Finding Liquid Bag Filter Housings: A Comprehensive Overview

Types Of Liquid Bag Filter Housings

When it comes to liquid filtration, the choice of bag filter housing is crucial for ensuring optimal performance and efficiency. Various types of liquid bag filter housings are available, each designed to meet specific operational requirements and applications. Understanding these different types can significantly enhance the filtration process and contribute to the overall effectiveness of a system.

One of the most common types of liquid bag filter housings is the single-bag filter housing. This design is straightforward and typically accommodates one filter bag at a time. Single-bag housings are ideal for applications where the flow rate is moderate and the filtration needs are not overly complex. They are often used in industries such as food and beverage, pharmaceuticals, and water treatment, where simplicity and ease of maintenance are paramount. The straightforward design allows for quick bag changes, minimizing downtime and ensuring continuous operation.

In contrast, multi-bag filter housings are designed to hold multiple filter bags simultaneously, making them suitable for high-flow applications. These housings can accommodate anywhere from two to several dozen bags, depending on the specific model and design. Multi-bag housings are particularly advantageous in industrial settings where large volumes of liquid need to be filtered efficiently. The ability to filter multiple bags at once not only increases the filtration capacity but also extends the service life of the filter media, as the load is distributed across several bags. This design is commonly found in sectors such as chemical processing, oil and gas, and wastewater treatment.

Another important type of liquid bag filter housing is the duplex filter housing. This design features two separate filter chambers, allowing for continuous operation even during maintenance. When one bag needs to be replaced or cleaned, the flow can be diverted to the other chamber, ensuring that the filtration process remains uninterrupted. Duplex filter housings are particularly beneficial in applications where downtime is not an option, such as in critical processes in pharmaceuticals or food production. The ability to switch between chambers enhances operational efficiency and reliability.

Moreover, there are specialized bag filter housings designed for specific applications. For instance, high-temperature and high-pressure bag filter housings are engineered to withstand extreme conditions, making them suitable for industries such as petrochemicals and power generation. These housings are constructed from robust materials that can endure harsh environments, ensuring safety and longevity. Additionally, there are sanitary bag filter housings that comply with stringent hygiene standards, making them ideal for the food and beverage industry, as well as pharmaceuticals. These housings are designed to facilitate easy cleaning and maintenance, thereby preventing contamination.

Furthermore, the choice of material for bag filter housings plays a significant role in their performance. Common materials include stainless steel, carbon steel, and plastic, each offering distinct advantages depending on the application. Stainless steel, for example, is highly resistant to corrosion and is often preferred in environments where chemical exposure is a concern. On the other hand, plastic housings may be more suitable for less demanding applications due to their lightweight and cost-effective nature.

In conclusion, selecting the appropriate type of liquid bag filter housing is essential for achieving effective filtration. By understanding the various options available, including single-bag, multi-bag, duplex, and specialized housings, users can make informed decisions that align with their specific needs. Ultimately, the right choice not only enhances filtration efficiency but also contributes to the overall success of the operational process.

Key Features To Consider When Selecting Liquid Bag Filter Housings

When selecting liquid bag filter housings, it is essential to consider several key features that can significantly impact the efficiency and effectiveness of the filtration process. One of the primary factors to evaluate is the material of the housing itself. Common materials include stainless steel, carbon steel, and polypropylene, each offering distinct advantages depending on the application. For instance, stainless steel is renowned for its durability and resistance to corrosion, making it ideal for harsh environments or applications involving aggressive chemicals. Conversely, polypropylene may be more suitable for less demanding conditions due to its lightweight nature and cost-effectiveness.

In addition to material, the design of the housing plays a crucial role in its performance. A well-designed housing should facilitate easy bag replacement and maintenance, which is vital for minimizing downtime in industrial processes. Features such as quick-release clamps or hinged covers can enhance accessibility, allowing operators to change filter bags swiftly and efficiently. Furthermore, the design should ensure a secure seal to prevent bypass, which can compromise the filtration process and lead to contamination of the filtered liquid.

Another important consideration is the size and capacity of the liquid bag filter housing. The housing must be appropriately sized to accommodate the required flow rate and the specific dimensions of the filter bags being used. It is essential to match the housing size with the application’s demands to ensure optimal performance. Additionally, understanding the maximum pressure rating of the housing is critical, as it must withstand the operational conditions without risk of failure. This aspect is particularly important in high-pressure applications, where inadequate housing could lead to catastrophic results.

