Finding the Perfect Match: Rosin Press Bag Size vs. Plate Size

Benefits of Using a Larger Rosin Press Bag Size

When it comes to rosin pressing, the size of the rosin press bag plays a crucial role in determining the quality and yield of the final product. While many factors contribute to the overall success of a rosin press, the size of the bag is often overlooked. In this article, we will explore the benefits of using a larger rosin press bag size and how it can impact the overall efficiency of the pressing process.

One of the main advantages of using a larger rosin press bag size is the increased capacity for material. A larger bag allows for more material to be pressed at once, which can result in higher yields and a more efficient pressing process. This is especially beneficial for those who are looking to press larger quantities of material at once, as it can save time and energy in the long run.

Additionally, using a larger rosin press bag size can help to ensure a more even distribution of pressure across the material being pressed. When using a smaller bag, there is a higher risk of uneven pressure distribution, which can result in lower yields and a lower quality final product. By using a larger bag, you can help to minimize this risk and achieve more consistent results with each press.

Another benefit of using a larger rosin press bag size is the ability to press larger pieces of material. When using a smaller bag, you may be limited in the size of material that you can press at once. This can be particularly problematic for those who are looking to press larger buds or pieces of material, as they may not fit comfortably within the confines of a smaller bag. By using a larger bag, you can press larger pieces of material with ease, allowing for more flexibility in the types of material that you can press.

In addition to these benefits, using a larger rosin press bag size can also help to reduce the risk of blowouts during the pressing process. Blowouts occur when the pressure inside the bag becomes too high, causing the material to burst out of the bag and potentially contaminate the final product. By using a larger bag, you can help to reduce the risk of blowouts and ensure a cleaner pressing process overall.

Overall, the size of the rosin press bag plays a significant role in determining the success of the pressing process. By using a larger bag, you can increase the capacity for material, achieve more even pressure distribution, press larger pieces of material, and reduce the risk of blowouts. These benefits can help to improve the overall efficiency and quality of the pressing process, making it a worthwhile investment for those looking to achieve the best possible results.

Plate Size Considerations for Different Types of Material

When it comes to choosing the right rosin press bag size, one of the key considerations is the plate size of your press. The plate size of your rosin press will determine the amount of material that can be pressed at one time, as well as the overall efficiency and quality of your rosin extraction process. In this article, we will explore the importance of plate size when selecting the appropriate rosin press bag size for different types of material.

The plate size of your rosin press is crucial when it comes to determining the amount of material that can be pressed at one time. Larger plate sizes allow for more material to be pressed, resulting in higher yields and increased efficiency. However, it is important to note that larger plate sizes may also require larger rosin press bags in order to accommodate the increased amount of material being pressed.

For smaller plate sizes, such as those found in handheld or portable rosin presses, smaller rosin press bags are typically used. These smaller bags are designed to fit snugly around the plates, ensuring that the material is evenly distributed and pressed. While smaller plate sizes may result in lower yields compared to larger plate sizes, they are often preferred for their portability and ease of use.

On the other hand, larger plate sizes, such as those found in commercial or industrial rosin presses, require larger rosin press bags in order to accommodate the increased amount of material being pressed. These larger bags are designed to fit around the plates securely, ensuring that the material is evenly distributed and pressed. While larger plate sizes may result in higher yields compared to smaller plate sizes, they are often less portable and may require more space to operate.

When selecting the appropriate rosin press bag size for different types of material, it is important to consider the plate size of your press. For softer, more malleable materials, such as flower or trim, smaller plate sizes may be sufficient. These materials can be easily pressed using smaller rosin press bags, resulting in high-quality rosin extractions.

For harder, more dense materials, such as hash or kief, larger plate sizes may be necessary in order to effectively press the material. These materials require more pressure and heat in order to extract the rosin, which can be achieved with larger plate sizes and corresponding rosin press bags.

In conclusion, when selecting the perfect rosin press bag size for your material, it is important to consider the plate size of your press. Larger plate sizes allow for more material to be pressed at one time, resulting in higher yields and increased efficiency. Smaller plate sizes, on the other hand, are often preferred for their portability and ease of use. By taking into account the plate size of your press, you can ensure that you are selecting the appropriate rosin press bag size for optimal rosin extraction results.

How Plate Size Impacts Yield and Quality of Rosin

When it comes to extracting rosin from cannabis or hemp, the size of the rosin press bag and the plate size are two crucial factors that can significantly impact the yield and quality of the final product. Finding the perfect match between the two is essential for achieving optimal results.

The plate size of a rosin press refers to the size of the heated plates that are used to apply pressure and heat to the material inside the rosin press bag. The larger the plate size, the more material can be pressed at once, resulting in higher yields. However, larger plate sizes can also lead to uneven pressure distribution and lower quality rosin if not properly managed.

On the other hand, the size of the rosin press bag determines the amount of material that can be pressed at once. Smaller bags are ideal for pressing small amounts of material, while larger bags are better suited for larger quantities. The size of the bag also affects the pressure distribution and the quality of the rosin, as too much material in a small bag can lead to blowouts and lower yields.

When choosing the right combination of rosin press bag size and plate size, it is important to consider the type of material being pressed, the desired yield, and the quality of the final product. For example, if you are pressing high-quality flower or hash, a smaller bag and plate size may be more suitable to preserve the terpenes and cannabinoids. On the other hand, if you are pressing trim or lower-quality material, a larger bag and plate size may be more appropriate to maximize yield.

