Exploring Material Options for High Flow Pleated Cartridges

Benefits of Using Polypropylene Material for High Flow Pleated Cartridges

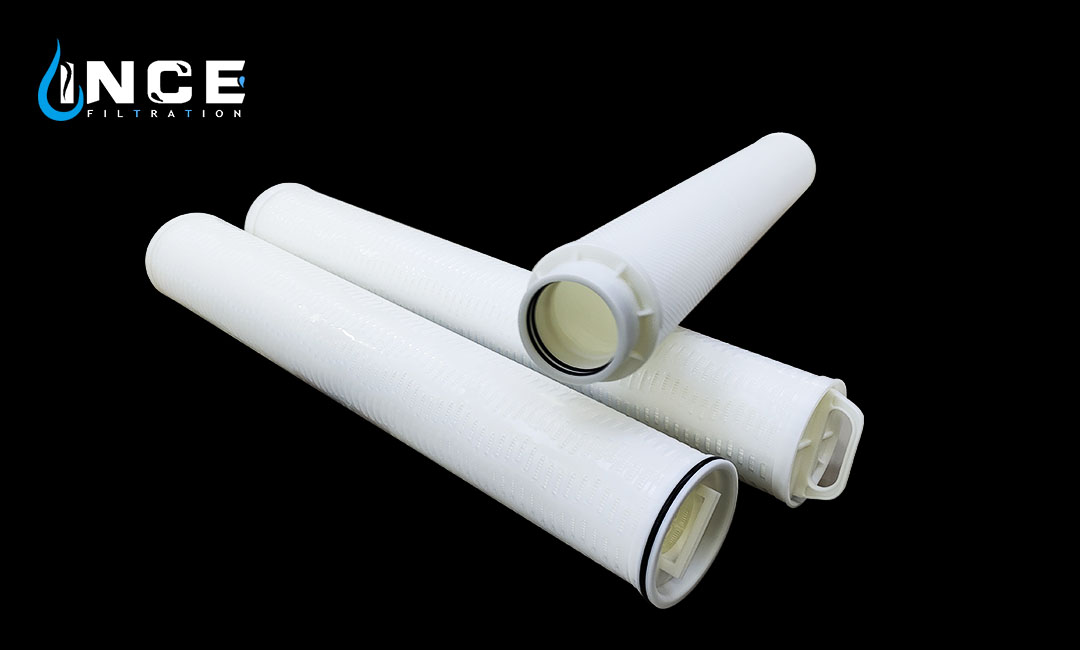

High flow pleated cartridges are essential components in many industrial filtration systems, providing efficient filtration of liquids and gases. When selecting a material for these cartridges, it is important to consider factors such as chemical compatibility, temperature resistance, and flow rates. One material that is commonly used for high flow pleated cartridges is polypropylene, due to its many benefits and advantages.

Polypropylene is a thermoplastic polymer that is known for its excellent chemical resistance, making it ideal for use in a wide range of industrial applications. It is resistant to a variety of chemicals, including acids, bases, and solvents, making it a versatile material for high flow pleated cartridges. This chemical resistance ensures that the cartridges will not degrade or break down when exposed to harsh chemicals, ensuring the longevity and effectiveness of the filtration system.

In addition to its chemical resistance, polypropylene is also known for its high temperature resistance, making it suitable for use in applications where high temperatures are present. This temperature resistance ensures that the cartridges will not deform or melt when exposed to elevated temperatures, maintaining their structural integrity and filtration efficiency. This is particularly important in industrial settings where high temperatures are common, ensuring that the filtration system can operate effectively under these conditions.

Another benefit of using polypropylene for high flow pleated cartridges is its high flow rates. Polypropylene has a smooth surface that allows for high flow rates, ensuring that liquids and gases can pass through the cartridges quickly and efficiently. This high flow rate helps to minimize pressure drop across the filtration system, reducing energy consumption and ensuring optimal performance. Additionally, the high flow rate of polypropylene cartridges allows for faster filtration, increasing productivity and efficiency in industrial processes.