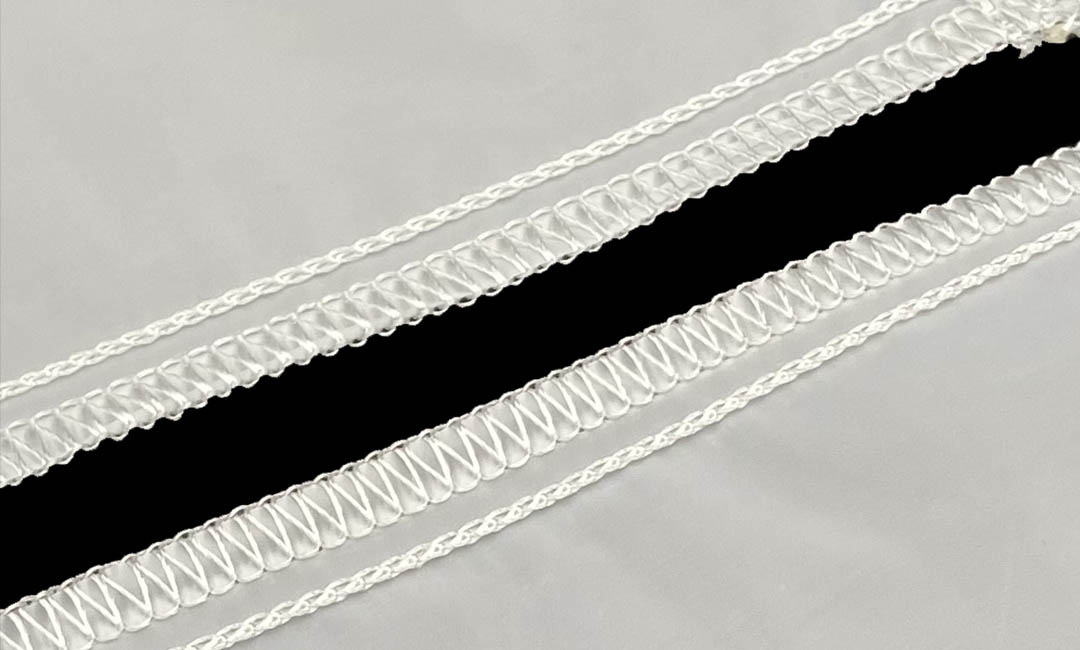

Moreover, the filtration efficiency is a key feature to assess when selecting liquid bag filter housings. Different applications may require varying levels of filtration, and it is crucial to choose a housing that can accommodate the desired filter bag micron rating. This ensures that the housing can effectively remove particulates and contaminants from the liquid, thereby maintaining the quality of the end product. It is also beneficial to consider the compatibility of the housing with various filter bag types, as this flexibility can enhance operational efficiency.

In addition to these technical specifications, it is advisable to evaluate the manufacturer’s reputation and the availability of support services. A reputable manufacturer will provide not only high-quality products but also comprehensive customer support, including installation guidance and troubleshooting assistance. This support can be invaluable, particularly for organizations that may not have extensive experience with liquid filtration systems.

Finally, cost considerations cannot be overlooked. While it may be tempting to opt for the least expensive option, it is essential to weigh the initial investment against the long-term benefits of durability, efficiency, and maintenance costs. A higher-quality housing may result in lower operational costs over time due to reduced downtime and fewer replacements.

In conclusion, selecting the right liquid bag filter housing involves a careful assessment of various key features, including material, design, size, filtration efficiency, manufacturer reputation, and cost. By taking the time to evaluate these factors, organizations can ensure they choose a housing that meets their specific needs, ultimately leading to improved filtration performance and operational efficiency.

Benefits Of Using Liquid Bag Filter Housings In Filtration Systems

Liquid bag filter housings play a crucial role in various filtration systems, offering numerous benefits that enhance the efficiency and effectiveness of liquid filtration processes. One of the primary advantages of using liquid bag filter housings is their ability to provide a high level of filtration efficiency. These systems are designed to capture a wide range of particulate contaminants, including sediment, dirt, and other impurities, ensuring that the filtered liquid meets the required quality standards. The use of bag filters allows for a larger surface area compared to traditional cartridge filters, which translates to a higher dirt-holding capacity. Consequently, this feature reduces the frequency of filter changes, leading to lower operational costs and minimized downtime.

