but it is essential to ensure that no alcohol remains on the plates before the next use.

In addition to cleaning the plates, attention should also be given to the rosin bags themselves. These bags can trap oils and plant material, which can lead to contamination in future extractions. After each use, it is recommended to rinse the bags with warm water to remove any residual material. For a more thorough cleaning, soaking the bags in a solution of warm water and mild soap can help to eliminate any stubborn residues. After soaking, rinse the bags thoroughly to ensure that no soap remains, as this could affect the flavor of your concentrates.

Furthermore, the hydraulic system of your rosin press requires regular maintenance to ensure optimal performance. It is advisable to check the hydraulic fluid levels periodically and replace the fluid as needed. Contaminated or low hydraulic fluid can lead to inefficient pressing and may even damage the equipment over time. Additionally, inspecting the hoses and connections for any signs of wear or leaks is crucial. Addressing these issues promptly can prevent more significant problems down the line.

Moreover, the frame and exterior of the rosin press should not be neglected. Dust and debris can accumulate on the surface, which not only detracts from the appearance of your equipment but can also lead to operational issues. A simple wipe down with a damp cloth can keep the exterior clean and free from contaminants. It is also beneficial to periodically check for any loose screws or bolts, as vibrations during operation can cause components to loosen over time.

In conclusion, maintaining a clean and well-functioning rosin bag press is essential for producing high-quality concentrates. By implementing a regular cleaning routine for both the pressing plates and rosin bags, as well as ensuring the hydraulic system is in good condition, you can significantly enhance the quality of your extractions. Taking the time to care for your equipment not only prolongs its lifespan but also ensures that each pressing yields the purest and most potent concentrates possible. Ultimately, a commitment to cleanliness and maintenance will pay off in the form of superior products and a more efficient extraction process.