High Flow Filter Cartridge Applications: From Food to Pharmaceuticals

Benefits of High Flow Filter Cartridges in Food Processing

High Flow Filter Cartridge Applications: From Food to Pharmaceuticals

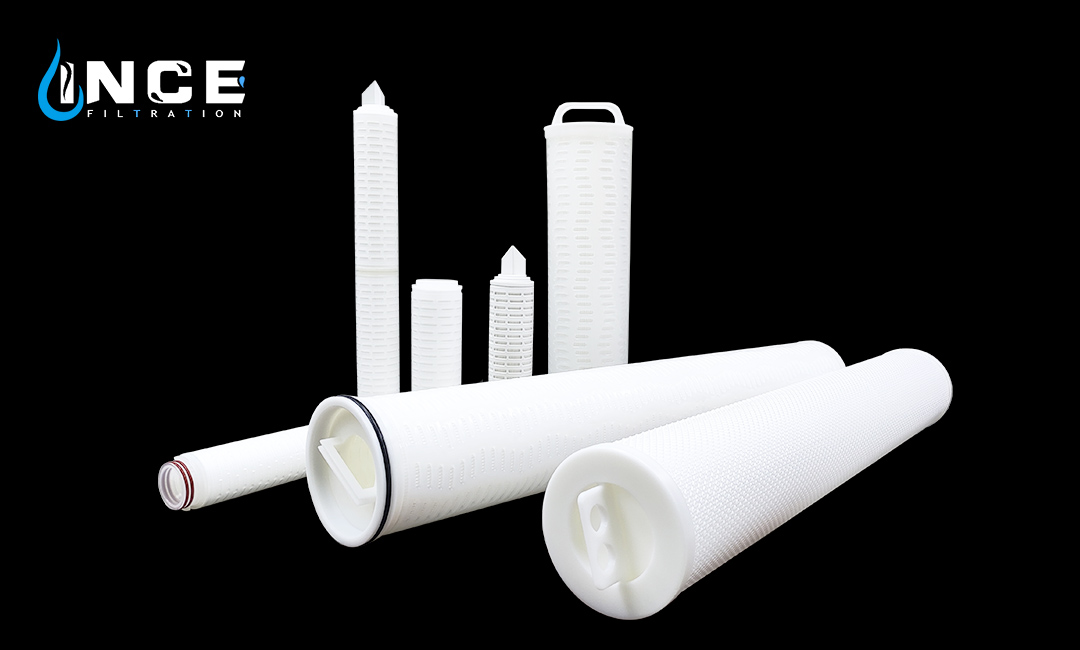

High flow filter cartridges are an essential component in various industries, including food processing. These cartridges offer numerous benefits that make them a popular choice for filtering applications in the food industry. In this article, we will explore the advantages of using high flow filter cartridges in food processing and how they contribute to maintaining high-quality standards.

One of the primary benefits of high flow filter cartridges is their ability to handle large volumes of liquid. In food processing, where large quantities of liquids need to be filtered, high flow filter cartridges provide an efficient solution. These cartridges have a larger surface area compared to traditional filters, allowing for a higher flow rate. This means that more liquid can be filtered in a shorter amount of time, increasing productivity and reducing downtime.

Another advantage of high flow filter cartridges is their superior filtration efficiency. These cartridges are designed to remove even the smallest particles from liquids, ensuring that the final product is free from contaminants. In the food industry, where product quality is of utmost importance, high flow filter cartridges play a crucial role in maintaining the desired standards. By effectively removing impurities, these cartridges help prevent spoilage, improve taste, and extend the shelf life of food products.

High flow filter cartridges also offer cost savings in the long run. Due to their larger surface area and higher flow rate, fewer cartridges are required to achieve the desired filtration capacity. This means lower initial investment costs and reduced maintenance expenses. Additionally, the longer lifespan of high flow filter cartridges compared to traditional filters further contributes to cost savings. With fewer cartridge replacements needed, downtime is minimized, and production efficiency is maximized.

Furthermore, high flow filter cartridges are designed to be easy to install and replace. Their simple design allows for quick and hassle-free cartridge changes, minimizing production interruptions. This ease of use is particularly beneficial in the fast-paced food processing industry, where time is of the essence. Additionally, high flow filter cartridges are compatible with various filtration systems, making them a versatile choice for different food processing applications.

