High Flow Filter Cartridge Maintenance: Tips for Longevity

Importance of Regular Cleaning

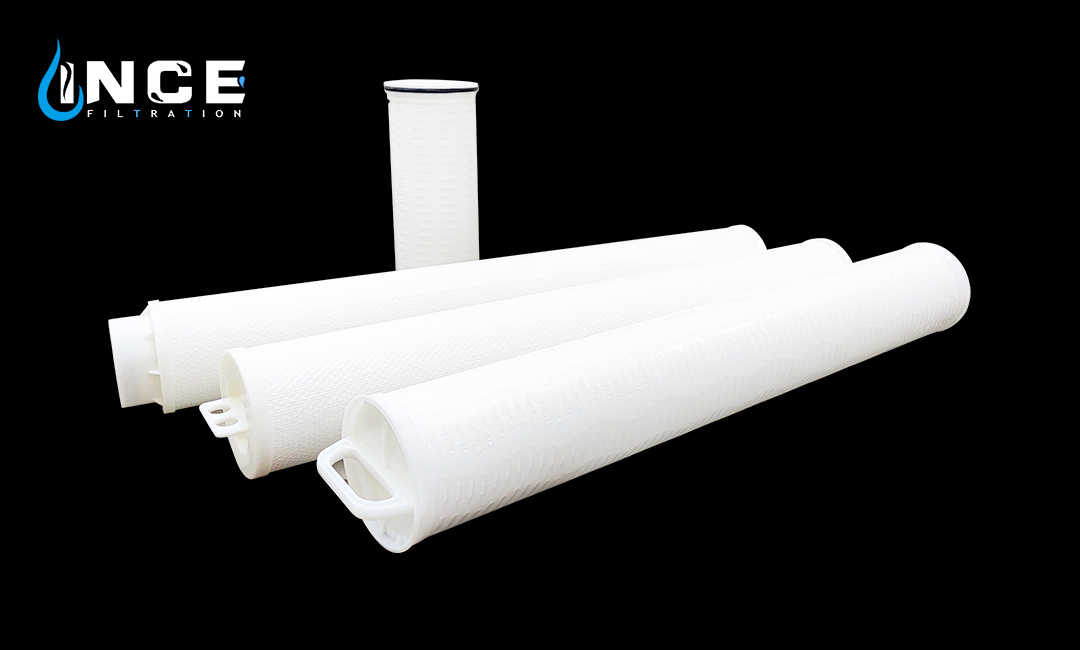

High flow filter cartridges are essential components in many industrial and commercial applications, providing efficient filtration of liquids and gases. Regular maintenance of these filter cartridges is crucial to ensure optimal performance and longevity. In this article, we will discuss the importance of regular cleaning for high flow filter cartridges and provide some tips for maintaining their effectiveness.

One of the primary reasons for regular cleaning of high flow filter cartridges is to prevent clogging. Over time, dirt, debris, and other contaminants can accumulate on the surface of the filter media, reducing the flow rate and efficiency of the cartridge. By cleaning the filter cartridge regularly, you can remove these contaminants and restore its performance.

Another important reason for regular cleaning is to extend the life of the filter cartridge. When a filter cartridge becomes clogged, it puts additional strain on the filtration system, leading to increased wear and tear. By cleaning the filter cartridge regularly, you can prevent premature failure and ensure that it continues to operate effectively for an extended period.

In addition to preventing clogging and extending the life of the filter cartridge, regular cleaning also helps to maintain the quality of the filtered product. Contaminants that accumulate on the surface of the filter media can affect the purity of the filtered liquid or gas, compromising the quality of the final product. By cleaning the filter cartridge regularly, you can ensure that the filtered product meets the required standards and specifications.

To maintain the effectiveness of high flow filter cartridges, it is important to follow some key maintenance tips. Firstly, it is essential to establish a regular cleaning schedule based on the operating conditions and the level of contamination. For heavily contaminated applications, more frequent cleaning may be required to prevent clogging and maintain optimal performance.