Polypropylene is also a lightweight material, making it easy to handle and install in filtration systems. Its lightweight nature reduces the strain on equipment and personnel during installation and maintenance, making it a practical choice for high flow pleated cartridges. Additionally, polypropylene is a cost-effective material, offering a balance of performance and affordability for industrial applications. Its durability and longevity ensure that the cartridges will last for an extended period, reducing the need for frequent replacements and maintenance.

Overall, polypropylene offers a range of benefits for high flow pleated cartridges, making it a popular choice for industrial filtration systems. Its chemical resistance, temperature resistance, high flow rates, lightweight nature, and cost-effectiveness make it an ideal material for a wide range of applications. By choosing polypropylene for high flow pleated cartridges, industrial facilities can ensure efficient filtration, optimal performance, and cost savings in their operations.

Exploring the Durability of Polyester Material in High Flow Pleated Cartridges

High flow pleated cartridges are essential components in many industrial filtration systems, providing efficient filtration of liquids and gases. When selecting a high flow pleated cartridge, one of the key considerations is the material used in its construction. Polyester is a popular material choice for high flow pleated cartridges due to its durability and chemical resistance.

Polyester is a synthetic material that is known for its strength and resistance to abrasion, making it an ideal choice for high flow pleated cartridges that are subjected to high pressure and flow rates. Additionally, polyester is resistant to a wide range of chemicals, making it suitable for use in a variety of industrial applications where exposure to corrosive substances is a concern.

One of the key advantages of polyester material in high flow pleated cartridges is its durability. Polyester is a strong material that can withstand high pressure and flow rates without deforming or collapsing. This durability ensures that the pleated cartridge maintains its structural integrity over time, providing consistent and reliable filtration performance.

In addition to its durability, polyester material is also resistant to microbial growth, making it an ideal choice for applications where cleanliness is a priority. The smooth surface of polyester material inhibits the growth of bacteria and other microorganisms, ensuring that the filtration process remains hygienic and efficient.

Another benefit of polyester material in high flow pleated cartridges is its thermal stability. Polyester can withstand a wide range of temperatures without degrading, making it suitable for use in both hot and cold filtration applications. This thermal stability ensures that the pleated cartridge maintains its performance even in extreme temperature conditions.

Despite its many advantages, polyester material does have some limitations. One of the main drawbacks of polyester is its limited compatibility with certain solvents and chemicals. While polyester is resistant to a wide range of chemicals, it may not be suitable for use in applications where exposure to specific chemicals is a concern. In such cases, it is important to consider alternative material options that offer greater chemical resistance.

Overall, polyester material is a durable and reliable choice for high flow pleated cartridges. Its strength, chemical resistance, and thermal stability make it an ideal material for a wide range of industrial filtration applications. However, it is important to carefully consider the specific requirements of your application and select a material that best meets your needs. By exploring the durability of polyester material in high flow pleated cartridges, you can ensure that your filtration system operates efficiently and effectively.

Considerations When Choosing Nylon Material for High Flow Pleated Cartridges

Considerations When Choosing Nylon Material for High Flow Pleated Cartridges

When it comes to high flow pleated cartridges, choosing the right material is crucial. One material that is often considered is nylon. Nylon is a synthetic polymer that offers a range of benefits for high flow applications. However, there are several important considerations to keep in mind when choosing nylon as the material for your high flow pleated cartridges.

First and foremost, it is important to consider the temperature limitations of nylon. Nylon has a relatively low melting point, typically around 220-250 degrees Celsius. This means that if your application involves high temperatures, nylon may not be the best choice. It is important to ensure that the operating temperature of your system is within the limits of the nylon material to avoid any potential issues.

