Exploring the Technology Behind Ultipleat High Flow Filters

Benefits of Using Ultipleat High Flow Filters in Industrial Applications

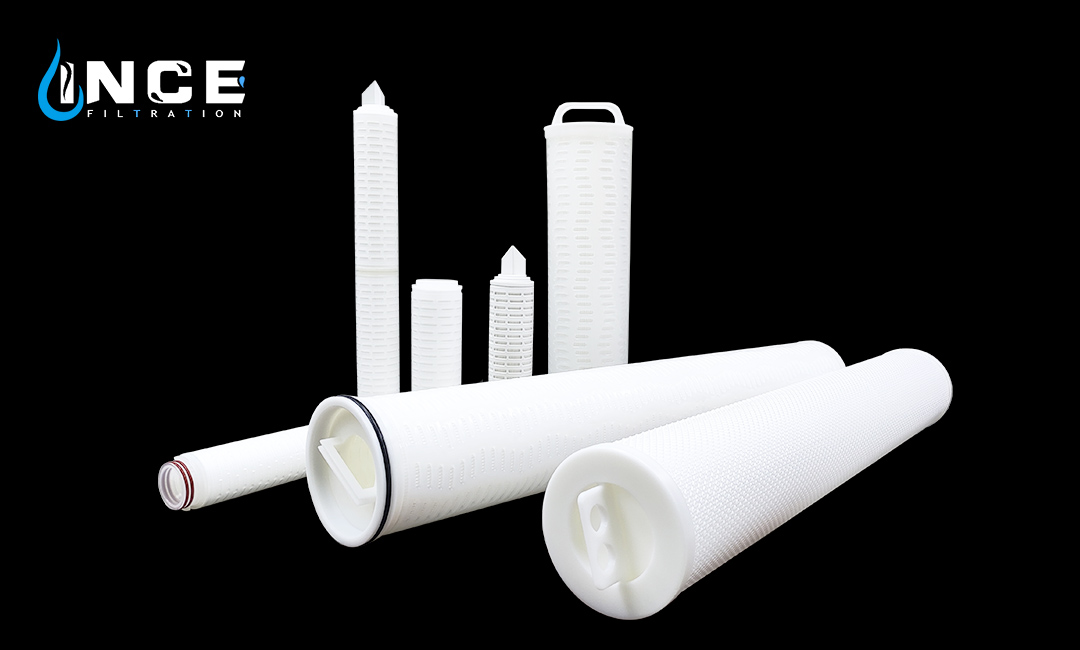

In the world of industrial filtration, Ultipleat High Flow Filters have become a popular choice for many companies looking to improve their filtration processes. These filters are designed to handle high flow rates while maintaining efficiency and effectiveness in removing contaminants from liquids. In this article, we will explore the technology behind Ultipleat High Flow Filters and discuss the benefits of using them in industrial applications.

One of the key features of Ultipleat High Flow Filters is their unique design, which allows for a larger surface area compared to traditional filters. This increased surface area enables the filters to handle higher flow rates without sacrificing filtration efficiency. The filters are made up of multiple layers of pleated media, which provide a greater filtration area for capturing contaminants. This design also helps to reduce pressure drop across the filter, resulting in lower energy consumption and cost savings for the company.

Another important aspect of Ultipleat High Flow Filters is their ability to remove a wide range of contaminants from liquids. These filters are available in various micron ratings, allowing companies to choose the right filter for their specific application. Whether it’s removing particles, bacteria, or other impurities, Ultipleat High Flow Filters can effectively clean the liquid and ensure a high level of purity.

In addition to their superior filtration capabilities, Ultipleat High Flow Filters are also known for their durability and longevity. These filters are constructed using high-quality materials that can withstand harsh operating conditions and maintain their performance over time. This durability not only reduces maintenance costs but also ensures consistent filtration results for the company.

One of the main benefits of using Ultipleat High Flow Filters in industrial applications is their cost-effectiveness. While the initial investment may be higher compared to traditional filters, the long-term savings in energy consumption, maintenance, and replacement costs make these filters a cost-effective solution for companies. By choosing Ultipleat High Flow Filters, companies can improve their filtration processes while reducing overall operating costs.

Furthermore, Ultipleat High Flow Filters are easy to install and replace, making them a convenient option for companies looking to streamline their filtration systems. The filters can be quickly changed out without the need for specialized tools or equipment, saving time and labor costs for the company. This ease of use also minimizes downtime and ensures continuous operation of the filtration system.

In conclusion, Ultipleat High Flow Filters offer a range of benefits for companies in industrial applications. From their superior filtration capabilities to their cost-effectiveness and ease of use, these filters are a reliable and efficient solution for improving filtration processes. By understanding the technology behind Ultipleat High Flow Filters and the advantages they offer, companies can make informed decisions about incorporating these filters into their operations.

How Ultipleat High Flow Filters Improve Filtration Efficiency

Ultipleat High Flow Filters are a cutting-edge technology that has revolutionized the filtration industry. These filters are designed to improve filtration efficiency and provide superior performance compared to traditional filters. In this article, we will explore the technology behind Ultipleat High Flow Filters and how they work to enhance filtration processes.

One of the key features of Ultipleat High Flow Filters is their large surface area. These filters are designed with a pleated design that increases the available filtration area, allowing for greater flow rates and improved efficiency. The pleated design also helps to reduce pressure drop, ensuring that the filtration process is not hindered by excessive resistance.

In addition to their large surface area, Ultipleat High Flow Filters are constructed using high-quality materials that are designed to withstand harsh operating conditions. These filters are made from durable materials such as polypropylene, polyester, and nylon, which are resistant to chemicals, solvents, and high temperatures. This ensures that the filters can effectively remove contaminants from a wide range of fluids without compromising their performance.