When cleaning high flow filter cartridges, it is important to use the appropriate cleaning method and equipment. Depending on the type of contaminants and the filter media, different cleaning techniques such as backwashing, flushing, or chemical cleaning may be required. It is important to follow the manufacturer’s recommendations for cleaning to avoid damaging the filter cartridge.

In addition to regular cleaning, it is also important to inspect the filter cartridge periodically for signs of wear or damage. Cracks, tears, or other defects in the filter media can compromise the filtration efficiency and lead to contamination of the filtered product. By inspecting the filter cartridge regularly, you can identify any issues early and take corrective action to prevent further damage.

Proper storage of high flow filter cartridges is also essential for maintaining their effectiveness. When not in use, filter cartridges should be stored in a clean, dry environment to prevent contamination and damage. It is important to follow the manufacturer’s recommendations for storage to ensure that the filter cartridges remain in good condition.

In conclusion, regular cleaning and maintenance of high flow filter cartridges are essential for ensuring optimal performance and longevity. By following the tips outlined in this article, you can prevent clogging, extend the life of the filter cartridge, and maintain the quality of the filtered product. Remember to establish a regular cleaning schedule, use the appropriate cleaning methods, inspect the filter cartridge periodically, and store it properly to maximize its effectiveness. With proper maintenance, high flow filter cartridges can continue to provide efficient filtration for your industrial or commercial applications.

Proper Storage Techniques

High flow filter cartridges are essential components in many industrial and commercial applications, providing efficient filtration of liquids and gases. To ensure the longevity and effectiveness of these filter cartridges, proper maintenance is crucial. One key aspect of maintenance is proper storage techniques. In this article, we will discuss some tips for storing high flow filter cartridges to maximize their lifespan and performance.

First and foremost, it is important to store high flow filter cartridges in a clean and dry environment. Moisture and contaminants can compromise the integrity of the filter media and reduce its effectiveness. Therefore, it is recommended to store filter cartridges in a climate-controlled area with low humidity levels. Additionally, the storage area should be free from dust, dirt, and other particles that could potentially clog the filter media.

When storing high flow filter cartridges, it is also important to protect them from exposure to direct sunlight and extreme temperatures. UV rays can degrade the filter media over time, while high temperatures can cause the filter material to break down prematurely. Therefore, it is best to store filter cartridges in a shaded area away from heat sources such as heaters or direct sunlight.

Another important aspect of proper storage is to ensure that the filter cartridges are stored in their original packaging or in a protective container. This helps to prevent damage to the filter media and ensures that the cartridges remain clean and free from contaminants. If the original packaging is not available, consider using a plastic bag or a sealed container to protect the filter cartridges from dust and debris.

In addition to proper storage conditions, it is also important to handle high flow filter cartridges with care when storing them. Avoid dropping or mishandling the cartridges, as this can damage the filter media and reduce their effectiveness. When moving or transporting filter cartridges, use caution and handle them gently to prevent any damage.

Furthermore, it is recommended to label and organize filter cartridges when storing them to keep track of their usage and expiration dates. This helps to ensure that older cartridges are used first and that expired cartridges are not inadvertently used, which could compromise the filtration process. Additionally, keeping a record of when filter cartridges were installed and replaced can help to track their performance and determine when they need to be replaced.

In conclusion, proper storage techniques are essential for maintaining the longevity and effectiveness of high flow filter cartridges. By storing filter cartridges in a clean, dry, and protected environment, handling them with care, and keeping track of their usage, you can maximize the lifespan of these essential filtration components. Remember to follow these tips to ensure that your high flow filter cartridges continue to perform at their best and provide efficient filtration for your industrial or commercial applications.

Replacement Schedule

High flow filter cartridges are an essential component of many industrial and commercial filtration systems. These cartridges are designed to handle high flow rates while effectively removing contaminants from liquids. To ensure the longevity and efficiency of your high flow filter cartridges, proper maintenance is crucial. One key aspect of maintenance is adhering to a regular replacement schedule.

Regularly replacing high flow filter cartridges is essential to ensure that they continue to perform at their best. Over time, filter cartridges can become clogged with contaminants, reducing their effectiveness and potentially causing damage to the filtration system. By replacing filter cartridges on a regular schedule, you can prevent these issues and ensure that your filtration system continues to operate efficiently.