In addition to their applications in liquid filtration, high flow filter cartridges can also be used for gas filtration in the food industry. These cartridges effectively remove contaminants such as dust, bacteria, and odors from the air, ensuring a clean and safe working environment. By maintaining air quality, high flow filter cartridges contribute to the overall hygiene and safety of food processing facilities.

In conclusion, high flow filter cartridges offer numerous benefits in food processing applications. Their ability to handle large volumes of liquid, superior filtration efficiency, cost savings, and ease of use make them an ideal choice for maintaining high-quality standards in the food industry. Whether it is filtering liquids or purifying air, high flow filter cartridges play a crucial role in ensuring the safety and quality of food products. With their versatility and efficiency, it is no wonder that high flow filter cartridges are widely used in various industries, from food to pharmaceuticals.

High Flow Filter Cartridge Applications in Beverage Production

High Flow Filter Cartridge Applications in Beverage Production

High flow filter cartridges play a crucial role in the beverage production industry. These cartridges are designed to remove impurities and contaminants from liquids, ensuring that the final product meets the highest quality standards. From water to juices and even alcoholic beverages, high flow filter cartridges are used in various stages of the production process.

One of the primary applications of high flow filter cartridges in beverage production is water treatment. Water is a key ingredient in the production of beverages, and it needs to be free from any impurities that could affect the taste, odor, or overall quality of the final product. High flow filter cartridges are used to remove sediment, chlorine, bacteria, and other contaminants from the water, ensuring that it is clean and safe for consumption.

In addition to water treatment, high flow filter cartridges are also used in the filtration of juices. Juices, whether they are made from fruits or vegetables, often contain pulp, seeds, and other solid particles that need to be removed to achieve a smooth and clear product. High flow filter cartridges with the appropriate micron rating can effectively remove these particles, resulting in a juice that is visually appealing and free from any unwanted solids.

Alcoholic beverages, such as beer and wine, also benefit from the use of high flow filter cartridges. These cartridges are used to remove yeast, bacteria, and other microorganisms that can affect the taste and stability of the final product. By ensuring that the beverage is free from any unwanted contaminants, high flow filter cartridges contribute to the overall quality and shelf life of alcoholic beverages.

Another important application of high flow filter cartridges in beverage production is the filtration of carbonated drinks. Carbonated drinks, such as soda and sparkling water, contain dissolved gases that give them their characteristic fizz. However, these gases can also carry impurities that need to be removed to maintain the desired taste and quality. High flow filter cartridges are used to remove these impurities, ensuring that the carbonated drinks are clean and refreshing.

Furthermore, high flow filter cartridges are used in the production of energy drinks and sports beverages. These beverages often contain additives, such as vitamins, minerals, and flavorings, which need to be dissolved and mixed thoroughly. High flow filter cartridges with a large surface area and high flow rates are used to achieve efficient mixing and dispersion of these additives, ensuring that they are evenly distributed throughout the beverage.

In conclusion, high flow filter cartridges have a wide range of applications in the beverage production industry. From water treatment to the filtration of juices, alcoholic beverages, carbonated drinks, and energy drinks, these cartridges play a crucial role in ensuring that the final products meet the highest quality standards. By removing impurities and contaminants, high flow filter cartridges contribute to the overall taste, appearance, and stability of beverages. Whether it is in the production of soft drinks, juices, or alcoholic beverages, high flow filter cartridges are an essential component of the beverage production process.

High Flow Filter Cartridges for Water Treatment in Pharmaceuticals

High flow filter cartridges are an essential component in various industries, including pharmaceuticals. These cartridges play a crucial role in ensuring the purity and quality of water used in pharmaceutical manufacturing processes. In this article, we will explore the applications of high flow filter cartridges in water treatment for pharmaceuticals.

Water is a critical ingredient in pharmaceutical manufacturing, used for various purposes such as cleaning, rinsing, and as a raw material in the production of drugs. The quality of water used in pharmaceutical processes directly impacts the safety and efficacy of the final product. Contaminants in water, such as bacteria, viruses, and particulates, can compromise the quality of pharmaceutical products and pose a risk to public health.

High flow filter cartridges are designed to effectively remove contaminants from water, ensuring that it meets the stringent purity requirements of the pharmaceutical industry. These cartridges are capable of filtering large volumes of water at high flow rates, making them ideal for use in pharmaceutical manufacturing facilities where a continuous supply of clean water is essential.

