High Flow Cartridges: Advanced Technology for Modern Filtration Needs

Benefits of Using High Flow Cartridges in Industrial Filtration Systems

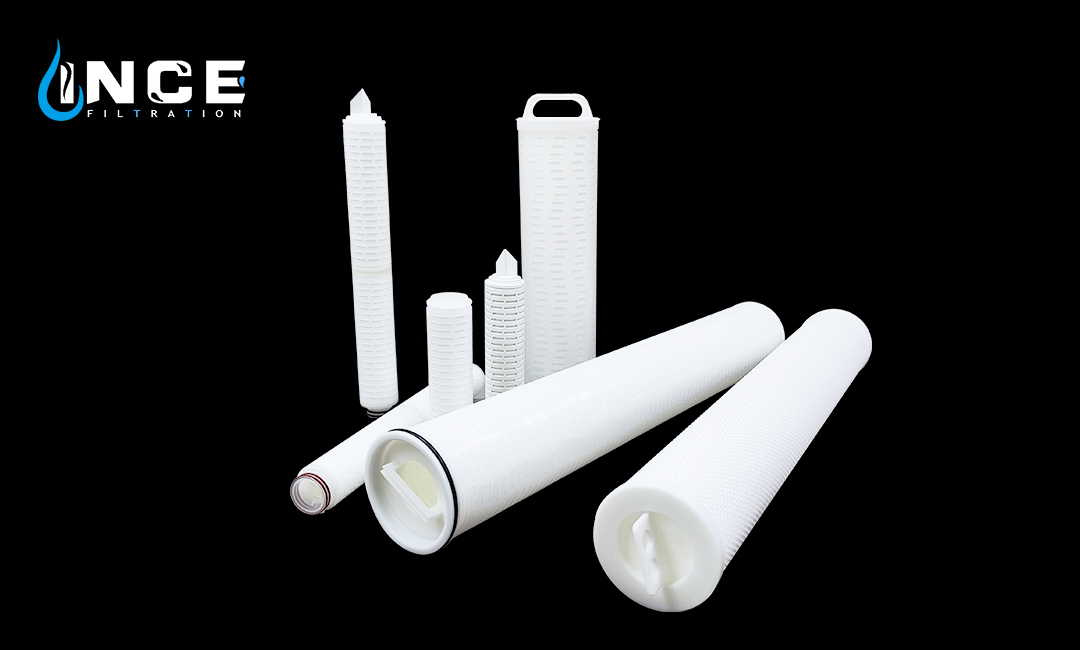

High flow cartridges have become an essential component in modern industrial filtration systems due to their advanced technology and numerous benefits. These cartridges are designed to handle high flow rates while maintaining efficiency and effectiveness in removing contaminants from various liquids. In this article, we will explore the benefits of using high flow cartridges in industrial filtration systems.

One of the key advantages of high flow cartridges is their ability to handle a large volume of liquid flow. Traditional filtration systems may struggle to keep up with high flow rates, leading to decreased efficiency and increased maintenance costs. High flow cartridges, on the other hand, are specifically designed to handle high flow rates without compromising on filtration performance. This means that industrial processes can run smoothly and efficiently without the risk of contaminants entering the system.

Another benefit of using high flow cartridges is their extended lifespan. These cartridges are constructed using durable materials that can withstand high flow rates and harsh operating conditions. As a result, they require less frequent replacement compared to traditional filter cartridges. This not only reduces maintenance costs but also minimizes downtime and ensures continuous operation of industrial processes.

In addition to their durability, high flow cartridges offer superior filtration performance. These cartridges are designed with a larger surface area and higher dirt-holding capacity, allowing them to capture more contaminants and particles from the liquid. This results in cleaner and purer liquid output, which is crucial for industries that require high-quality products or adhere to strict regulatory standards.

Furthermore, high flow cartridges are easy to install and replace, making them a cost-effective solution for industrial filtration systems. Their simple design and compatibility with standard filter housings allow for quick and hassle-free installation. Additionally, the longer lifespan of high flow cartridges means that they do not need to be replaced as frequently, reducing overall maintenance costs and downtime.