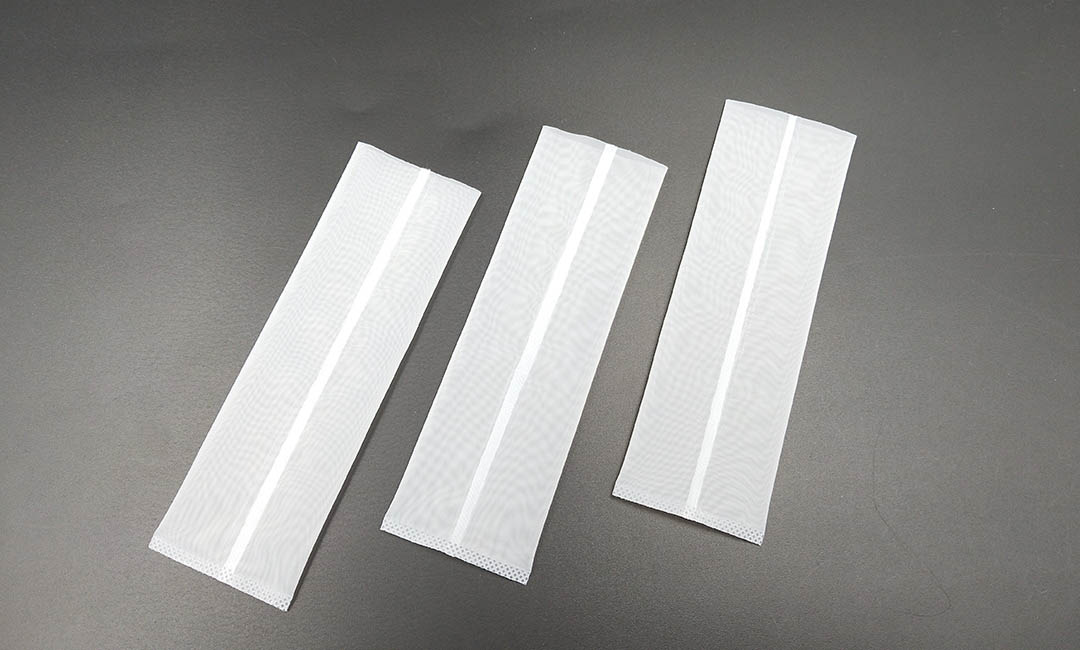

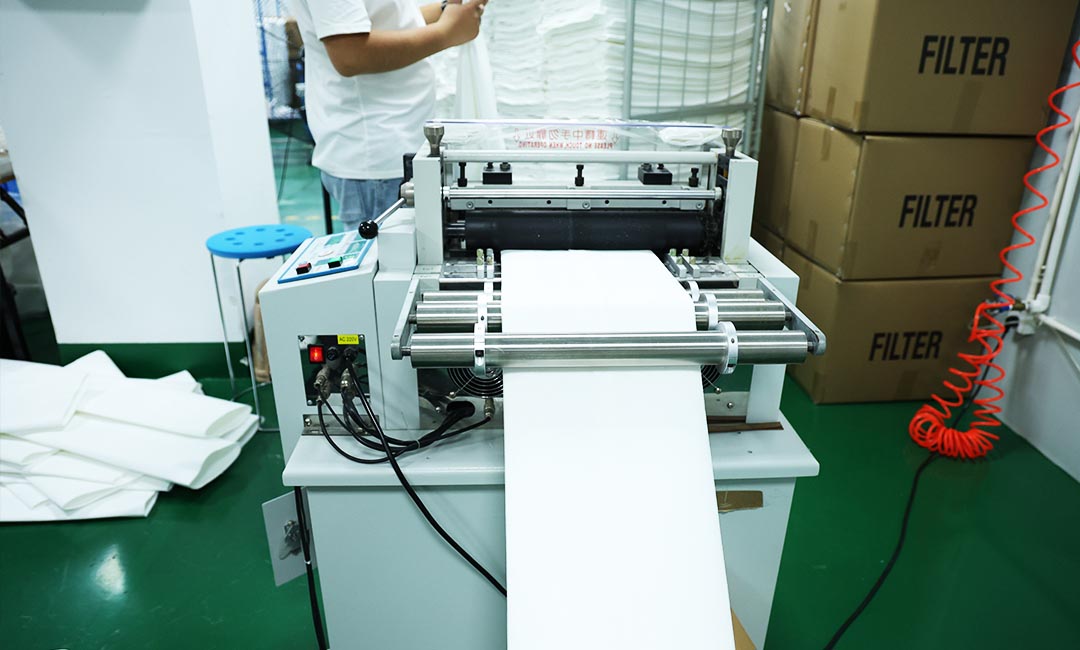

Moreover, liquid bag filter housings are known for their versatility. They can accommodate various bag sizes and filter media, making them suitable for a wide array of applications across different industries, including food and beverage, pharmaceuticals, chemicals, and water treatment. This adaptability allows businesses to customize their filtration systems according to specific needs, ensuring optimal performance regardless of the liquid being processed. Additionally, the ease of installation and maintenance associated with these housings further enhances their appeal. Most liquid bag filter housings are designed for quick and straightforward filter changes, which not only saves time but also reduces labor costs.