It is also important to consider the pressure and temperature settings of the rosin press when determining the ideal bag and plate size. Higher pressures and temperatures require larger bags and plates to accommodate the expansion of the material during the pressing process. Lower pressures and temperatures, on the other hand, may allow for smaller bags and plates to be used without compromising yield or quality.

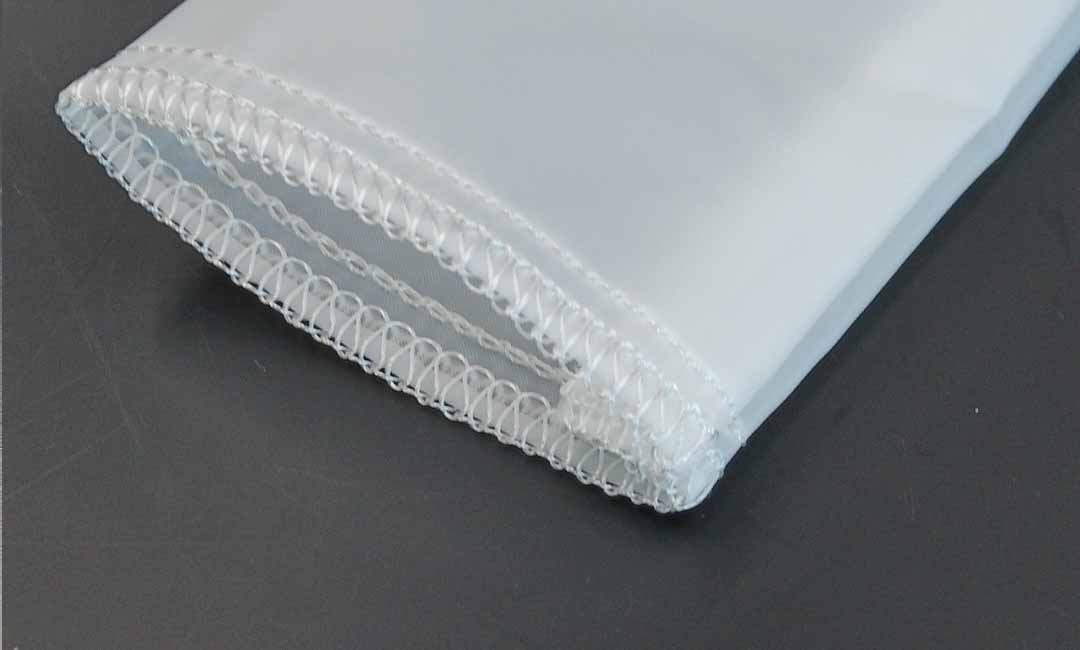

In addition to the size of the bag and plate, the material of the bag is also an important factor to consider. Nylon and polyester bags are commonly used for pressing rosin, as they are durable and heat-resistant. However, some users prefer using natural materials such as silk or hemp for a more environmentally friendly option.

Ultimately, finding the perfect match between rosin press bag size and plate size requires experimentation and fine-tuning. It is important to test different combinations to determine which setup produces the best results for your specific needs and preferences. By carefully considering the factors mentioned above and making adjustments as needed, you can achieve optimal yields and quality when pressing rosin.

Finding the Ideal Combination of Rosin Press Bag Size and Plate Size

When it comes to extracting rosin from cannabis or hemp, finding the perfect match between rosin press bag size and plate size is crucial. The size of the rosin press bag and the plate size can greatly impact the quality and yield of your rosin extraction. In this article, we will explore the importance of finding the ideal combination of rosin press bag size and plate size to achieve the best results.

First and foremost, it is important to understand the role that rosin press bags play in the extraction process. Rosin press bags are used to contain the material being pressed, whether it be flower, hash, or kief. The size of the rosin press bag will determine how much material can be pressed at once, as well as the surface area that the material is pressed against. Choosing the right size rosin press bag is essential for maximizing yield and quality.

When selecting a rosin press bag size, it is important to consider the size of the plates on your rosin press. The plate size will determine the maximum size of the rosin press bag that can be used effectively. If the rosin press bag is too small for the plates, it may not be able to contain the material properly, resulting in a messy extraction process and potentially lower yields. On the other hand, if the rosin press bag is too large for the plates, it may not be able to apply enough pressure to the material, leading to lower yields and lower quality rosin.

Finding the ideal combination of rosin press bag size and plate size is a balancing act. It is important to choose a rosin press bag that is slightly smaller than the plates to ensure a tight fit and proper containment of the material. This will help to maximize pressure and heat distribution, resulting in a more efficient extraction process and higher quality rosin.

In addition to size, it is also important to consider the material and micron size of the rosin press bag. Different materials and micron sizes can affect the quality and yield of the rosin extraction. For example, nylon rosin press bags are known for their durability and ability to withstand high temperatures, while also allowing for good flow of rosin. On the other hand, polyester rosin press bags are known for their high heat resistance and ability to produce clean and pure rosin.

When choosing a rosin press bag, it is important to consider the material and micron size that will best suit your extraction needs. Experimenting with different materials and micron sizes can help you determine which combination works best for your specific material and extraction process.

In conclusion, finding the perfect match between rosin press bag size and plate size is essential for achieving the best results in rosin extraction. By choosing the right size rosin press bag and plate size, as well as considering the material and micron size of the rosin press bag, you can maximize yield and quality in your rosin extractions. Experimenting with different combinations and fine-tuning your process will help you find the ideal combination for your specific needs.