High flow cartridges also offer flexibility in terms of customization and compatibility with different filtration systems. These cartridges come in various sizes, configurations, and filtration ratings to meet the specific needs of different industries and applications. Whether it is for water treatment, chemical processing, or food and beverage production, high flow cartridges can be tailored to suit the requirements of any industrial process.

Overall, the benefits of using high flow cartridges in industrial filtration systems are clear. From handling high flow rates to providing superior filtration performance and extended lifespan, these cartridges offer a cost-effective and efficient solution for modern filtration needs. With their advanced technology and versatility, high flow cartridges have become a staple in industrial processes that require reliable and high-quality filtration.

How High Flow Cartridges Improve Efficiency and Cost Savings in Filtration Processes

High flow cartridges have revolutionized the field of filtration by offering advanced technology that improves efficiency and cost savings in industrial processes. These cartridges are designed to handle high flow rates while maintaining optimal filtration performance, making them ideal for a wide range of applications.

One of the key benefits of high flow cartridges is their ability to handle large volumes of fluid without sacrificing filtration quality. Traditional filters often struggle to maintain efficiency at high flow rates, leading to frequent replacements and increased maintenance costs. High flow cartridges, on the other hand, are specifically engineered to handle high flow rates without compromising on filtration performance. This not only reduces downtime and maintenance costs but also ensures consistent and reliable filtration results.

In addition to their superior performance, high flow cartridges also offer significant cost savings compared to traditional filters. Because they can handle higher flow rates, fewer cartridges are needed to achieve the same level of filtration. This means lower initial investment costs and reduced ongoing maintenance expenses. Furthermore, the longer lifespan of high flow cartridges means less frequent replacements, further reducing operational costs over time.

Another advantage of high flow cartridges is their compact design, which allows for more efficient use of space in filtration systems. Traditional filters often require large housing units to accommodate multiple cartridges, which can be cumbersome and take up valuable floor space. High flow cartridges, on the other hand, are designed to fit into smaller housings while still maintaining high flow rates and filtration efficiency. This not only saves space but also simplifies installation and maintenance processes.

Furthermore, high flow cartridges are easy to install and replace, making them a convenient and user-friendly option for industrial filtration systems. Their simple design and compatibility with standard filter housings make them a versatile choice for a wide range of applications. This ease of use not only saves time and labor costs but also ensures that filtration systems can be quickly and efficiently maintained for optimal performance.

Overall, high flow cartridges offer a superior solution for modern filtration needs, combining advanced technology with cost-effective and efficient performance. Their ability to handle high flow rates, reduce maintenance costs, save space, and provide ease of use make them an ideal choice for a wide range of industrial applications. By investing in high flow cartridges, businesses can improve their filtration processes, increase efficiency, and achieve significant cost savings in the long run.

Comparing High Flow Cartridges to Traditional Filtration Methods

High flow cartridges represent a significant advancement in filtration technology, offering numerous advantages over traditional filtration methods. As industries increasingly demand efficient and effective filtration solutions, understanding the differences between high flow cartridges and conventional systems becomes essential. Traditional filtration methods, such as bag filters and pleated cartridges, have long been the standard in various applications, but they often come with limitations that high flow cartridges effectively address.

One of the primary distinctions between high flow cartridges and traditional filtration methods lies in their design and operational efficiency. High flow cartridges are engineered to handle larger volumes of fluid while maintaining a consistent flow rate. This capability is particularly beneficial in applications where high throughput is necessary, such as in water treatment facilities or food and beverage processing. In contrast, traditional filtration systems may struggle to maintain optimal flow rates under similar conditions, leading to increased pressure drops and reduced efficiency. Consequently, industries that rely on high flow cartridges can achieve better performance and lower operational costs.

Moreover, the surface area of high flow cartridges is typically greater than that of traditional filters. This increased surface area allows for more contaminants to be captured without clogging, which is a common issue with conventional filtration methods. As a result, high flow cartridges can operate for extended periods before requiring replacement, thereby reducing maintenance frequency and associated costs. In contrast, traditional filters often necessitate more frequent changes, leading to increased downtime and operational disruptions. This aspect of high flow cartridges not only enhances efficiency but also contributes to a more sustainable approach to filtration by minimizing waste.