Another significant benefit of liquid bag filter housings is their ability to handle high flow rates. This characteristic is particularly important in industrial applications where large volumes of liquid need to be filtered efficiently. The robust construction of these housings allows them to withstand high pressures and flow rates without compromising performance. As a result, industries can maintain productivity levels while ensuring that the quality of the filtered liquid remains high. Furthermore, the design of liquid bag filter housings often includes features such as pressure gauges and drain ports, which facilitate monitoring and maintenance, thereby enhancing operational reliability.

In addition to their practical advantages, liquid bag filter housings contribute to environmental sustainability. By effectively removing contaminants from liquids, these systems help prevent pollution and protect water resources. This is particularly relevant in industries where wastewater treatment is critical. By ensuring that effluents meet regulatory standards before discharge, businesses can minimize their environmental impact and promote sustainable practices. Moreover, the longevity of bag filters, combined with their ability to be reused or recycled, further supports eco-friendly initiatives.

Cost-effectiveness is another compelling reason to consider liquid bag filter housings in filtration systems. While the initial investment may be higher than some alternatives, the long-term savings associated with reduced filter replacement frequency, lower maintenance costs, and improved operational efficiency often outweigh the upfront expenses. Additionally, the enhanced filtration performance can lead to better product quality, which is essential for maintaining customer satisfaction and compliance with industry standards.

In conclusion, the benefits of using liquid bag filter housings in filtration systems are manifold. From their high filtration efficiency and versatility to their ability to handle high flow rates and contribute to environmental sustainability, these systems offer significant advantages for various industries. As businesses continue to prioritize efficiency, cost-effectiveness, and environmental responsibility, liquid bag filter housings will undoubtedly remain a vital component of modern filtration solutions. By investing in these systems, companies can ensure that they meet both operational and regulatory requirements while enhancing the overall quality of their products.

Maintenance Tips For Liquid Bag Filter Housings

Maintaining liquid bag filter housings is essential for ensuring optimal performance and longevity of the filtration system. Regular maintenance not only enhances the efficiency of the filters but also minimizes the risk of system failures and costly downtime. To begin with, it is crucial to establish a routine inspection schedule. This should include checking for any signs of wear and tear, leaks, or corrosion on the housing. By identifying potential issues early, operators can address them before they escalate into more significant problems.

In addition to routine inspections, it is important to monitor the pressure differential across the filter bags. A significant increase in pressure can indicate that the bags are becoming clogged and may need to be replaced. Regularly recording pressure readings allows for better tracking of filter performance and can help in predicting when maintenance is required. Furthermore, operators should familiarize themselves with the specific pressure limits recommended by the manufacturer, as exceeding these limits can lead to damage to the filter housing and the filtration system as a whole.

Another critical aspect of maintenance involves the proper handling and replacement of filter bags. When changing out filter bags, it is essential to follow the manufacturer’s guidelines to ensure that the new bags are installed correctly. Improper installation can lead to bypassing, where unfiltered liquid flows past the filter, compromising the quality of the output. Additionally, operators should always wear appropriate personal protective equipment (PPE) when handling used filter bags, as they may contain hazardous materials.

Cleaning the filter housing is also a vital maintenance task that should not be overlooked. Over time, contaminants can accumulate within the housing, potentially affecting the performance of the filtration system. Depending on the application and the type of contaminants being filtered, it may be necessary to clean the housing regularly. This can be done using a suitable cleaning solution and following the manufacturer’s recommendations for cleaning procedures. Ensuring that the housing is free from debris and buildup will help maintain the integrity of the filtration process.

Moreover, it is advisable to keep a detailed maintenance log for the liquid bag filter housing. This log should include information on inspection dates, pressure readings, bag replacement schedules, and any cleaning or repairs performed. By maintaining a comprehensive record, operators can identify trends over time, which can inform future maintenance strategies and improve overall system reliability.

In addition to these practical tips, it is beneficial to invest in training for personnel responsible for the maintenance of liquid bag filter housings. Proper training ensures that staff are knowledgeable about the equipment, understand the importance of maintenance, and are familiar with best practices. This investment in human resources can lead to improved operational efficiency and a reduction in the likelihood of errors during maintenance tasks.

Ultimately, the maintenance of liquid bag filter housings is a multifaceted process that requires attention to detail and a proactive approach. By implementing a routine inspection schedule, monitoring pressure differentials, ensuring proper bag handling, cleaning the housing regularly, and maintaining detailed records, operators can significantly enhance the performance and lifespan of their filtration systems. With these strategies in place, organizations can ensure that their liquid bag filter housings operate at peak efficiency, thereby safeguarding the quality of their processes and products.