One of the key applications of high flow filter cartridges in pharmaceutical water treatment is the removal of particulate matter. Particulates can enter the water supply through various sources, such as incoming water from municipal sources or as a byproduct of the manufacturing process. High flow filter cartridges are designed to capture and retain particulates of various sizes, ensuring that the water is free from visible impurities.

In addition to particulate removal, high flow filter cartridges are also effective in removing microorganisms from water. Bacteria, viruses, and other pathogens can pose a significant risk to pharmaceutical products if they are present in the water supply. High flow filter cartridges are equipped with advanced filtration media that can effectively remove microorganisms, ensuring that the water used in pharmaceutical processes is free from harmful contaminants.

Another important application of high flow filter cartridges in pharmaceutical water treatment is the removal of organic and inorganic contaminants. Organic contaminants such as pesticides, solvents, and pharmaceutical residues can enter the water supply through various sources and can be difficult to remove using conventional filtration methods. High flow filter cartridges are designed to effectively remove organic contaminants, ensuring that the water used in pharmaceutical processes is free from harmful substances.

Inorganic contaminants such as heavy metals, salts, and minerals can also pose a risk to pharmaceutical products if they are present in the water supply. High flow filter cartridges are capable of removing inorganic contaminants through a combination of physical filtration and chemical adsorption, ensuring that the water meets the purity requirements of the pharmaceutical industry.

In conclusion, high flow filter cartridges play a crucial role in ensuring the purity and quality of water used in pharmaceutical manufacturing processes. These cartridges are designed to effectively remove particulates, microorganisms, organic contaminants, and inorganic contaminants from water, ensuring that it meets the stringent purity requirements of the pharmaceutical industry. By using high flow filter cartridges in water treatment, pharmaceutical manufacturers can ensure the safety and efficacy of their products and protect public health.

High Flow Filter Cartridge Applications in Chemical Manufacturing

High flow filter cartridges are essential components in various industries, including chemical manufacturing. These filters play a crucial role in ensuring the quality and purity of products by removing contaminants and impurities from liquids. In this article, we will explore the applications of high flow filter cartridges in chemical manufacturing and how they contribute to the overall efficiency and effectiveness of the production process.

One of the primary applications of high flow filter cartridges in chemical manufacturing is in the filtration of process water. Water is a critical component in many chemical processes, and its quality can significantly impact the final product. High flow filter cartridges are used to remove suspended solids, bacteria, and other impurities from process water, ensuring that it meets the required purity standards. This helps to prevent contamination of products and equipment, leading to higher product quality and reduced downtime.

In addition to process water filtration, high flow filter cartridges are also used in the filtration of various chemicals and solvents. Many chemical manufacturing processes involve the use of different chemicals and solvents, which need to be filtered to remove impurities and ensure their purity. High flow filter cartridges are designed to handle a wide range of chemicals and solvents, making them ideal for use in chemical manufacturing applications. By removing contaminants from chemicals and solvents, these filters help to maintain product quality and consistency, leading to higher yields and reduced waste.

Another important application of high flow filter cartridges in chemical manufacturing is in the filtration of process gases. Many chemical processes involve the use of gases, which need to be filtered to remove impurities and ensure their purity. High flow filter cartridges are used to remove particulates, moisture, and other contaminants from process gases, ensuring that they meet the required quality standards. This helps to prevent equipment corrosion, improve process efficiency, and maintain product quality.

High flow filter cartridges are also used in the filtration of raw materials and intermediates in chemical manufacturing. Raw materials and intermediates used in chemical processes often contain impurities that need to be removed to ensure product quality. High flow filter cartridges are used to remove contaminants from raw materials and intermediates, ensuring that the final product meets the required purity standards. This helps to prevent product defects, improve process efficiency, and reduce waste.

In conclusion, high flow filter cartridges play a crucial role in chemical manufacturing by ensuring the quality and purity of products. These filters are used in the filtration of process water, chemicals, solvents, process gases, raw materials, and intermediates, helping to maintain product quality, improve process efficiency, and reduce waste. By investing in high-quality high flow filter cartridges, chemical manufacturers can enhance the overall efficiency and effectiveness of their production processes, leading to higher yields, lower costs, and improved product quality.