Another consideration when choosing nylon for high flow pleated cartridges is its chemical compatibility. Nylon is generally resistant to a wide range of chemicals, including acids, bases, and solvents. However, it is important to check the compatibility of nylon with the specific chemicals that will be present in your application. Some chemicals, such as strong acids or certain organic solvents, may degrade or weaken the nylon material over time. It is crucial to ensure that the nylon material is compatible with the chemicals in your system to avoid any potential failures or contamination.

In addition to temperature and chemical compatibility, it is also important to consider the mechanical properties of nylon. Nylon is known for its high strength and durability, making it an excellent choice for high flow applications. It has good resistance to abrasion and impact, which is important for maintaining the integrity of the pleated cartridges over time. However, it is important to consider the specific requirements of your application and ensure that the mechanical properties of nylon are suitable for your needs.

One potential drawback of nylon is its moisture absorption. Nylon has a tendency to absorb moisture from the environment, which can affect its dimensional stability and mechanical properties. This can be a concern in high humidity environments or applications where the pleated cartridges may be exposed to water or other liquids. It is important to take this into consideration and ensure that the nylon material is properly sealed or coated to prevent moisture absorption.

Lastly, cost is always an important consideration when choosing materials for any application. Nylon is generally a cost-effective option compared to other high-performance materials such as stainless steel or PTFE. However, it is important to weigh the cost against the specific requirements of your application. If the benefits of nylon outweigh the cost considerations, it may be the right choice for your high flow pleated cartridges.

In conclusion, nylon is a popular material choice for high flow pleated cartridges due to its temperature resistance, chemical compatibility, mechanical properties, and cost-effectiveness. However, it is important to carefully consider the specific requirements of your application and ensure that nylon is the right material choice. By considering factors such as temperature limitations, chemical compatibility, mechanical properties, moisture absorption, and cost, you can make an informed decision and select the best material for your high flow pleated cartridges.

Impact of Using Fiberglass Material in High Flow Pleated Cartridges

High flow pleated cartridges are essential components in many industrial filtration systems, providing efficient filtration of liquids and gases. When selecting material options for these cartridges, it is crucial to consider the impact of using fiberglass material. Fiberglass is a popular choice for high flow pleated cartridges due to its excellent chemical resistance, high temperature tolerance, and durability.

One of the key advantages of using fiberglass material in high flow pleated cartridges is its exceptional chemical resistance. Fiberglass is highly resistant to a wide range of chemicals, making it ideal for applications where exposure to corrosive substances is a concern. This resistance ensures that the cartridges maintain their structural integrity and filtration efficiency even in harsh chemical environments.

In addition to its chemical resistance, fiberglass material also offers high temperature tolerance. High flow pleated cartridges are often used in industrial processes that involve high temperatures, and fiberglass can withstand these extreme conditions without compromising its performance. This thermal stability ensures that the cartridges can effectively filter hot liquids and gases without degrading or melting.

Furthermore, fiberglass material is known for its durability and longevity. High flow pleated cartridges made from fiberglass are highly durable and can withstand the rigors of industrial filtration applications. This durability translates to longer service life and reduced maintenance costs, making fiberglass a cost-effective choice for high flow filtration systems.

Despite its many advantages, there are some considerations to keep in mind when using fiberglass material in high flow pleated cartridges. One potential drawback is the risk of fiber shedding, which can occur when the cartridges are subjected to high flow rates or abrasive fluids. Fiber shedding can lead to contamination of the filtered product and compromise the efficiency of the filtration system.

To mitigate the risk of fiber shedding, it is important to select high-quality fiberglass material and ensure proper cartridge design and construction. Additionally, regular maintenance and monitoring of the cartridges can help detect any signs of fiber shedding early on and prevent potential issues.

In conclusion, fiberglass material offers several benefits for high flow pleated cartridges, including excellent chemical resistance, high temperature tolerance, and durability. However, it is essential to be aware of the potential risk of fiber shedding and take appropriate measures to prevent it. By carefully considering the impact of using fiberglass material and implementing proper maintenance practices, high flow pleated cartridges can provide reliable and efficient filtration in a wide range of industrial applications.