In addition to their operational advantages, high flow cartridges also offer improved versatility. They can be utilized in a wide range of applications, from industrial processes to municipal water treatment, making them a more adaptable solution compared to traditional methods. While conventional filters may be designed for specific applications, high flow cartridges can be tailored to meet diverse filtration needs, accommodating various fluid types and contaminant levels. This flexibility is particularly valuable in industries that require rapid adjustments to their filtration systems in response to changing conditions.

Furthermore, the materials used in high flow cartridges often exhibit superior chemical compatibility compared to those found in traditional filters. This characteristic is crucial in industries where the filtration of aggressive chemicals or high-temperature fluids is necessary. High flow cartridges can be constructed from advanced materials that withstand harsh environments, ensuring longevity and reliability. In contrast, traditional filtration methods may not offer the same level of resilience, leading to potential failures and increased costs associated with replacements.

As industries continue to evolve, the demand for more efficient and effective filtration solutions will only grow. High flow cartridges stand out as a modern alternative to traditional filtration methods, providing enhanced performance, reduced maintenance, and greater versatility. By embracing this advanced technology, businesses can not only improve their operational efficiency but also contribute to a more sustainable future. In conclusion, while traditional filtration methods have served their purpose over the years, the advantages offered by high flow cartridges make them an increasingly attractive option for modern filtration needs. As the landscape of filtration technology continues to advance, high flow cartridges are poised to play a pivotal role in meeting the challenges of contemporary industries.

Case Studies Highlighting the Success of High Flow Cartridges in Various Industries

High flow cartridges have revolutionized the field of filtration by providing advanced technology that meets the modern needs of various industries. These cartridges are designed to handle high flow rates while maintaining efficiency and effectiveness in removing contaminants from liquids. In this article, we will explore some case studies that highlight the success of high flow cartridges in different industries.

One industry that has benefited greatly from the use of high flow cartridges is the food and beverage industry. In this industry, it is crucial to maintain high levels of cleanliness and purity in order to ensure the safety and quality of the products being produced. High flow cartridges have been instrumental in achieving this goal by effectively removing impurities and contaminants from liquids such as water, juices, and syrups.

For example, a large beverage manufacturing company was facing challenges with maintaining the quality of their products due to high levels of contaminants in their water supply. By implementing high flow cartridges in their filtration system, they were able to significantly reduce the levels of impurities in their water, resulting in a noticeable improvement in the taste and quality of their beverages. This not only helped them meet regulatory standards but also enhanced their reputation among consumers.

Another industry that has seen success with high flow cartridges is the pharmaceutical industry. In this highly regulated industry, it is essential to have reliable filtration systems in place to ensure the purity of pharmaceutical products. High flow cartridges have proven to be a valuable asset in achieving this goal by providing efficient and consistent filtration of liquids used in the production of medications.

A pharmaceutical company was experiencing issues with maintaining the required levels of purity in their drug manufacturing process. By switching to high flow cartridges, they were able to achieve the desired level of filtration efficiency, resulting in a significant reduction in product defects and rejections. This not only saved them time and money but also improved the overall quality of their products, leading to increased customer satisfaction.

In the oil and gas industry, high flow cartridges have also played a crucial role in ensuring the efficiency and reliability of filtration systems. With the high flow rates and harsh operating conditions in this industry, it is essential to have filtration systems that can handle the demands of the environment. High flow cartridges have proven to be up to the task by providing robust and durable filtration solutions that can withstand the rigors of oil and gas operations.

A major oil and gas company was facing challenges with maintaining the cleanliness of their hydraulic systems due to high levels of contaminants in their fluids. By incorporating high flow cartridges into their filtration system, they were able to effectively remove impurities and extend the lifespan of their equipment. This resulted in improved operational efficiency and reduced maintenance costs, ultimately leading to increased profitability for the company.

In conclusion, high flow cartridges have become an essential component in modern filtration systems across various industries. Their advanced technology and efficiency have proven to be invaluable in achieving the desired levels of purity and cleanliness in liquids used in production processes. The case studies highlighted in this article demonstrate the success of high flow cartridges in improving the quality, efficiency, and reliability of filtration systems in the food and beverage, pharmaceutical, and oil and gas industries. As technology continues to advance, high flow cartridges will undoubtedly play a vital role in meeting the evolving filtration needs of modern industries.