The frequency of filter cartridge replacement will depend on a variety of factors, including the type of contaminants being filtered, the flow rate of the system, and the quality of the filter cartridges themselves. In general, it is recommended to replace high flow filter cartridges every 6 to 12 months. However, it is important to monitor the condition of the cartridges regularly and adjust the replacement schedule as needed.

One way to determine when it is time to replace a filter cartridge is to monitor the pressure drop across the cartridge. As a filter cartridge becomes clogged with contaminants, the pressure drop will increase. By regularly monitoring the pressure drop, you can identify when a cartridge is becoming clogged and needs to be replaced. Additionally, if you notice a decrease in the flow rate of your filtration system, this may also indicate that it is time to replace the filter cartridges.

When replacing high flow filter cartridges, it is important to follow the manufacturer’s recommendations for installation. This may include properly aligning the cartridges, ensuring a tight seal, and priming the cartridges before use. By following these guidelines, you can ensure that the cartridges are installed correctly and will perform at their best.

In addition to regular replacement, there are a few other maintenance tips that can help extend the life of your high flow filter cartridges. One important tip is to regularly clean the filter housing to remove any buildup of contaminants. This will help prevent clogs and ensure that the cartridges can operate efficiently. Additionally, it is important to monitor the condition of the filter cartridges and replace them promptly when needed.

By following these maintenance tips and adhering to a regular replacement schedule, you can ensure the longevity and efficiency of your high flow filter cartridges. Proper maintenance is essential to keep your filtration system operating at its best and to prevent costly repairs or replacements in the future. With regular maintenance, you can extend the life of your filter cartridges and ensure that your filtration system continues to perform effectively.

Monitoring Pressure Levels

High flow filter cartridges are essential components in many industrial processes, helping to remove impurities and contaminants from liquids and gases. To ensure the longevity and effectiveness of these filters, proper maintenance is crucial. One key aspect of maintenance is monitoring pressure levels within the filter cartridge.

Pressure levels can provide valuable insights into the condition of the filter cartridge and indicate when it may need to be replaced or cleaned. By regularly monitoring pressure levels, you can prevent damage to the filter cartridge and ensure that it continues to operate efficiently.

One of the first steps in monitoring pressure levels is to establish a baseline pressure reading when the filter cartridge is new and clean. This baseline reading will serve as a reference point for future pressure measurements. As the filter cartridge accumulates contaminants and debris, the pressure levels will gradually increase. By comparing current pressure readings to the baseline reading, you can determine when the filter cartridge needs to be replaced or cleaned.

It is important to monitor pressure levels regularly, as sudden spikes in pressure can indicate a problem with the filter cartridge or the filtration system as a whole. High pressure levels can lead to reduced flow rates, decreased filtration efficiency, and potential damage to the filter cartridge. By catching these issues early, you can prevent costly repairs and downtime.

In addition to monitoring pressure levels, it is also important to keep an eye on the differential pressure across the filter cartridge. Differential pressure is the difference in pressure between the inlet and outlet of the filter cartridge and is a key indicator of filter performance. A high differential pressure can indicate that the filter cartridge is becoming clogged and may need to be replaced or cleaned.

Regularly monitoring pressure levels and differential pressure can help you identify potential issues with the filter cartridge before they escalate. By staying proactive and addressing problems early on, you can extend the life of the filter cartridge and ensure that it continues to operate at peak efficiency.

When monitoring pressure levels, it is important to use a reliable pressure gauge or monitoring system. Make sure that the pressure gauge is properly calibrated and that it is installed in a location where it can provide accurate readings. Regularly check the pressure gauge for any signs of damage or wear and replace it if necessary.

In conclusion, monitoring pressure levels is a critical aspect of high flow filter cartridge maintenance. By establishing a baseline pressure reading, regularly monitoring pressure levels, and keeping an eye on the differential pressure, you can ensure the longevity and effectiveness of your filter cartridge. By staying proactive and addressing issues early on, you can prevent costly repairs and downtime. Invest in a reliable pressure gauge and make pressure monitoring a regular part of your maintenance routine to keep your filter cartridge operating at peak efficiency.