Another key technology behind Ultipleat High Flow Filters is their innovative design. These filters are engineered with a graded density structure that allows for efficient particle capture and retention. The outer layers of the filter have a larger pore size to capture larger particles, while the inner layers have a smaller pore size to capture smaller particles. This graded density structure ensures that contaminants of all sizes are effectively removed from the fluid, resulting in cleaner and purer filtrate.

Ultipleat High Flow Filters also feature a unique core design that enhances their performance. The core of the filter is designed to provide structural support and prevent collapse under high flow rates. This ensures that the filter maintains its integrity and efficiency even under demanding operating conditions. The core also helps to distribute flow evenly across the filter, preventing channeling and ensuring uniform filtration throughout the entire filter media.

One of the main advantages of Ultipleat High Flow Filters is their high flow rates. These filters are capable of handling flow rates that are significantly higher than traditional filters, making them ideal for applications that require fast and efficient filtration. The large surface area and graded density structure of Ultipleat High Flow Filters allow for high flow rates without sacrificing filtration efficiency, making them a versatile and reliable choice for a wide range of industries.

In conclusion, Ultipleat High Flow Filters are a technological advancement that has greatly improved filtration efficiency. Their large surface area, durable materials, innovative design, and high flow rates make them a superior choice for applications that require efficient and reliable filtration. By understanding the technology behind Ultipleat High Flow Filters, industries can make informed decisions about their filtration needs and choose a filter that will provide optimal performance and results.

Comparing Ultipleat High Flow Filters to Traditional Filtration Methods

In the world of filtration technology, Ultipleat High Flow Filters have emerged as a cutting-edge solution for a wide range of industrial applications. These filters offer a number of advantages over traditional filtration methods, making them a popular choice for companies looking to improve their filtration processes.

One of the key differences between Ultipleat High Flow Filters and traditional filtration methods is their design. Traditional filters typically consist of a single filter element, which can become clogged and require frequent replacement. Ultipleat High Flow Filters, on the other hand, feature multiple filter elements housed within a single housing. This design allows for a larger filtration area, resulting in higher flow rates and longer filter life.

Another advantage of Ultipleat High Flow Filters is their ability to remove a wide range of contaminants from the fluid being filtered. Traditional filters are often limited in the types of contaminants they can effectively remove, leading to reduced filtration efficiency. Ultipleat High Flow Filters, however, are capable of removing particles as small as 1 micron, making them ideal for applications where fine filtration is required.

In addition to their superior filtration capabilities, Ultipleat High Flow Filters are also more cost-effective than traditional filters. Because they have a longer filter life and require less frequent replacement, companies can save money on filter maintenance and replacement costs. This can result in significant cost savings over time, making Ultipleat High Flow Filters a smart investment for companies looking to improve their filtration processes.

Ultipleat High Flow Filters are also more environmentally friendly than traditional filters. Because they require less frequent replacement, there is less waste generated from filter disposal. Additionally, the higher flow rates of Ultipleat High Flow Filters can result in reduced energy consumption, further reducing their environmental impact.

Overall, Ultipleat High Flow Filters offer a number of advantages over traditional filtration methods. Their innovative design, superior filtration capabilities, cost-effectiveness, and environmental friendliness make them a popular choice for companies looking to improve their filtration processes. Whether you are in the pharmaceutical, food and beverage, chemical, or any other industry that requires high-quality filtration, Ultipleat High Flow Filters are a technology worth exploring.

The Impact of Ultipleat High Flow Filters on Maintenance Costs and Downtime

Ultipleat High Flow Filters are a revolutionary technology that has been making waves in the industrial filtration industry. These filters are designed to handle high flow rates while maintaining efficiency and reliability. In this article, we will explore the technology behind Ultipleat High Flow Filters and their impact on maintenance costs and downtime.

One of the key features of Ultipleat High Flow Filters is their unique design. These filters are equipped with a large surface area, which allows them to handle high flow rates without sacrificing filtration efficiency. This design also helps to reduce pressure drop, which can lead to energy savings and increased system performance.

Another important aspect of Ultipleat High Flow Filters is their advanced filtration media. These filters are available in a variety of media options, including pleated polypropylene, glass fiber, and stainless steel. Each of these media types offers different levels of filtration efficiency and compatibility with various fluids and contaminants.

In addition to their innovative design and filtration media, Ultipleat High Flow Filters are also equipped with a self-cleaning mechanism. This feature helps to extend the life of the filter and reduce maintenance requirements. By automatically cleaning the filter media, these filters can operate for longer periods without the need for manual intervention.

The impact of Ultipleat High Flow Filters on maintenance costs and downtime is significant. By reducing the frequency of filter changes and minimizing the need for manual cleaning, these filters can help to lower maintenance costs and increase operational efficiency. This can result in significant cost savings for industrial facilities that rely on high flow filtration systems.

Furthermore, the self-cleaning mechanism of Ultipleat High Flow Filters helps to reduce downtime associated with filter maintenance. With fewer filter changes and less manual cleaning required, these filters can help to keep production lines running smoothly and minimize disruptions to operations. This can lead to increased productivity and improved overall performance for industrial facilities.

Overall, Ultipleat High Flow Filters offer a cost-effective and efficient solution for high flow filtration applications. Their innovative design, advanced filtration media, and self-cleaning mechanism make them a valuable asset for industrial facilities looking to improve their filtration systems. By reducing maintenance costs and downtime, these filters can help to optimize system performance and maximize operational efficiency.

In conclusion, Ultipleat High Flow Filters are a game-changer in the world of industrial filtration. Their advanced technology and innovative design make them a reliable and cost-effective solution for high flow filtration applications. By reducing maintenance costs and downtime, these filters can help industrial facilities improve their operational efficiency and achieve greater productivity.